AI-Driven Supply Chain: Optimizing Sourcing, Manufacturing, and Delivery in One Platform

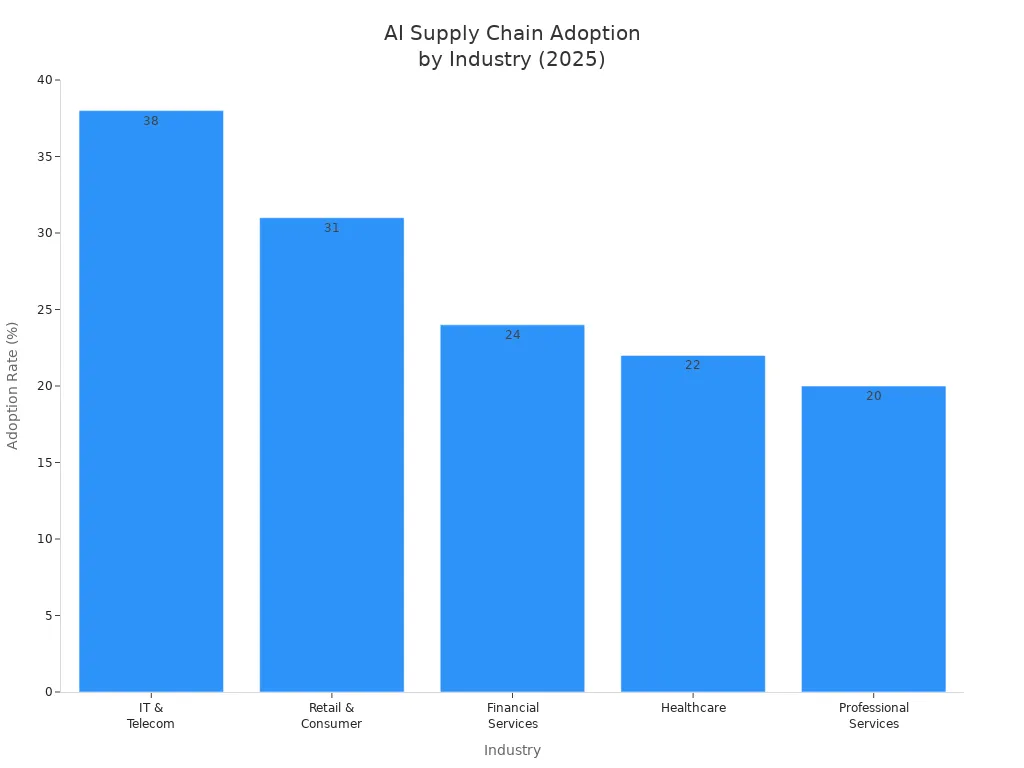

You may see businesses working faster and making better decisions now. This is because AI-driven platforms link each part of the supply chain. They help from finding suppliers to sending out products. You get more done, spend less money, and watch things happen as they go. Most companies want these good things. Just look at the numbers:

Industry | |

|---|---|

IT & Telecom | 38% |

Retail & Consumer | 31% |

Financial Services | 24% |

Healthcare | 22% |

Professional Services | 20% |

AI Supply Chain technology uses predictive analytics and automation. It helps cut costs, stop delays, and keeps things working well.

Key Takeaways

AI-driven supply chains link sourcing, manufacturing, and delivery. This makes businesses work faster and better.

Automated supplier checks with AI save time. They also make choosing suppliers more accurate and quick.

Predictive analytics in AI helps guess demand. This cuts waste and makes sure you have the right stock when needed.

AI watches real-time data to spot risks early. You can fix problems before they stop your work.

Dynamic scheduling in manufacturing makes production better. It saves energy and boosts output. Customers stay happy.

AI improves logistics by finding the best delivery routes. This lowers fuel costs and makes deliveries faster.

Using AI for inventory management keeps stock levels just right. It stops you from having too much or too little stock.

