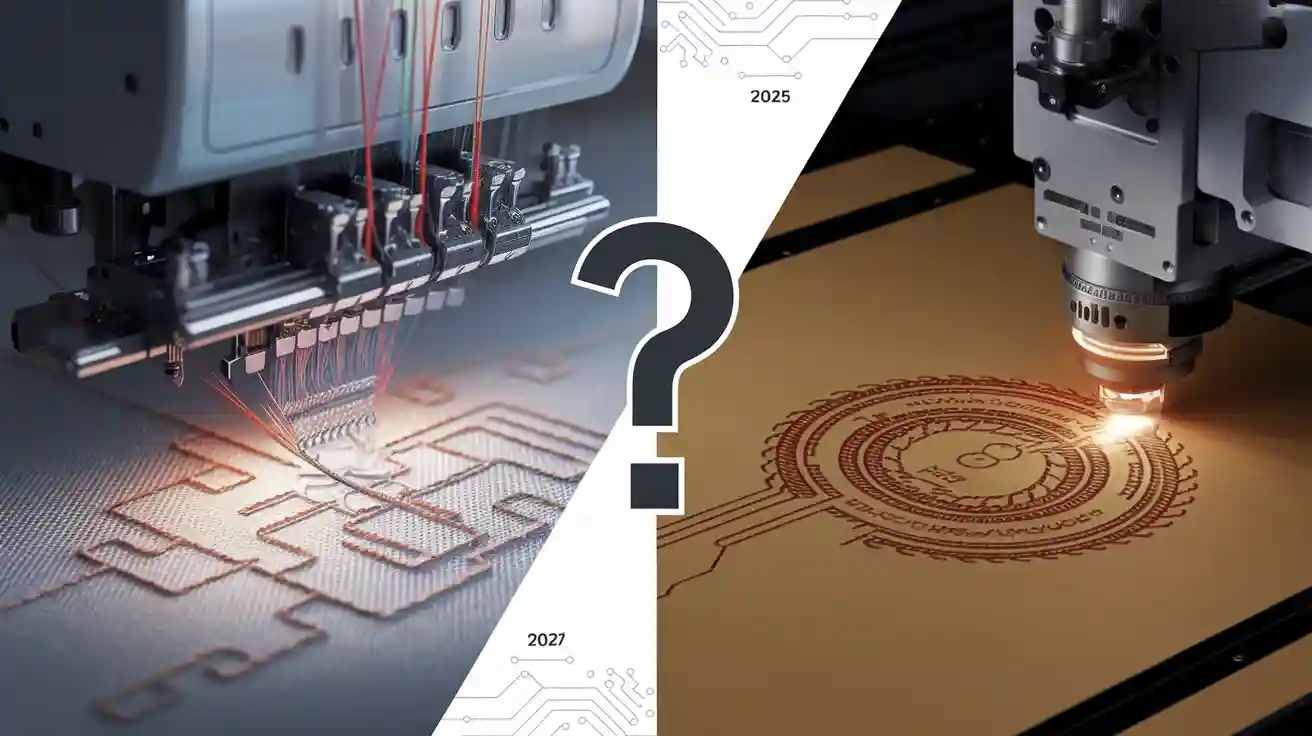

Computer Embroidery vs Laser Engraving Which Technique Stands Out in 2025

Comparing Techniques for 2025

Explore the strengths of embroidery and engraving in 2025.

Features | Computer Embroidery | Laser Engraving |

|---|---|---|

Main Use | Fabrics, textiles | Hard surfaces, mixed media |

Process | Stitching with threads | Etching with laser |

Typical Products | Apparel, patches, bags | Awards, gadgets, décor |

Precision | Good for bold shapes | Excellent for tiny lines |

Durability | Lasts well on fabric | Permanent on hard materials |

Speed | Slower, depends on design | Fast, instant marking |

Cost | Lower per unit cost | |

Flexibility | Limited to textiles | Works on many materials |

Consistency | Good but may vary | Highly consistent results |

In 2025, laser engraving is great for businesses that want fast work, accuracy, and many uses. The market for engraving machines is growing quickly. Experts think it will be worth $7.79 billion by 2034. People want more personalisation, so both Computer Embroidery and engraving are popular. But smart technology and being eco-friendly make laser engraving even better.

Precision

Materials

Durability

Speed

Cost

Business impact

These things help you look at both methods. You can then pick what works best for you.

