10 Things Every Manager Should Know About Supply Replacement

You want your team to run smoothly, right? When you replace supplies at the right time, you keep shelves full, costs in check, and your operations moving. Little changes make a big difference to efficiency. Take a moment to think about how you handle your current supply replacement. Do you spot gaps before they become problems, or do you sometimes get caught out?

Key Takeaways

Set clear goals for your supply replacement process. This helps you work better and stay focused. Match your supply chain plan with your business goals. This makes your team quick and responsible. Decide how you will measure success. This helps you see how well your supply chain works. It also shows where you can do better. Look for signs that things are not working well, like delays or mistakes. This helps you know when to replace supplies. Watch your inventory closely. This stops you from running out of stock and keeps things running smoothly. Use demand forecasting to guess what customers will need. Change your supply plans to fit these needs. Use technology, like automation and data analytics, to make your supply replacement easier. Build good relationships with suppliers by talking often and being flexible. This makes your supply chain more reliable.

Set Clear Objectives

Setting clear objectives is the first step in making your supply replacement process work for you. When you know what you want to achieve, you can make better decisions and keep your team on track. Good planning helps you avoid confusion and keeps your supply chain management running smoothly. Let’s look at how you can align your goals and measure your progress.

Align with Business Goals

You want your supply replacement strategy to support your company’s bigger picture. If you match your planning with your business goals, you will see better results. Here’s how this alignment can help:

Improves efficiency and focus. When you link your supply chain management to your main strategy, you use your resources wisely. You cut down on waste and avoid doing the same work twice.

Enhances agility. If your planning matches your goals, you can react quickly when things change. You can adjust your supply chain planning without slowing down.

Increases accountability. When everyone knows their role in the strategy, it’s easier to track progress. You can see who is responsible for each part and check if you are meeting your targets.

Tip: Review your supply chain management objectives every few months. This helps you spot gaps and keeps your process of ongoing improvement on track.

You should always look for ways to boost efficiency. Make sure your planning supports your business goals, and you will see ongoing improvement in your results.

Define Success Metrics

How do you know if your supply replacement strategy is working? You need clear metrics to gauge supply chain efficiency. These numbers show you what’s going well and where you need to improve. Here are some key metrics to watch:

Inventory carry rate

Months of supply on hand

Inventory-to-sales ratio (ISR)

Carrying cost of inventory

Inventory turnover rate

Perfect order rate

Inventory accuracy

Fill rate

Tracking these metrics to gauge supply chain efficiency gives you a clear picture of your progress. You can spot problems early and make changes before they grow. Good planning means you always know where you stand.

Note: Don’t just set your metrics and forget them. Commit to continuous improvement. Use your data to guide your planning and keep your supply chain management strong.

If you want more tips, try sharing your strategy with your team. Ask for feedback and use it as part of your process of ongoing improvement. When you commit to continuous improvement, you make your supply chain planning stronger every day.

Recognise When to Replace Supplies

Knowing when to replace supplies can make or break your daily operations. If you wait too long, you risk running out of what you need. If you act too soon, you might waste money and space. Let’s look at how you can spot the right time to act.

Signs of Inefficiency

You might think your process works fine, but small problems can build up over time. Watch for these signs that tell you it’s time to replace supplies:

You notice frequent delays in getting materials or products.

Your team spends extra time searching for items that should be on hand.

You see more mistakes, like picking the wrong item or running out of stock.

Your costs start to creep up, but you can’t see why.

Customers complain about late deliveries or missing products.

Tip: Keep a simple checklist. If you tick off more than one of these signs, it’s time to review how you replace supplies.

When you spot these issues, you can act before they become bigger problems. You keep your team happy, your customers satisfied, and your costs under control.

Outdated Processes

Old ways of working can slow you down. If you use outdated methods to replace supplies, you might face several challenges. Here are some common problems you might see:

Production delays stop your team from finishing work on time. This can lead to downtime and higher costs.

Projects run over budget or take longer than planned. Missing key materials can hurt your profits and your reputation.

Customers get frustrated when you can’t deliver on time. They might look for another supplier if you let them down.