AI helps sustainability by cutting waste and managing energy use. It also makes sure sourcing is ethical in the supply chain.

AI in Sourcing

Supplier Choice

Automated Evaluation

You want to pick the best suppliers, but doing it by hand takes ages. With AI, you can speed up the whole process. AI-driven tools scan supplier data, check their records, and compare them against your needs. You get results in days, not months. For example, Samsung Electronics uses an AI system that checks suppliers across 75 different points. This system cut their selection time in half and made their choices more accurate. You can trust AI to spot the best options and avoid mistakes that come from manual work.

Performance Ranking

AI does not just stop at picking suppliers. It also ranks them based on how well they perform. You see clear scores for quality, delivery speed, and price. This helps you make smart decisions fast. Many companies report a 40% jump in evaluation accuracy and a 30% drop in supply chain problems. You get a list of top suppliers, so you always know who to trust.

Demand Forecasts

Predictive Procurement

Guessing what you need to buy can lead to waste or shortages. AI Supply Chain platforms use smart models to predict demand. These models look at past sales, market trends, and even the weather. You get a clear picture of what to order and when. Here’s a quick look at the most common models:

Model Type | Description |

|---|---|

Time series forecasting | Uses past trends (like ARIMA, exponential smoothing) |

Causal models | Looks at outside factors like price or marketing |

Machine learning models | Uses algorithms such as XGBoost, LSTM, Prophet |

Hybrid approaches | Mixes your data with things like weather or social media |

Neural networks spot tricky patterns in demand.

Deep learning works well even if you do not have much old data.

Stock Optimisation

AI helps you keep just the right amount of stock. It lines up your orders with what customers want. This means you spend less on storage and avoid running out of products. Predictive analytics make your supply chain run smoothly and save you money.

Risk Control

Disruption Detection

You want to avoid surprises. AI watches real-time data from news, weather, and your suppliers. It spots risks early, like delays or shortages. You get alerts before problems grow. This keeps your business running, even when things change fast.

Supplier Risk Mitigation

AI does more than warn you. It suggests ways to fix problems before they hurt your business. It can even sum up risks and offer actions you can take. You move from reacting to problems to stopping them before they start. This makes your supply chain stronger and more flexible.

Did you know? Companies using AI for sourcing see fewer shortages and better supplier relationships. They also save money by finding risks early and acting fast.

You can see the impact in the numbers:

Percentage of Use Cases | Production Status (%) | Average Investment (Million $) | |

|---|---|---|---|

Forecasting and budgeting | 5% | 45% | 1.0 |

Supplier management | 4% | 8% | 2.6 |

Supplier risk assessment and monitoring | 3% | 58% | 2.0 |

AI Supply Chain tools help you work smarter, cut costs, and keep your business safe from surprises.