Key Takeaways

Laser engraving is fast and very accurate. It is good for businesses that need things done quickly.

Computer embroidery gives a classic and textured look. It is great for fabric items like uniforms and gifts.

Laser engraving is best for detailed designs with sharp lines. Embroidery works well for bold shapes.

Both methods let you personalise items. Laser engraving can be used on more materials, like wood and metal.

Think about setup costs. Laser engraving usually costs less to start than computer embroidery, especially for hard designs.

Laser engraving lasts longer. The design becomes part of the material, so it does not fade or peel.

You can use both techniques together. This makes special products with the feel of embroidery and the smooth look of engraving.

Watch market trends. People want personalised items, and both methods help your brand get noticed.

Overview

Computer Embroidery

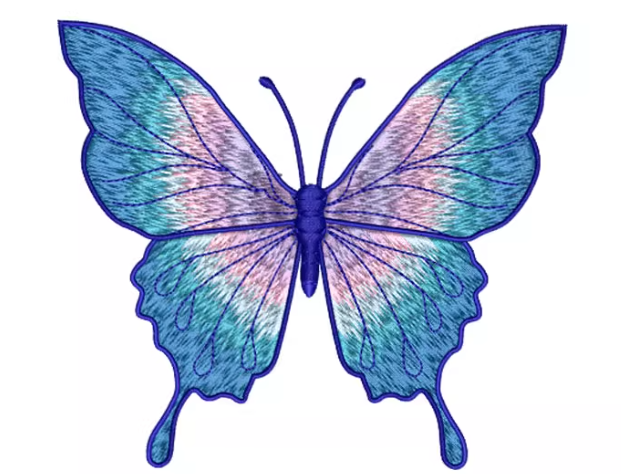

You may have seen bright logos or names sewn onto shirts, hats, or bags. This is Computer Embroidery. It uses a machine that is controlled by a computer. The machine sews patterns, words, or pictures onto fabric. You upload your design and pick thread colours. The machine does the sewing for you. The work is tidy and exact. The designs are raised and you can feel them. They stand out on clothes and other fabric.

Here is what happens:

You pick your design and fabric.

The machine reads your digital file.

It sews the pattern with different threads.

People use Computer Embroidery for uniforms, sports kits, and gifts. You can put a company logo on polo shirts. You can make custom patches for jackets. The finished items look smart and last after many washes.

Tip: If you want a bumpy, colourful look on fabric, Computer Embroidery gives you a classic style.

Laser Engraving

Laser Engraving is not the same. It uses a strong laser beam to mark or cut a surface. You do not need thread or needles. The laser burns or etches the top layer of the material. You upload your design and set up the machine. The laser makes sharp and clear pictures.

Here is what happens:

You choose your material, like wood, metal, glass, or acrylic.

The machine follows your digital design.

The laser engraves the pattern very neatly.

Laser Engraving is used for trophies, signs, phone cases, and jewellery. You can add names, logos, or fancy art to many things. The finish is smooth and stays forever. It does not fade or peel.

Feature | Computer Embroidery | Laser Engraving |

|---|---|---|

Main Use | Fabrics, textiles | Hard surfaces, mixed media |

Process | Stitching with threads | Etching with laser |

Typical Products | Apparel, patches, bags | Awards, gadgets, décor |

Note: If you want neat detail on hard materials, Laser Engraving gives you lots of choices.

Both methods let you make products special, but they work best for different things. Computer Embroidery gives you a soft, bumpy finish. Laser Engraving gives you a smooth, lasting mark. Think about your item and the style you want before you decide.

Precision

Detail Level

When you want your design to stand out, detail is important. You may wonder which method gives sharper lines or smaller patterns. Laser engraving is best for tiny details. The laser beam is very thin and makes crisp edges. It can do small text and complex shapes. You can even engrave a photo on wood or metal and see every line. If your logo has many small parts, laser engraving keeps it neat and clear.

Computer Embroidery works in another way. The machine uses threads to make your design. This gives a raised and bumpy finish. The thickness of the thread limits how small you can go. If your logo has thin lines or tiny letters, embroidery may look fuzzy or thick. You can still get good detail with new machines, but it works best for bold shapes and simple words. Embroidery looks great on sports kits or uniforms where you want the design to stand out.

Here is a quick comparison:

Feature | Computer Embroidery | Laser Engraving |

|---|---|---|

Fine Detail | Good for bold shapes | Excellent for tiny lines |

Texture | Raised, tactile | Smooth, flat |

Colour Options | Many thread colours | Usually single colour |

Tip: If you want lots of colour and a 3D look, Computer Embroidery gives you a classic style. For sharp, tiny details, laser engraving is the best choice.