Costs go up when you rush orders, fix mistakes, or handle returns. You also spend more time sorting out problems instead of moving forward.

You can use this table to spot where your process might need an update:

Problem | Impact on Business |

|---|---|

Production delays | Higher costs, lost time |

Project overruns | Missed deadlines, lost profit |

Customer dissatisfaction | Lost trust, fewer sales |

Increased costs | Lower margins, wasted effort |

Note: If you see these problems often, your process to replace supplies needs a refresh. Try new tools or update your routine to keep things running smoothly.

When you pay attention to these warning signs, you can replace supplies at the right time. This keeps your business strong and your team ready for anything.

Avoid Stockouts

It is annoying when you run out of something you need. Stockouts slow your team down. They can make customers unhappy. You might lose money if this happens. To stop stockouts, watch your inventory closely. Plan for changes in what people want. Here are ways to work better and keep your shelves full.

Inventory Monitoring

You cannot fix problems you do not notice. Watching your inventory helps you find issues early. When you check your stock, you make better choices. This keeps your business running well. Many companies lose money because they do not check inventory enough.

Manufacturing companies lose about 8% of their yearly money from stockouts.

Small businesses lose around 4% of their yearly money. If a small business makes £400,000 a year, it loses £16,000.

Try these ways to watch your inventory and work better:

Technique | Description |

|---|---|

Safety Stock | Gives you extra stock to help with changes in demand or supply problems. |

Vendor-Managed Inventory (VMI) | Lets your suppliers look after your stock, so you see more and pay less to store things. |

Demand Sensing | Spots changes in demand quickly, so you can react fast and make fewer mistakes. |

Automated Replenishment | Orders new stock when you are low, so you do not have to check all the time. |

Tip: Set alerts for when your stock is low. This helps you spot problems early and keeps your team working.

Using these ways helps you work better and keep your stock healthy. You worry less about stockouts and can focus on growing your business.

Demand Forecasting

Guessing what you need next month does not work. You need a plan. Demand forecasting helps you know what customers will want and when. This makes planning easier and helps you stop stockouts.

Retailers and manufacturers find demand forecasting hard. People change what they buy quickly. Trends change fast. Outside events can mess up your plans. To work better, watch demand closely and change your plans often.

Evidence | Description |

|---|---|

Demand Forecasting Accuracy | Do not check forecasting accuracy during shortages. Watch demand closely to stop shortages happening again. |

Good demand and supply planning helps you:

Talk more with your suppliers and partners.

Plan better for deliveries and making products.

Cut waiting times and stop problems before they start.

Note: Check your forecasts every month. Change your plans if you see sales or trends change.

When you use demand forecasting, you keep your stock balanced and work better. You stop stockouts and keep your customers happy.

Optimise Inventory

Getting your inventory right is not just about having enough stock. You want to avoid having too much or too little. When you focus on inventory optimisation, you keep your business running smoothly and save money at the same time.

Stock Level Balance

You need to find the sweet spot between overstocking and understocking. If you have too much inventory, you waste money and space. If you have too little, you risk running out and letting customers down. Here are some best practices to help you balance your stock levels:

Use demand forecasting to predict what you will sell next.

Try just-in-time inventory management to cut down on extra stock.

Keep a safety stock as a buffer for surprises.

You can also use smart tools and methods to make things easier. Take a look at this table for more ideas:

Best Practice | Description |

|---|---|

Accurate Demand Forecasting | Looks at past sales and trends to help you plan your inventory. |

Just-in-Time Inventory | Orders stock only when you need it, so you do not fill your shelves with extras. |

Safety Stock Strategies | Keeps a small backup supply for emergencies or sudden changes. |

Inventory Management Software | Tracks your stock and helps you reorder at the right time. |

ABC Analysis | Sorts your inventory by value, so you focus on what matters most. |

Multi-Echelon Inventory Optimisation | Checks your whole supply chain to spot where you have too much or too little. |

Performance Metrics | Measures things like turnover and fill rates to keep you on track. |

Tip: Try using inventory monitoring technologies like barcode scanning. These tools give you real-time updates and help you spot problems before they grow.

