Top Communication Mistakes with Suppliers and How to Avoid Them

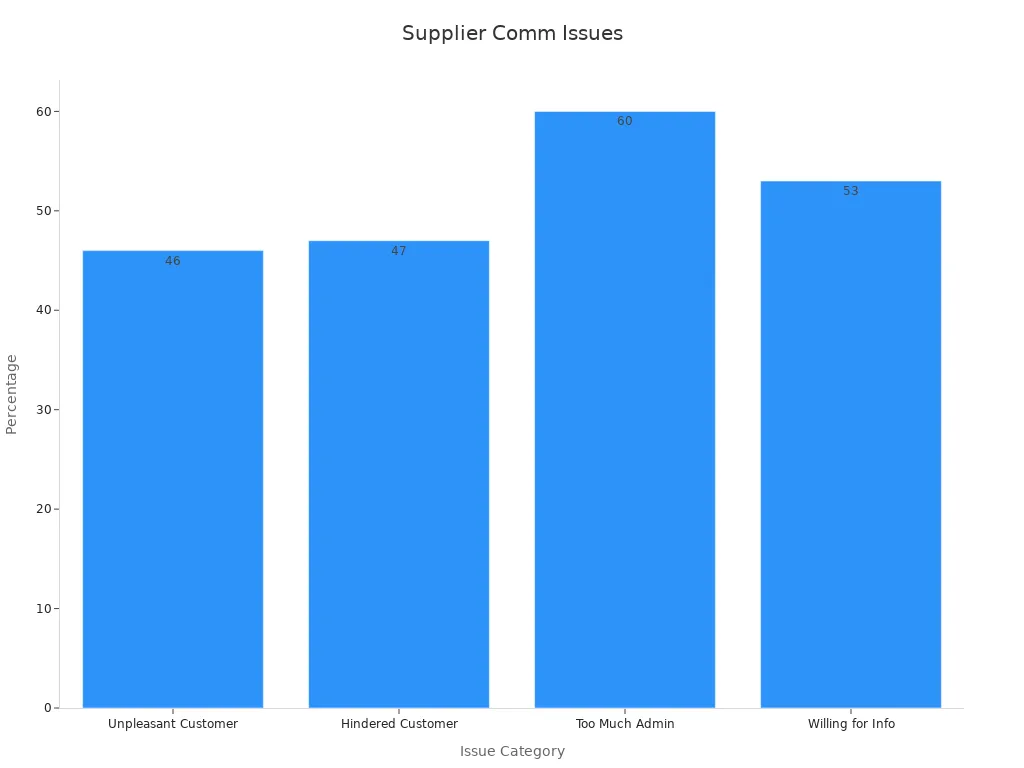

You know that communication problems with suppliers can be tough to manage. These communication problems happen frequently and can slow down your business or reduce your profits. Here are some numbers that highlight these issues:

Statistic Description | Percentage |

|---|---|

Suppliers who find their most important customer unpleasant | 46% |

Suppliers who feel hindered by their key customer | 47% |

Suppliers who agree customers expect too much admin work | 60% |

Suppliers willing to provide more information if easier to work with | 53% |

By addressing communication problems and talking clearly and often, you can support your suppliers better. This improves your team’s efficiency and speed. Teams equipped with good tools communicate three times better. As you read, consider how you currently handle communication problems with your suppliers.

Key Takeaways

Give clear and detailed messages when you order. This helps stop mistakes and delays. Answer supplier questions fast to keep projects on time. Pick one main way to talk so all messages stay organized. Know that people may have different cultures or languages. Use simple words and make sure everyone understands. Set clear deadlines and make sure everyone follows them. This builds trust and stops problems.

Common Communication Problems

Unclear Requirements

Sometimes you think you told your supplier everything. But your message might not be clear. Unclear requirements are a big problem. For example, you may ask for “high quality” materials. Your supplier might not know what that means for you. This can cause mistakes or delays. You might even get the wrong products.

Tip: Use simple templates or checklists when you order. Write down every detail, like size, color, and delivery date. This helps your supplier know what you want.