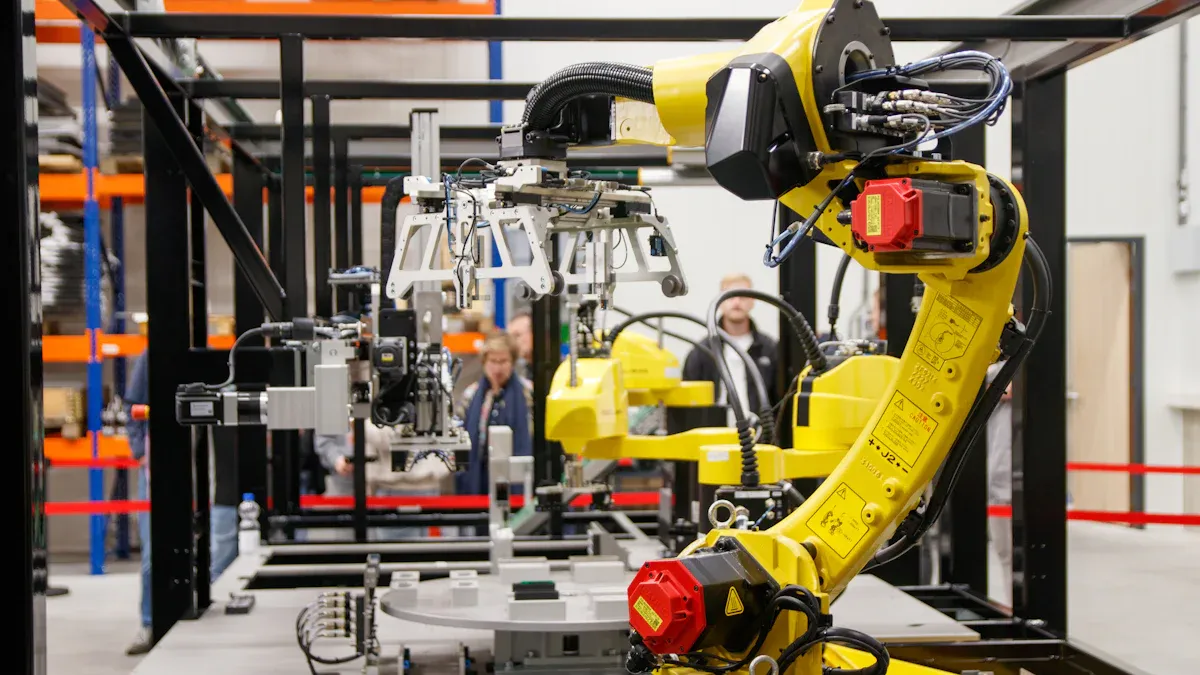

AI in Manufacturing

Planning

Dynamic Scheduling

You want your factory to work well. AI helps you plan your schedule as things happen. It checks orders, machine health, and energy costs. You can change plans fast if something goes wrong. This saves time and uses machines better.

Here is what experts found about AI planning:

Source | Findings |

|---|---|

Journal of Cleaner Production | Neural Networks made factories use 50% less energy. |

IEEE Transactions on Reliability | Reinforcement Learning cut cycle time by up to 40%. |

Control Engineering | AI found problems and doubled output for a car parts maker. |

You make more products, use less energy, and keep customers happy.

Resource Use

AI helps you use materials, time, and energy wisely. It checks what each job needs. You can spot waste and fix it quickly. Some factories saved over 10% energy by letting AI change schedules. You save money and help the planet too.

Quality

Defect Detection

No one wants bad products. AI quality control finds defects people miss. It uses cameras and sensors to check every item. You get results in seconds.

Method | Detection Rate |

|---|---|

AI-Powered Systems | Over 99% |

Manual Inspection | Up to 60% missed |

AI finds almost every problem. Sometimes, it is 99.86% right. Manual checks miss up to 30% of defects. With AI, you give better products and earn trust.

Real-Time Monitoring

AI watches your line all the time. It sends alerts if something is wrong. You can fix issues before they get big. This keeps quality high and customers happy.

Tip: Real-time monitoring helps you see trends and get better every day.

Maintenance

Predictive Upkeep

You do not need to wait for machines to break. AI tells you when equipment needs care. It checks sensor data and warns you. This means fewer surprises and less wasted time.

Strategic Advantage | Quantified Impact |

|---|---|

Lower operational and servicing expenses | 30% less spent on maintenance and 10% on spare parts |

Increased asset uptime and production continuity | 10–20% more machine uptime and availability |

Improved reliability and fewer malfunctions | 70% fewer breakdowns on average |

You spend less on repairs and keep machines running longer.

Downtime Reduction

AI helps you plan fixes at the best time. You do not stop the whole line for small repairs. Some factories cut downtime by up to 15%. You get more done with the same machines. Your team works smarter, not harder.

With AI Supply Chain tools, your factory is faster, safer, and more reliable. You save money, use less energy, and deliver better products every day.