When you use these methods, you make inventory optimisation part of your daily routine. You will see fewer shortages and less waste.

Just-in-Time Approach

The just-in-time approach means you order inventory only when you need it. This method helps you save money and space. You do not have to worry about piles of unused stock taking up room. Here is how just-in-time inventory can help your business:

Benefit | Explanation |

|---|---|

Reduced holding costs | You spend less on storage, insurance, and labour because you keep less stock on hand. |

Improved cash flow | You free up money for other parts of your business and can react faster to changes. |

Minimized waste | You avoid spoilage and damage, so you lose less and keep your products fresh. |

Optimised warehouse space | You use your space better and can focus on value-added work instead of storing extra stock. |

You might worry about running out, but you can set up safety stock to cover sudden spikes in demand. When you combine just-in-time with good forecasting, you get the best of both worlds. You keep your shelves stocked without wasting money.

Note: Inventory optimisation is not a one-time job. Check your stock levels often and adjust your plans as your business grows.

If you make these changes, you will see your inventory work for you, not against you.

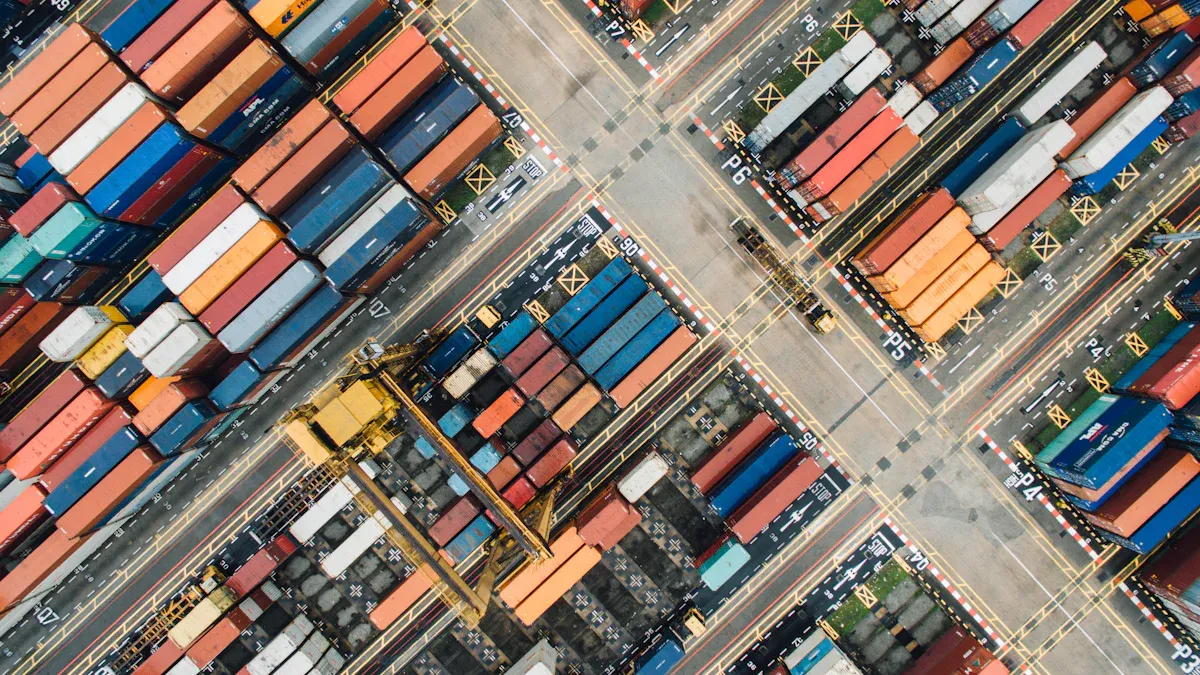

Supply Chain Efficiency

You want your supply chain management to work well. When you focus on supply chain efficiency, you save time and money. Your team is happier too. Let’s see how you can make your supply chain management better.

Streamline Operations

You can make supply chain efficiency better by making things simpler. Look at each step in your supply chain management. Ask, “Does this step help us or slow us down?” If a step is slow or done by hand, think about using automation.