Consistency

You want every item to look the same, especially for business. Consistency is important for your brand. Laser engraving gives almost perfect results each time. The machine follows your digital file exactly. You can engrave hundreds of items and they all match. There is no risk of thread breaking or colours changing.

Computer Embroidery also gives good consistency. The machine repeats your design on each item. You might see small changes if the fabric moves or the thread is too tight or loose. New embroidery machines help stop these problems, but you still need to check each batch. If you use good machines and threads, you get reliable results.

Let’s break it down:

Laser engraving:

Matches every piece

No colour changes

Works on many materials

Computer Embroidery:

Consistent on fabric

Small changes possible

Best for textiles

Note: If you need many identical products, laser engraving is easy. If you want a classic look on fabric, Computer Embroidery is still a good choice.

Materials

Computer Embroidery Materials

You might ask what fabrics and threads work with Computer Embroidery. This method is best for textiles. You often see it on cotton shirts, polyester jackets, and linen bags. The machine uses different threads to stitch your design. Each thread type looks and feels different. Some are strong, while others are shiny or soft. Here’s a table to show your choices:

Thread Type | Durability | Sheen/Appearance | Fabric Compatibility |

|---|---|---|---|

Cotton | Strong but makes lint; not as tough as polyester. | Matte look, good for old-fashioned styles. | Works well with cotton and linen. |

Metallic | Fragile and can break; best for small details. | Shiny and sparkly, great for decoration. | Not good for things you wash a lot. |

Polyester | Very strong and hard to break; good for heavy use. | Shiny finish, bright colours. | Best for poly-cotton and tough fabrics. |

Rayon (Viscose) | Softer and not as strong; good for decoration. | Very shiny, soft like silk. | Great for soft fabrics and detailed designs. |

You have many thread options, but you must match them to your fabric. Polyester threads are good for sports clothes. Cotton threads fit classic shirts. Metallic threads make things sparkle, but use them for special parts only. Computer Embroidery gives a raised feel, but it works best on fabric. If you want to decorate wood or glass, you need a different method.

Tip: Always check your fabric before you start. Some threads look better on certain materials.

Laser Engraving Materials

Laser engraving lets you use many different surfaces. It is not just for textiles. The laser can mark or cut lots of materials. Here is a list of what you can engrave:

Metals (Copper, Gold, Silver, Aluminium, Alloy, Iron, Brass, Steel)

Wood

Stone

Glass

Acrylic

Plastic

Rubber

Leather

Fabric

Textile

Paper

You can make wooden gifts special, put logos on metal gadgets, or add names to glass trophies. Laser engraving works on hard and soft things. You get sharp detail and a finish that lasts. If you want to make things that are not clothes, laser engraving gives you more choices.

Note: Laser engraving lets you change materials fast. You do not need to swap threads or needles.

Flexibility

When you look at Computer Embroidery and laser engraving, flexibility is important. Laser engraving works with many materials. You can change patterns and designs quickly. The machine gives clear pictures and sharp lines every time. Computer Embroidery is mainly for textiles. You get a raised, colourful look, but you must use fabric.

Here is a table to show the difference:

Feature | Laser Engraving | Computer Embroidery |

|---|---|---|

Material Compatibility | Works with many types of materials | Only works with some materials |

Precision | Very precise | May not show tiny details |

Processing Speed | Fast | Slower because it stitches |

Design Versatility | Many design choices | Not as flexible as laser engraving |

Laser engraving gives you more freedom. You can put a logo on a metal pen, then work on a wooden box. Computer Embroidery is great for uniforms, patches, and branded clothes. If you want to make things for many jobs, laser engraving is the flexible choice.

Callout: If you need to use lots of materials and want quick results, laser engraving is best. If you want a classic, bumpy look on fabric, Computer Embroidery is the right pick.

Durability

Embroidery Wear

If you pick computer embroidery, you want it to last. You might ask if the stitched names or logos stay nice after lots of use. Embroidery makes a raised pattern with threads. This feels strong and looks bright. If you choose good fabric and thread, your embroidered things can handle many washes and daily use.