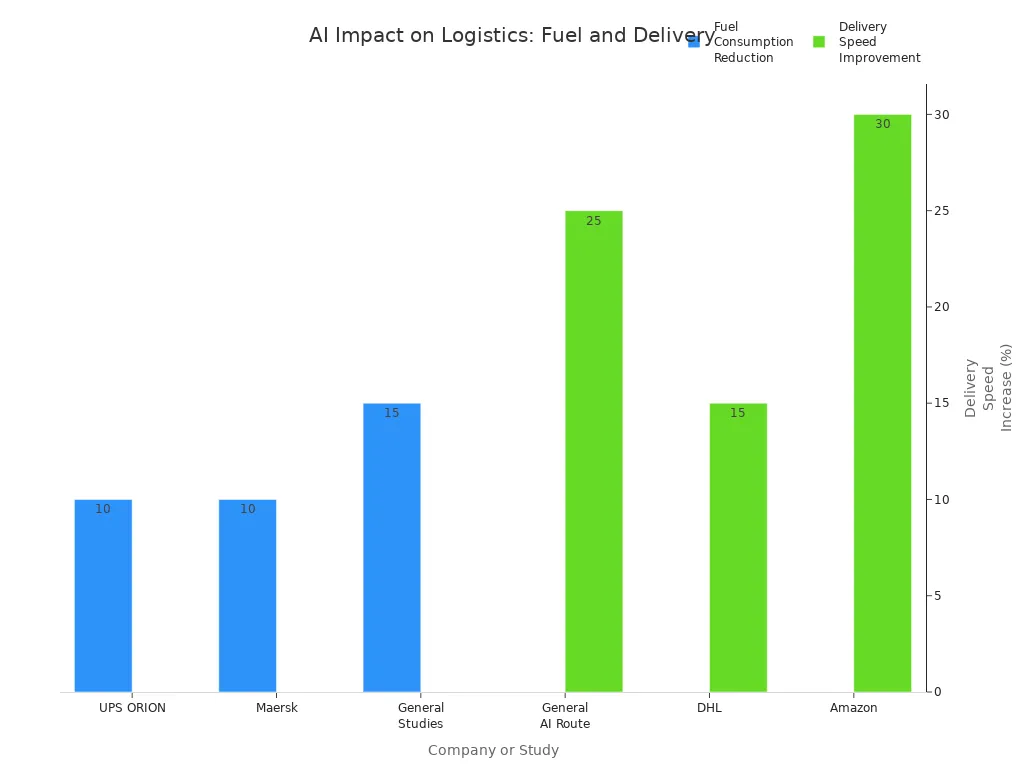

AI in Logistics

Route Optimisation

Traffic Analysis

You want your deliveries to arrive on time, even when roads get busy. AI-powered systems check real-time traffic, weather, and road closures. They pick the best routes for your drivers. You avoid traffic jams and save fuel. Companies like UPS and Maersk use these tools every day. Their drivers spend less time stuck in traffic and more time delivering parcels.

Evidence Type | Statistic/Impact |

|---|---|

Fuel Consumption Reduction | UPS's AI-powered ORION system saves about 10 million gallons of fuel each year. |

Maersk cut fuel costs by up to 15% and reduced use by 10%. | |

Studies show AI route optimisation can lower fuel use by over 15%. | |

Improvements in Delivery Speed | AI route optimisation cuts delivery times by up to 25%. |

DHL saw a 15% rise in on-time deliveries with its AI-powered platform. | |

Amazon's AI use led to a 30% boost in delivery speed. | |

Documented Cost Savings | AI saves money through fuel, labour, and better inventory. |

Cost Planning

AI helps you plan delivery costs before you send out a single van. It checks fuel prices, driver hours, and delivery windows. You see where you can save money. You can also spot costly routes and change them. This means you keep your delivery promises and protect your profits.