Automation helps a lot. You can use it for inventory management and order processing. You can also use it to track shipments. When you use automation, you get:

Faster supply chain management and fewer errors.

Lower costs because you use resources better.

More correct information about your stock and orders.

Better risk management because you spot problems early.

You should always try to improve your supply chain management. When you look for ways to do better, you find new ways to save money. Your team can do more with less work. You become stronger and ready for anything.

Tip: Try supply chain management software that gives you real-time data. This helps you see problems early and keeps your supply chain efficiency high.

End-to-End Visibility

You need to see your whole supply chain management from start to finish. This is called end-to-end visibility. When you have it, you know what is happening at every step. You can spot problems before they get worse.

With end-to-end visibility, you can:

Cut stockouts in half because you see when you are low.

Watch demand patterns as they change and act fast.

Get early warnings when your inventory is too low.

Work better with your suppliers and avoid problems.

Respond quickly to changes and keep control of your supply chain processes.

Make your customers happier and increase your profits.

Supply chain efficiency gets better when you use real-time data to track your supply chain management. You can see what is happening now, not just last week. This helps you make smart choices and keep your supply chain management strong.

Note: End-to-end visibility is not just about technology. It is about working together with your team and suppliers. When everyone shares information, you get better results.

If you want real supply chain improvement, focus on making your operations simpler and building end-to-end visibility. You will see your supply chain management become more efficient, reliable, and ready for anything.

Leverage Technology

Technology changes how you manage supply replacement. When you use the right tools, you save time and avoid mistakes. You also make your team’s job easier. Let’s look at how automation and data analytics can help you work smarter, not harder.

Automation Tools

You do not have to do everything by hand. Automation tools take care of the boring jobs and let you focus on what matters. Many managers now use these tools to keep their supply chains running smoothly. Here are some of the most common automation tools you can use:

Inventory management software tracks your stock in real time. You always know what you have and what you need to order.

Barcode scanning makes counting and tracking supplies quick and accurate. You cut down on human errors.

Automated picking and packing systems speed up order fulfilment. Your team spends less time searching for items and more time getting orders out the door.

When you use automation, you see big benefits. You make fewer mistakes and get real-time updates on your stock. Your workflow becomes smoother. You can also grow your business without losing quality or service.

Tip: Start small. Try one automation tool first. Once you see the benefits, you can add more tools to your process.

Data Analytics

Data analytics helps you make better decisions. You do not have to guess what will happen next. Instead, you use facts and numbers to guide your choices. This makes your supply replacement process stronger and more reliable.

Data analytics can help you in many ways. It improves demand forecasting, so you can predict what you will need and when. This means you avoid having too much or too little stock. Real-time inventory monitoring gives you insights that support just-in-time strategies. You save money by holding less stock and still meet customer needs. You can also use data to check how well your suppliers perform. You see who delivers on time and who sends the best quality.

Here is how data analytics can boost your supply replacement:

Predictive analytics looks at past sales to help you plan for the future.

You align your supply chain with what your customers want.

You use your resources better, which saves money and keeps customers happy.

Data analytics also helps you spot risks early. For example, you can track traffic or weather in real time. If there is a problem, you change your delivery plans quickly. This keeps your supply chain strong and your customers satisfied.

Note: You do not need to be a data expert. Start by tracking a few key numbers. Over time, you will see patterns that help you make smarter choices.

When you use technology, you make supply replacement easier, faster, and more accurate. Your team works better, and your business grows stronger.

Manage Supplier Relationships

Building strong supplier relationships makes your supply replacement process much smoother. When you work well with your suppliers, you avoid delays and keep your business running. Let’s look at how you can improve your communication and set up flexible terms that benefit both sides.

Communication

Good communication sits at the heart of every successful partnership. If you want your supply replacement to go smoothly, you need to talk openly and listen carefully. You should set up clear roles for your team and your suppliers. This helps everyone know who to contact and what to expect.

Here are some simple ways to boost your communication:

Assign clear roles to each team member. This stops confusion and makes sure everyone knows their job.

Create a communication plan. Decide how often you will talk and what you will discuss. This keeps meetings focused and saves time.