Researchers have checked how embroidery changes fabric strength. Here are some results:

Study | Findings |

|---|---|

Pant and Rao (2015) | Embroidery makes fabric harder to tear. Chain stitch is strongest. Herringbone stitch is weakest. |

Manal et al. (2012) | Satin, couching, and crossed back stitches make fabric stiffer and stronger, especially with thick stitching. |

So, if you use chain stitch or thick patterns, your shirt or bag will not tear or stretch easily. The product feels tough and keeps its shape. Embroidery also helps protect the fabric, so the edges do not fray as much.

But you must think about where you use your item. Embroidered designs on cotton or twill can fade if you wash them with strong soap or leave them in the sun for too long. Metallic threads look nice, but they are best for special days, not for every day. For regular use, polyester threads and strong fabrics are best.

Tip: Wash embroidered things inside out and use gentle cycles. This keeps the colours bright and the stitches tight.

Engraving Longevity

Laser engraving is even tougher. The design becomes part of the material, not just on top. The laser burns or etches your logo, name, or art into leather, acrylic, wood, or metal. This means the mark will not peel, fade, or wash away.

Here is why laser-engraved things last:

Leather and acrylic items look fancy and last longer than most fabrics.

The design is part of the surface, so it does not get ruined by water, heat, or rubbing.

You can use laser-engraved things outside or in hard places without worry.

If you need something for work or outside, laser engraving is best. You can leave a metal sign in the rain or use a laser-engraved keyring every day, and the design stays clear. Embroidery gives a classic, bumpy feel, but laser engraving lasts the longest.

Note: If you want your logo to last for years, laser engraving is the safest choice. You do not need to worry about fading, peeling, or damage.

Speed

Embroidery Workflow

When you want to personalise shirts, hats, or bags, you probably wonder how long it takes. Computer embroidery uses machines that stitch your design onto fabric. You upload your pattern, choose your threads, and let the machine do the work. The speed depends on the type of embroidery and the complexity of your design.

Here’s what you can expect:

Flat embroidery machines reach up to 1,500 stitches per minute (SPM). That’s quick for simple logos or names.

Cap embroidery runs slower, between 300 and 1,200 SPM. Curved surfaces need more care.

Most jobs start at 300 SPM. If you want lots of colour changes or thick stitching, the machine slows down.

You might find that a batch of shirts with basic logos finishes in a few hours. Detailed designs with many colours take longer. The machine needs to switch threads and adjust for each part. If you order hundreds of pieces, you wait longer. Embroidery works best for small to medium batches. You get a classic look, but you need patience for big orders.

Tip: If you want a raised, colourful logo on fabric, embroidery gives you a smart finish. Plan extra time for large batches or complex designs.

Engraving Efficiency

Laser engraving changes the game when you need speed. The machine uses a focused beam to mark or cut your design. You upload your artwork, set the material, and start the process. The laser moves fast and does not need to switch threads or colours.

Here’s why laser engraving stands out:

The laser works on many materials without stopping. You can engrave wood, metal, acrylic, or glass in minutes.

The process is almost instant for simple designs. You get sharp lines and clear details every time.

Large volumes are easy. The machine repeats your design on hundreds of items with no drop in quality.

If you run a business and need quick turnaround, laser engraving saves you time. You can finish big orders in a day. The machine does not slow down for colour changes or thick patterns. You get consistent results, whether you make ten or a thousand pieces.

Feature | Computer Embroidery | Laser Engraving |

|---|---|---|

Speed (per minute) | 300–1,500 SPM | Fast, instant marking |

Batch Handling | Best for small/medium runs | Excellent for large runs |

Turnaround Time | Hours to days | Minutes to hours |

Note: If you want to handle large orders with tight deadlines, laser engraving gives you the edge. You save time and keep your quality high.

Laser engraving suits businesses that need speed and flexibility. Computer embroidery works well for special, textured designs but takes longer. Think about your order size and deadline before you choose.

Cost

Setup Costs

When you start a new project, you want to know how much it will cost to get going. Computer embroidery and laser engraving both need machines and a bit of preparation before you can begin. You pay a setup fee for each method, which covers things like getting your design ready and setting up the equipment.

Laser engraving usually has a lower setup cost than computer embroidery. You might pay around $55.00 to set up a laser engraving job. For embroidery, the setup cost is about $80.00. If your design is very detailed or uses lots of stitches, embroidery may need an extra setup charge. This can be $40.00 more if your design goes over 8,000 stitches.

Tip: If you want to keep your starting costs low, laser engraving is often the better choice.