Tip: AI route planning lets you deliver faster and spend less. You can even use fewer vehicles for the same number of orders.

Inventory

Stock Automation

You do not want empty shelves or wasted stock. AI-driven inventory management keeps your stock levels just right. It checks sales, demand, and even weather to predict what you need. You get alerts when it is time to restock. You avoid over-ordering and running out.

It cuts errors in forecasts by using real-time data.

You can spot slow-moving products and act fast.

AI-driven inventory management makes restocking easy.

It stops overstock and stockouts by checking data all the time.

Automated systems use demand forecasts and machine learning to predict what you need.

Real-time demand sensing lets you adjust stock levels quickly.

AI cuts waste and overstock by predicting demand well.

Machine learning uses old sales data to guess future needs.

Multi-Site Visibility

You might have stock in many places. AI gives you a clear view of all your warehouses and shops. You see what is selling and where. You can move stock between sites to meet demand. This keeps your customers happy and your shelves full.

Tracking

End-to-End View

You want to know where every parcel is, from the warehouse to the customer’s door. AI-powered tracking gives you a live view of your whole supply chain. You spot delays early and fix them fast. This makes your operations more accurate and saves money.

Real-time data makes your logistics more accurate.

You spend less by cutting human mistakes and extra work.

Your system grows with your business.

Predictive analytics help you avoid risks.

You see your whole supply chain at a glance.

Exception Alerts

Sometimes things go wrong. AI sends you alerts when a parcel is late or a route changes. You can act before your customer even notices. This keeps your service reliable and builds trust.

Note: With an AI Supply Chain, you get faster deliveries, lower costs, and happier customers. You stay ahead of problems and keep your business running smoothly.

AI Supply Chain Integration

When you use one AI platform, all supply chain parts connect. Sourcing, manufacturing, and delivery work together as one system. This helps your business move faster and make smarter choices. You are ready for any problem that comes up. Let’s look at how this works in real life.

Unified Data

Seamless Flow

You do not need to ask different teams for information anymore. One platform puts all your data in one place. Orders, inventory, and supplier details move between teams quickly. Delivery updates are shared right away. You can see what is happening everywhere at the same time.

AI can understand and use documents as they come in. This changes how you run your supply chain.

You can find problems early and fix them before they get worse. For example, one company used an AI platform for planning. They made better forecasts and had fewer shortages. Another business used AI to help planners work 23% faster by using automation.

Central Control

Central control means you run your whole supply chain from one screen. You do not need to use many tools or wait for reports. Everything you need is in one place. This helps you make quick choices and keeps your team working together.

Here is how a single AI platform helps with business planning and testing ideas:

Feature/Benefit | Description |

|---|---|

Real-time Data Integration | One platform links supply chain jobs, so data moves fast and you can see it all. |

Advanced Analytics | It uses analytics to turn data into helpful tips for inventory, orders, and logistics. |

Enhanced Agility | The platform lets you change plans fast, like restocking or changing production. |

You can test “what if” ideas to see what might happen. This helps you get ready for busy times, late suppliers, or sudden big orders.

AI is growing fast at PwC and with clients in every field. In 2025, AI will get even better at quality, accuracy, and automation. These changes will build on each other and speed up growth.

Real-Time Decisions

Insights & Alerts

You want to make good choices quickly. AI gives you live updates and alerts when something needs your attention. You do not have to wait for reports at the end of the day. You see what is happening as it happens.

Benefit | Description |

|---|---|

Data Processing Speed | AI looks at lots of data fast, so you can decide quickly. |

Market Trend Anticipation | AI helps you guess market changes, so you can act in time. |

Logistics Optimisation | AI finds the best routes and times, making logistics work better. |

Inventory Management | You can see your stock in real time and avoid running out or having too much. |

AI helps you spot trends, see problems coming, and act before they cost you money. You can change stock, send shipments a new way, or change production in minutes.

More supply chains will use AI soon, making them react faster.