Listen to feedback from your suppliers. They can spot problems early and help you find solutions.

Hold regular meetings. These keep everyone updated and help you solve issues before they grow.

Write down key discussions. This gives you something to look back on if questions come up later.

Make it easy to report problems. If someone spots an issue, they should know how to get help quickly.

Tip: Choose one person to lead your supplier relationships. This person keeps the information flowing and makes sure nothing gets missed.

When you build a solid communication plan, you avoid costly mistakes. You also show your suppliers that you value their input and want to work together.

Flexible Terms

You need flexibility in your contracts to keep your supply chain strong. If you can adjust your agreements, you and your suppliers can handle changes in the market more easily. Flexible terms help you build trust and work better together.

Flexible contracts help you and your suppliers trust each other. You both feel more comfortable sharing ideas and solving problems.

You can negotiate better prices and terms. This saves money and helps your business run more smoothly.

Long-term agreements lower the risk of supply chain problems. You and your suppliers can adapt to changes without stress.

A University of Twente study found: ‘When supplier and buyer commit to a strong relationship, they [can] create value, which could not be created by either of the 2 independently, and [they] improve each other’s performance.’

You should also check your contracts often. Make sure they still fit your needs as your business grows. If you track how well your suppliers perform, you can spot when it’s time to update your agreements.

When you focus on flexible terms, you make your supply replacement more reliable. You and your suppliers can face challenges together and keep your business moving forward.

Control Costs

It is important to keep costs low if you want your supply chain to work well. When you know where your money goes, you can make better choices. This helps your team stay focused on doing a good job. Let’s see how cost analysis and value optimisation can help you get the best results.

Cost Analysis

You must know what you spend and the reasons for it. Cost analysis helps you find waste and ways to work better. You can use different methods to look at your spending and see where you can save money. Here are some good ways to do this:

Spend analysis lets you check all your purchases. You find out which parts of your supply chain cost the most money. This helps you choose where to look for better deals or changes. You can also use what you learn to set new goals for your team.

Should-cost analysis checks what you pay against what you should pay. You look at material costs, labour rates, overhead, and profit margins. If you see a big difference, you can talk to your suppliers and ask for better prices. This keeps your supply chain working well and supports quality.

Cost versus mass analysis looks at the cost for each mass of your supplies. You compare your current suppliers with new ones. If you find a part that costs too much for its size, you can change the design or find a better supplier. This method helps you keep a good balance between efficiency and quality.

Tip: Use these cost analysis methods often. You will notice patterns and set better goals for your team. This keeps your supply chain working well and helps keep customers happy.

Value Optimisation

You want to get the most for your money without losing quality. Value optimisation means you look for ways to work better and keep customers happy. You can use smart ideas to save money and still give good quality.

Here are some ways to optimise value in your supply chain:

Strategy | Description |

|---|---|

Buy more from your best suppliers. You get discounts and better deals. | |

Optimise Inventory Management | Use data to guess what you will need. You avoid having too much or too little stock. |

Streamline Transportation | Put small shipments together into bigger ones. You save on transport costs and work better. |

Identify SMI Opportunities | Build a supply managed inventory programme. Both you and your suppliers benefit. |

Minimise Supplier Risk | Watch your suppliers in real time. You spot risks early and keep your supply chain strong. |

You can also set clear goals for each strategy. This helps you check how well you are doing. When you see good results, you know your value optimisation is working. If you see problems, you can act quickly to keep customers happy.

Note: Value optimisation is not just about saving money. It is about keeping quality high and making sure your customers are happy. When you focus on working well and set the right goals, you build a supply chain that works for everyone.

Risk Management

You never know when a problem might hit your supply chain. That’s why you need a strong risk management plan. If you prepare for trouble, you can keep your business running, even when things go wrong. Let’s look at how you can protect your supply replacement process.

Diversify Sources

Relying on just one supplier for your sourcing can put your business at risk. If that supplier faces a problem, you could see big delays or even stop production. You might also lose your power to negotiate prices or terms. Sometimes, a single supplier’s quality drops, and you have no backup. You could also find their product plans don’t match your needs.