Misunderstandings happen when you do not give enough information. If you forget to tell your supplier about a change, they might send the wrong things. Small mistakes can turn into big problems. You could lose sales or have unhappy customers.

Delayed Feedback

If you wait too long to answer your supplier, things slow down. Delayed feedback is a big reason for communication problems. Imagine your supplier asks you to approve a sample. If you take days to reply, production and delivery get pushed back.

Supplier performance metrics, like on-time delivery and order accuracy, show why quick feedback matters. If you do not answer fast, your supplier cannot meet deadlines. One French furniture company had problems when suppliers were late. They had to store items longer and pay more money. Delayed data also makes it hard to make good choices. This can cause stockouts or extra costs.

Note: Set clear times for feedback. Tell your supplier when you will reply. This helps everyone stay on track and avoid last-minute problems.

Overuse of Email

Email is easy to use, but too many emails can cause trouble. Important messages can get lost. People might miss key details. Using email too much is a common problem. It can lead to confusion and mistakes.

You might send an order update, but your supplier does not see it in a busy inbox.

You may forget to copy the right people, so some do not know what is going on.

Try using one main tool for all your messages, like a shared chat or project board. This keeps everything together and makes it easy to find important information.

Cultural and Language Barriers

Misunderstandings

You may think your message is clear to everyone. But people from other cultures might see it differently. Words or actions can mean something else in another country. For example, giving direct feedback might seem helpful to you. But someone from a culture that likes harmony could think it is rude. Even large companies have had these problems. Here are some real examples:

Cultural Misunderstanding Example | Description | Measurable Impact on Supplier Communications |

|---|---|---|

PepsiCo in China | Slogan mistranslation "Pepsi brings you back to life" was rendered as "Pepsi brings your ancestors back from the grave" | Caused brand confusion and potential loss of consumer trust, illustrating language and cultural misinterpretation risks |

German-Indian Negotiations | German direct communication perceived as aggressive; Indian indirect style seen as evasive | Led to negotiation misunderstandings, strained supplier relations, and delayed agreements |

Swedish-Thai Feedback | Swedish candid feedback perceived as rude by Thai counterparts valuing harmony | Led to damaged relationships and reduced openness in supplier communications |

You can stop these problems by using simple words. Do not use slang or sayings. If you work with people from other cultures, try cultural training for your team. This helps everyone know what to expect and how to act.

Tip: Ask your supplier to say back the main points. This makes sure they understand and helps avoid mistakes.

Time Zone Challenges

When you work with suppliers in other countries, time zones can be hard. Projects can slow down and people can get confused. Sometimes, you send a message and wait a long time for an answer. A Harvard Business School study found that losing just one or two shared business hours can cut communication by over 9%. You may have fewer calls, meetings, and messages. This can hurt teamwork and slow decisions.

Here are some problems time zones can cause:

Deadlines missed because answers come late

People get confused about meeting times

To help with these problems, use digital tools that show updates right away. Set clear times for meetings and deadlines. Try to have some work hours that overlap. Being patient and planning ahead helps keep your projects moving.

Lack of Accountability

When you work with suppliers, you must set clear rules. You also need to set goals. If you skip this, you can have big problems. Lack of accountability can break trust. It can also hurt your business. Both sides should know what to expect. They should know what happens if someone makes a mistake.

Missed Deadlines

Missed deadlines can slow down your supply chain. If your supplier is late, your customers might get upset. Studies show 47% of supplier partnerships fail. Eight out of ten companies have seen supplier relationships break. These failures often start with missed deadlines. They can also start with unfair practices or unclear rules. If you do not hold each other accountable, small problems can grow. They can turn into bigger Communication Problems.

Tip: Set clear deadlines and write them down. Use simple contracts or agreements. Review these dates together so everyone remembers.

You can also check in often to talk about progress. If someone misses a deadline, talk about why it happened. Then talk about how to fix it next time.