Real-time stock checks help you see problems before they grow.

AI can make some choices on its own, making logistics better without people.

AI in supply chains has a bright future. Soon, AI will not just guess what might happen. It will also tell you the best thing to do. You can change shipments or stock right away if something goes wrong.

Collaboration

You work better when everyone has the same information. AI platforms let your team, suppliers, and partners share updates easily. Everyone sees the same data. This stops confusion and helps you solve problems faster.

Machine learning and AI help you think and choose faster.

You can chat, share files, and check progress in one place. This keeps everyone working together on the same goals.

The Role of Generative AI in Document Automation

Generative AI handles boring paperwork for you. It reads, fills in, and checks things like invoices, orders, and shipping forms. This saves time and stops mistakes.

Metric | Improvement |

|---|---|

Reduction in invoice processing time | 64% (Milaha) |

Faster processing time | Up to 60% faster |

Reduction in error rates | 90% |

Manual processing of invoices | Over 80% still manual |

Error rates | 5–10% |

Processing time increase | 25% longer |

It does simple jobs, so people make fewer mistakes.

It makes data entry and paperwork more accurate.

It checks rules and laws every time.

It keeps records neat and easy to check.

You spend less time on paperwork and more time growing your business. You also avoid costly mistakes and keep your records tidy for checks.

Did you know? Generative AI can handle invoices up to 60% faster and cut mistakes by 90%. This means less stress for you and your team.

When you use an AI Supply Chain platform, you get one place for all your data, faster choices, and fewer mistakes. You stay ahead of others and keep your customers happy.

AI Supply Chain Benefits

Cost Savings

Lower Expenses

You want to save money across your business. AI Supply Chain platforms help you do just that. When you use AI to manage your supply chain, you cut down on waste, reduce manual work, and spot savings you might miss. Many companies see big results:

Most businesses report operational savings of 35% to 45% after using AI-driven supply chain solutions.

Some companies have saved up to $2.6 trillion globally each year by using AI for cost reduction.

You can lower costs in areas like logistics, warehousing, and supplier management.

Tip: Every pound you save on operations can go straight back into growing your business.

Inventory Costs

Keeping too much stock ties up your money. Not enough stock means you lose sales. AI helps you find the right balance. Here’s how it works:

Demand Forecasting: AI looks at sales, trends, and even the weather to predict what you need.

Dynamic Inventory Optimisation: AI adjusts your stock levels in real time, so you never have too much or too little.

Supply Chain Visibility: You see what’s in your warehouses and shops at any moment, making it easy to move stock where it’s needed.

You spend less on storage and avoid costly stockouts. With better predictions, you can make smarter decisions and keep your shelves just right.

Agility

Fast Response

Markets change quickly. You need to react fast. AI Supply Chain tools help you spot changes and act before your competitors do. When you use AI, you can:

Adjust your orders and deliveries as soon as demand shifts.

Move stock between locations to meet sudden spikes.

Keep your customers happy with quick service.

AI-driven supply chains help you stay flexible. You can handle new trends, sudden sales, or even slow periods without missing a beat. This makes your business more competitive and ready for anything.

Crisis Handling

Problems can happen at any time. Maybe a supplier is late, or a storm blocks your delivery route. AI helps you handle these crises with ease:

Automation in warehouses and shipping means you rely less on manual work, so you respond faster when things go wrong.

Real-time data sharing lets your team and partners see problems as they happen, so everyone can work together to fix them.

Machine learning cuts forecasting errors by 10–20%, so you plan better.

AI improves reaction times to disruptions by 20–30%.

Delivery reliability goes up by 10–20% because AI can spot delays and suggest new routes.

Note: AI and machine learning process huge amounts of data quickly. You get real-time insights, so you can recover from problems faster and keep your business running smoothly.

Customer Value

Delivery Accuracy

Your customers want their orders on time and in perfect condition. AI helps you deliver with precision. Here’s what you get:

Better forecasting means you know what to ship and when.