Per-Unit Cost

Once you have paid the setup fee, you need to think about how much each item will cost to make. This is called the per-unit cost. It tells you how much you spend for every shirt, trophy, or gadget you produce.

Here’s a table to help you compare:

Method | Setup Cost | Running Cost (per unit) |

|---|---|---|

Embroidery | $80.00 | $5.95 |

Additional Setup | $40.00 | $0.70 (per 1k stitches above 8k) |

Laser Engraving | $55.00 | $3.50 |

Laser engraving gives you a lower running cost per item. You pay about $3.50 for each engraved piece. Computer embroidery costs about $5.95 per item. If your embroidery design is very complex, you pay a bit more for every extra 1,000 stitches. For small orders, the difference might not seem big. If you plan to make hundreds or thousands of items, laser engraving helps you save more money.

Note: Laser engraving is great for large orders. You get a lower cost per item and finish jobs quickly.

Profitability

You want your business to make money, so you need to look at what affects your profit. Laser engraving can be very profitable, especially if you work with manufacturers who need regular marking on parts. You get steady jobs and a reliable income. The demand for personalised products is rising, so you have more chances to grow your business.

For both methods, you need to think about a few things:

Minimum charge to cover your setup time.

Artwork charge for creating logos or designs.

Materials cost for all your supplies.

Time needed to finish each piece.

If you choose computer embroidery, pick the right machine for your market. Make sure you have a good power source and enough space to work. You need quality threads and a place to store finished products. These steps help you keep your costs down and your profits up.

Laser engraving lets you use your creativity. You can offer personalised gifts, industrial marking, or branded items. Careful planning and smart choices help you make the most of this growing market.

Callout: If you want to boost your profits, look for steady jobs and keep your costs low. Laser engraving often gives you more flexibility and a faster way to grow your business.

Applications

Branding

Branding means making your logo stand out. You want your logo to look neat and last a long time. It should feel special too. Computer Embroidery and laser engraving both make strong logos. Embroidery gives a raised logo on fabric. This is good for uniforms, hats, and bags. People think embroidered logos show quality.

Laser engraving makes a sharp mark on hard things. You can put your logo on metal, glass, wood, or acrylic. This looks modern and smooth. It is great for awards, gadgets, and drinkware. If you want your brand to look fancy, laser engraving is a good choice.

Here is a table that shows how branding methods compare:

Technique | Strengths | Weaknesses |

|---|---|---|

Pad Printing | Cheap, works on many things | Not very strong |

Screen Printing | Clear designs, saves money | Hard for tricky images |

Laser Engraving | Looks expensive, lasts long | Costs more |

Embroidery | Lasts long, looks nice | Only for fabric |

Digital Printing | Good for colourful, detailed designs | Hard to match colours |

If you want a logo that lasts and looks fancy, use embroidery or laser engraving. Pick embroidery for clothes and laser engraving for hard items.

Product Types

You can personalise many things. Computer Embroidery works best on clothes and fabric items. Think of polo shirts, jackets, caps, and tote bags. You get a soft finish that people can see and touch.

Laser engraving lets you do even more. You can mark mugs and bottles. Kitchen tools like cutting boards and spoons look cool with engraved names. Wine glasses, barware, and metal tools can show your brand. Laser engraving works on glass, acrylic, anodised aluminium, and coated things.

Here is a table to help you pick the right method:

Product Type | Description |

|---|---|

Custom drinkware | Personalise mugs, tumblers, and bottles |

Kitchen and dining accessories | Engrave cutting boards, utensils, and trays |

Promotional items | Brand giveaways and event merchandise |

Wine glasses and barware | Add fancy designs and names |

Branding metal parts and tools | Mark tools and hardware with logos or text |

Materials for laser engraving | Glass, acrylic, anodised aluminium, coated surfaces |

Use embroidery for fabric things. For other items, laser engraving gives you more choices and a modern style.

Combining Techniques

You might ask if you can use both methods together. Yes, you can, and more people do this now. Mixing Computer Embroidery and laser engraving gives you the best results. You can put a raised logo on a bag and engrave a metal tag too. This makes products look special and expensive.

Mixing both methods has many good points:

You can make cooler designs.

You get neat work and fast results.

You can use lots of materials.

But you must pick your materials carefully. Some fabrics do not work with engraving. The machines can cost a lot. Still, if you want to be different, this way helps you offer something new.