Here are some common risks when you depend on one supplier for sourcing:

You face more disruptions if your supplier has issues, like a fire or strike.

You lose your power to negotiate, so suppliers can raise prices.

You risk quality problems if your only supplier starts making mistakes.

You might not get the products you want if your supplier changes direction.

To avoid these problems, spread your sourcing across several suppliers. This gives you more options and helps you keep control. You can compare prices, check quality, and pick the best fit for your business. When you diversify your sourcing, you build a more flexible and reliable supply chain.

Tip: Review your sourcing partners every year. Make sure you have backups ready in case something changes.

Contingency Planning

You can’t predict every problem, but you can plan for them. A good contingency plan helps you act fast when things go wrong. Start by looking at your sourcing and checking where you might face trouble. Run “what if” scenarios to see how your supply chain would cope.

Here’s how you can build a strong contingency plan:

Invest in software that tracks your sourcing and spots weak points.

Assess your suppliers and test different scenarios to find risks.

Choose flexible transport options and work closely with your sourcing partners.

Test your plans often to make sure they work in real life.

A solid contingency plan is a key part of any strategic supply chain strategy. It helps you stay agile and ready for anything. When you keep testing and improving your plan, you get better at overcoming challenges before they grow.

Note: Keep your team trained on your contingency plans. Practice makes it easier to act quickly when a real problem hits.

Stockouts Prevention

Stockouts can hurt your business and upset your customers. You can stop them by using smart risk management steps. First, improve your demand forecasting. This helps you predict what your customers will want, especially when you launch new products. Share your forecasts with your sourcing partners so they can plan ahead.

Build strong relationships with your suppliers. When you work together, you can spot problems early and fix them before they cause stockouts. Use real-time updates to track your sourcing and deliveries. Set alerts for low stock or sudden changes in demand. Don’t forget to include freight lead times in your reorder points.

Here’s a quick checklist for preventing stockouts:

Use accurate demand forecasting for all your sourcing needs.

Share your plans with suppliers to keep everyone on the same page.

Track shipments in real time and watch for delays.

Set up alerts for low stock or fast-changing demand.

Adjust your sourcing plans as soon as you spot a risk.

Callout: Preventing stockouts is not just about having enough stock. It’s about building a smart, flexible sourcing process that keeps your business moving.

When you focus on mitigating risks, you make your supply chain stronger. You keep your shelves full, your costs down, and your customers happy.

Sustainability Practices

You might think going green is just a trend, but it’s now a big part of running a smart business. When you focus on sustainability practices, you help the planet and make your supply chain stronger. Let’s see how you can make better choices and stay on the right side of the law.

Eco-Friendly Choices

You can make a real difference by picking eco-friendly supplies. These choices help you cut waste, save energy, and keep your team and customers safe. Many companies now check their waste and look for ways to recycle or reuse materials. You can do the same. Here’s a quick look at the main benefits:

Benefit | Description |

|---|---|

You can run waste audits and find ways to recycle or repurpose materials. This means less rubbish goes to landfill. | |

Energy Conservation | Switching to renewable energy, like solar or wind, saves money and lowers your impact on the environment. |

Use of Non-Toxic Materials | Choosing safer, non-toxic supplies keeps pollution down and protects everyone who uses your products. |

You also help the planet in other ways:

You shrink your carbon footprint by using better transport and fewer resources.

You cut down on waste, which makes your supply chain more sustainable.

You use more renewable resources, so you don’t rely as much on fossil fuels.

Tip: Start small. Swap out one or two supplies for greener options. Over time, you’ll see the benefits add up.

Compliance

You need to follow the rules if you want to avoid trouble. Many industries now set strict standards for supply replacement. You should set clear goals, like cutting greenhouse gas emissions. Some big companies, such as General Mills, aim to lower their emissions by 30% in the next ten years. They even want to reach net zero by 2050. You can learn from them.

Here’s what you can do to stay compliant:

Set clear sustainability goals that match global standards.

Add green rules to your buying process.

Talk with your suppliers and check how they perform.

Use tracking systems to see where your products come from.

Replace suppliers who don’t meet your high standards.