AI finds the fastest routes for your drivers and the best ways to pick goods in the warehouse.

You reduce mistakes and keep your promises to customers.

Many companies see big improvements in delivery accuracy after adopting AI. You build trust and keep customers coming back.

Personalisation

Every customer is different. AI lets you treat them that way. You can use AI to:

Offer products and deals that match each customer’s needs.

Create tailored experiences that make people feel valued.

Use dynamic pricing and promotions to give the best offers at the right time.

Plan logistics so each customer gets their order how and when they want it.

AI-powered personalisation helps you stand out from the crowd. You build stronger relationships and increase customer loyalty. This approach goes beyond simple marketing. You create real value for every person who shops with you.

Sustainability

Waste Reduction

You want your business to run cleaner and greener. AI makes this possible in ways you might not expect. It helps you spot waste before it happens and gives you tools to fix it fast. You can see the difference in your bottom line and in the world around you.

AI checks materials for defects using computer vision. It finds problems early, so you waste less. You also get smarter manufacturing. AI predicts what will go wrong and helps you avoid mistakes. This means you use fewer raw materials and throw away less.

AI also helps you save energy. It manages power use in your factories, cutting costs by up to 15% and lowering carbon emissions by 10%. You get more from every pound you spend on energy.

You can keep your machines running longer, too. AI predicts when equipment will break down. You fix things before they fail, so you lose less time and fewer materials.

Managing stock gets easier with AI. It forecasts demand and tracks inventory, so you do not over-order or let goods expire. You keep your shelves full but not overflowing.

AI even helps you join the circular economy. It finds ways to recycle and reuse materials. You turn waste into new products and open up new ways to earn money.

AI inspects materials for defects, reducing scrap.

It manages energy use, cutting costs and emissions.

Predictive maintenance keeps machines running and saves resources.

Smarter inventory means less overstock and fewer expired goods.

AI finds recycling opportunities, supporting a circular economy.

Some companies use AI-powered robots to sort recycling. For example, AMP Robotics built robots that sort materials with 99% accuracy. This boosts recycling rates and keeps more waste out of landfills.

Tip: Every bit of waste you cut saves money and helps the planet. AI gives you the tools to do both.

Ethical Sourcing

You want to know your products come from the right places. AI helps you make sure your supply chain is fair and safe. It watches every step, so you can trust your partners and suppliers.

AI checks if your suppliers follow labour laws and protect the environment. It uses machine learning to spot anything unusual, like signs of child labour or unsafe working conditions. You get alerts if something looks wrong, so you can act quickly.

You can also track your goods in real time. AI and blockchain work together to show you where every product comes from. You see the whole journey, from raw material to finished item. This makes it easier to prove your business meets high ethical standards.

AI monitors for labour law and environmental compliance.

Machine learning spots signs of unethical practices.

Blockchain and AI together verify sourcing at every step.

You build trust with your customers when you show them your products are made the right way. AI helps you keep your promises and protect your brand.

Note: Ethical sourcing is not just good for business. It is the right thing to do. AI makes it easier for you to lead the way.

Private Labelling Advantage

Private labelling gives you the power to build your own brand, even if you do not own a factory. With AI-driven supply chains, you can stand out in the market, control quality, and grow trust with your customers. Let’s see how you can use these tools to your advantage.

Custom Branding

Logo & Packaging

You want your products to look unique and feel special. AI makes this easy. You can design your logo and packaging quickly, test new ideas, and see what works best for your audience. AI tools help you create packaging that grabs attention and matches your brand style.

AI lets you test packaging designs fast. You can see what your customers like before you order large batches.

You can choose eco-friendly materials. AI suggests options that cut waste and help the planet.

Personalised packaging is possible. AI uses customer data to create designs that speak to different groups.

Smart packaging, like temperature-sensitive labels, keeps products safe and adds a fun touch for buyers.