Poor Responsiveness

If you or your supplier take too long to reply, things can go wrong. Poor responsiveness causes confusion, delays, and mistakes. You can measure how well your supplier responds by looking at key numbers. Here are some important ones:

KPI Name | What It Measures | Why It Matters |

|---|---|---|

How fast your supplier answers questions | Fast replies keep projects moving | |

On-Time Delivery Rate | Orders delivered on or before the due date | Timely delivery keeps your customers happy |

Lead Time | Time from order to delivery | Shorter times mean more flexibility |

Delivery Accuracy | Orders that match what you asked for | Fewer mistakes save time and money |

Defect Rate | Number of bad or broken items | High quality means fewer returns and less waste |

You can use these numbers to find problems early. Try using a scorecard or a simple chart to track your supplier. Share this information openly. When you talk about results, you help each other get better.

Note: Regular reviews and open sharing build trust. They also help you fix problems before they get worse.

Ineffective Communication Tools

Disorganized Records

A quick call or text might seem enough to keep things moving. But if you use only calls or scattered emails, you can lose important details. You might forget what you promised. Your supplier could miss a change you told them. This causes confusion and Communication Problems. Your business can slow down.

Here are some real risks of poor recordkeeping:

The SEC fined 16 companies $81 million for not saving business messages sent on apps like WhatsApp and Discord.

Senior managers sent important messages that were never saved, so it was hard to know what was agreed.

When records are lost or changed, people can misunderstand what really happened.

Companies that told about their mistakes got smaller fines, showing these problems are serious.

You can avoid these problems by using one main tool for all supplier messages. Try a shared platform to store orders, updates, and agreements in one place. This makes it easy to find what you need. Everyone can stay on the same page.

Security Concerns

If you use too many tools or unsafe ways to talk, your business is at risk. Hackers look for weak spots in your communication. If you share private information by email or text, someone could steal it. This can hurt your brand and cost you money.

Check out these numbers about security risks with suppliers:

Statistic Description | Data Point |

|---|---|

Organizations with at least one breached third-party vendor | |

Third-party vendors analyzed | Over 73,000 |

Poor security in third-party vendors vs. primary organizations | 5x more likely |

Vendors from 10 or more countries | 14% |

You can see how fast the risk grows when you work with many suppliers. If you use secure, central tools, you protect your business and your partners. Better tools help your team work faster and make fewer mistakes. When you keep records safe and easy to find, you fix Communication Problems before they start.

You can build stronger supplier relationships when you keep your messages clear, quick, and easy to find. Proactive steps like regular check-ins, shared digital platforms, and open feedback help you solve issues faster. Here’s a quick list to guide you:

Use one main tool for updates and orders.

Set clear deadlines and reply on time.

Schedule regular check-ins with your suppliers.

Keep your language simple and direct.

Stay open and consistent. You will see fewer mistakes and smoother teamwork.

FAQ

What is the best way to keep track of supplier conversations?

You should use one main tool, like a shared platform or project board. This keeps all your messages, orders, and updates in one place. You can find what you need fast and avoid confusion.

How can I make sure my supplier understands my requirements?

Write down every detail. Use simple words and avoid slang. Ask your supplier to repeat the main points back to you. This helps you catch mistakes before they happen.

What should I do if my supplier often replies late?

Set clear response times from the start. Let your supplier know when you expect answers. You can also schedule regular check-ins to keep things moving.

How do I handle language or cultural differences with suppliers?

Tip: Try cultural training for your team. Use clear, simple language. Avoid jokes or sayings that might confuse others. If you are not sure, ask your supplier to explain what they understood.

TangBuy: A Smarter Way to Dropship in 2025

If you're looking to stay competitive with dropshipping in 2025, speed and trend-awareness are key. TangBuy helps you stay ahead with real-time product trends, fast fulfilment, and factory-direct sourcing. With over 1 million ready-to-ship items, 24-hour order processing, and seamless Shopify integration, TangBuy makes it easier to test, scale, and succeed in today's fast-moving eCommerce landscape.

See Also

Ways To Find Wholesale Products With High Profit Margins

Selecting Trustworthy Wholesale Vendors For Affordable Bulk Shoes

Understanding The Real Expenses Of Dropshipping In 2025