Note: When you work closely with your suppliers and set high standards, you build a supply chain that’s ready for the future.

You don’t have to do everything at once. Take small steps, check your progress, and keep improving. That way, you’ll meet the rules and help the planet at the same time.

Tangbuy Advantage

Private Labelling

You want your products to stand out. Tangbuy gives you the power to create your own brand with private labelling. You do not have to settle for generic items. You can choose how your products look, feel, and even taste. This control helps you build a business that feels unique.

Here’s what you get when you use Tangbuy’s private labelling:

You control your branding and product appearance. Pick the colours, packaging, and even the materials.

You save money. Tangbuy cuts out the middlemen, so you keep more profit.

You can react fast to new trends. If your customers want something new, you can change your products quickly.

You create unique offerings. Want to sell flavoured dental floss or special packaging? You can do that.

You stand out in the market. Your products do not look like everyone else’s.

Tip: Try adding a small twist to your product, like a new flavour or a special box. Customers remember brands that feel different.

With Tangbuy, you do not just sell products. You build a brand that people trust and remember.

Brand Identity

Your brand is more than a logo. It is how people see your business. Tangbuy helps you shape your brand identity from the ground up. You can match your products and marketing to your own style. This makes your business feel professional and trustworthy.

Take a look at how Tangbuy supports your brand identity:

Feature/Capability | Description | Benefit for Dropshipping Marketing |

|---|---|---|

Tone Adjustment | Matches your brand’s voice | Keeps your message the same |

Visual Pattern Recognition | Makes your posts look professional | Strong brand identity |

You keep your message clear. Your social media and website look sharp. Customers know what to expect every time they see your brand.

Note: A strong brand identity builds trust. When people trust your brand, they come back for more.

Tangbuy’s approach lets you control every detail. You can make sure your products and marketing always fit your vision. This helps you grow your business and keep your customers happy.

You now know the ten essentials for smart supply replacement. These steps help you keep your business running and your supply chain strong. Try putting these ideas into practice and check your process often. If you want to make things easier, work with a professional provider like Tangbuy. You get:

Fast fulfilment with 24-hour order processing

Seamless Shopify integration for easy scaling

Stay ahead and keep your shelves full. Your team and customers will thank you.

FAQ

What is supply replacement?

Supply replacement means getting new stock when you run low or run out. You keep your shelves full and your team ready. You avoid delays and keep your business moving.

How often should I review my supply replacement process?

You should check your process every few months. This helps you spot problems early. You can fix issues before they grow. Regular reviews keep your supply chain strong.

Why do stockouts happen?

Stockouts happen when you do not have enough stock to meet demand. This can come from poor planning, missed orders, or sudden changes in what customers want. You can prevent most stockouts with good monitoring.

What tools help with supply replacement?

You can use inventory management software, barcode scanners, and automated alerts. These tools help you track stock, spot problems, and order supplies on time. They make your job easier.

How do I choose the right supplier?

Look for suppliers who deliver on time and offer good quality. Check their prices and ask for flexible terms. Build a strong relationship so you can solve problems together.

Can technology really make supply replacement easier?

Absolutely! Technology gives you real-time updates and helps you avoid mistakes. You save time and money. Your team can focus on more important tasks.

What is private labelling, and why should I care?

Private labelling lets you put your own brand on products. You stand out from the crowd and build trust with your customers. Your business feels unique and professional.

Tip: If you have more questions, talk to your team or reach out to a supply chain expert. You do not have to solve everything alone.

TangBuy: A Smarter Way to Dropship in 2025

If you're looking to stay competitive with dropshipping in 2025, speed and trend-awareness are key. TangBuy helps you stay ahead with real-time product trends, fast fulfilment, and factory-direct sourcing. With over 1 million ready-to-ship items, 24-hour order processing, and seamless Shopify integration, TangBuy makes it easier to test, scale, and succeed in today's fast-moving eCommerce landscape.

See Also

Common Supplier Communication Errors And Their Solutions

Ten Errors I Encountered When Beginning My Amazon Journey

Five New Approaches To Find Popular Items For Your Store

Identifying Wholesale Products With High Profit Margins For Success