AI predicts how much packaging you need, so you never run out or overstock.

Tradepak uses AI to turn your ideas into real designs. You give your preferences, AI suggests options, and you pick the best one. This saves time and helps you launch new products faster.

Manufacturer Links

Quality Control

You want every product to meet your standards. AI helps you keep an eye on quality at every step. It checks products using cameras and smart software, spotting problems that people might miss.

It analyses product images in real time, making checks faster and more accurate.

Electronics makers use AI to make sure every part meets strict rules. This means better products and less waste.

With AI, you can trust that your products will look good and work well. You avoid costly returns and keep your customers happy.

Brand Growth

Trust & Recognition

You want your brand to grow and earn trust. AI helps you manage your supply chain, so you always have the right products in stock. It also helps you understand what your customers want.

AI improves inventory management and demand forecasting. You avoid running out of popular items.

AI can cut errors in demand forecasts by up to 50%. This means you make better decisions and keep shelves stocked.

Big names like Walmart and Amazon use AI to study what shoppers do. This helps them build trust and make smart choices.

When you use AI for private labelling, you build a brand that people remember. You deliver on your promises, and your customers come back for more.

You have learned how an AI Supply Chain helps you control everything. It makes your business stronger and more flexible. You get many benefits:

Your business runs greener with less waste and less fuel.

You can spot risks early and see what is happening now.

Full automation helps you make quick and smart choices.

Data moves easily because AI and IoT work together.

If you want to be a top dropshipper, Tangbuy’s private labelling helps you stand out:

Advantage | Description |

|---|---|

Unique Brand Identity | Make a brand that is easy to notice. |

Control Over Product Appearance | Change how products look and pack them for better recognition. |

Adaptability to Market Trends | Change products fast when trends shift. |

Customer Trust | Build loyalty with special products. |

Supply Chain Efficiency |

Now is the best time to make your supply chain smarter, greener, and ready for what comes next.

FAQ

What is an AI-driven supply chain platform?

You use an AI-driven supply chain platform to connect sourcing, manufacturing, and delivery in one place. It helps you make decisions faster, cut costs, and spot problems early.

How does AI help with supplier selection?

AI checks supplier data, ranks performance, and gives you clear choices. You save time and avoid mistakes. You always know which supplier fits your needs best.

Can AI really predict demand accurately?

Yes, AI uses sales data, trends, and even weather to predict what you need. You get better forecasts, so you avoid running out or overstocking.

Will AI reduce jobs in my supply chain?

AI takes care of boring, repetitive tasks. You and your team can focus on important work, like solving problems and helping customers. It helps you do more, not less.

How does AI improve delivery times?

AI finds the best routes, checks traffic, and plans deliveries. You get parcels to customers faster and save money on fuel. Your service becomes more reliable.

Is it hard to start using an AI supply chain platform?

You do not need to be a tech expert. Most platforms guide you step by step. You can start small and add more features as you grow.

Can AI help my business become more sustainable?

Absolutely! AI helps you cut waste, use less energy, and choose ethical suppliers. You make greener choices and show customers you care about the planet.

TangBuy: A Smarter Way to Dropship in 2025

If you're looking to stay competitive with dropshipping in 2025, speed and trend-awareness are key. TangBuy helps you stay ahead with real-time product trends, fast fulfilment, and factory-direct sourcing. With over 1 million ready-to-ship items, 24-hour order processing, and seamless Shopify integration, TangBuy makes it easier to test, scale, and succeed in today's fast-moving eCommerce landscape.

See Also

Five Effective Methods to Source Dental Goods Online in 2025

Five Innovative Approaches to Find Trending Products Online

Comparing Amazon and eBay: Best Platform for Sellers in 2025

Choosing Between Amazon and eBay for Your Online Store in 2025

Comprehensive Guide to Starting Your Dropshipping Venture in 2025