Challenges of Combining Technologies | |

|---|---|

More design choices | Some fabrics may not work |

Neat work and fast results | Machines can be expensive |

Works with many materials | Must pick materials carefully |

If you want to wow your customers, try using both embroidery and engraving. You can make products that look and feel special.

You also get more ways to be creative. Laser engraving can burn the top of fabric for an old look, like on denim or leather. Embroidery adds texture and makes designs stand out. When you use both, you get raised effects and fine details that last.

Business Impact

Market Trends

Lots of people want things that feel special and unique. This makes businesses change how they use computer embroidery and laser engraving. Companies now offer custom names, logos, or designs on shirts and gadgets. Laser engraving is growing quickly because it works on many materials. It also gives clear and sharp results. Experts think laser engraving could be worth about $432 million by 2030. That is a big increase!

Laser machines are getting smarter. They use AI and automation to work faster and more accurately. You can finish big orders quickly and keep each item looking great. Computer embroidery also gets better with new technology. But laser engraving is faster and more flexible. If you run a business, customers want quick service and perfect detail. These changes make both methods improve. Laser engraving is leading in many industries.

Tip: To keep up with changes, offer personalisation and fast service. Customers like products made just for them.

Customer Perception

How do people feel about computer embroidery and laser engraving? Here is a simple table:

Feature | Laser Engraving | Embroidery |

|---|---|---|

Quality | Very precise, looks premium | Looks high quality and neat |

Durability | Lasts a long time | Decoration stays on |

Design Complexity | Only one colour, no shading | Can use many colours and complex designs |

Typical Use | Used on fancy metal items | Used on nice clothes and bags |

Laser engraving looks modern and fancy. People think it is high-tech and good for gifts. The marks last and look sharp on metal, glass, or wood. Embroidery looks classic and neat. Customers think embroidered logos show care and quality. You can use lots of colours and make bold designs. Both ways impress people, but in different styles.

Note: If you want your brand to look smart and modern, pick laser engraving. For a cosy, classic feel, embroidery is best.

Environmental Factors

You may wonder which method is kinder to the planet. Laser engraving uses less water and fewer chemicals than printing. It is clean and does not make much waste. You can engrave recycled things or use eco-friendly materials like bamboo or glass. This helps your business look green and responsible.

Computer embroidery is also getting better for the environment. You can use threads made from recycled fibres or organic cotton. New machines use less energy and work faster, so you save resources. But embroidery still needs fabric and thread, so you must think about waste.

If you care about the planet, both methods are good choices. Laser engraving makes less waste and is cleaner. Embroidery lets you use green materials and show you care about quality.

🌱 Pick eco-friendly options to help your brand stand out and protect the planet.

Tangbuy Advantage

Private Labelling

You want your products to be different from others. Tangbuy helps you put your own brand on many items. You can use computer embroidery or laser engraving. Tangbuy makes your products look special and professional.

Here is how Tangbuy helps with private labelling:

You can use modern embroidery and engraving machines.

You can pick from lots of materials, like cotton, polyester, wood, metal, and acrylic.

You upload your logo or design, and Tangbuy does the rest for you.

Tip: If you want your brand on uniforms, gadgets, or gifts, Tangbuy’s private labelling gives you lots of choice and control.

Customisation

You want your products to show your own style. Tangbuy lets you change almost every part. You can pick colours, materials, and design details. You can choose a raised, bright logo with embroidery or a smooth, modern look with laser engraving.

Tangbuy’s customisation choices include:

Picking thread colours and stitch types for embroidery.

Choosing how deep and shiny the engraving is for hard things.

Mixing both methods for special looks.

Here is a table to help you see the customisation options:

Feature | Computer Embroidery | Laser Engraving |

|---|---|---|

Colour Options | Many thread colours | Usually single colour |

Texture | Raised, tactile | Smooth, flat |

Material Choices | Fabrics, textiles | Wood, metal, acrylic |

Design Flexibility | Bold shapes, simple text | Fine detail, complex art |

If you want to give your customers something different, Tangbuy helps you mix styles for a special result.

Brand Building

You want your brand to get bigger and better. Tangbuy helps you at every step. You can use embroidery for a classic look or laser engraving for a modern style. Tangbuy’s team works with you to make sure your logo and message look great on every item.

Here is how Tangbuy helps you build your brand:

You get advice on which method is best for your products.

You can order small amounts to try new ideas or big amounts for big events.

You get the same good quality every time, so your brand always looks good.

Note: Tangbuy does more than just make products. You get a team that wants your brand to do well.

If you want to stand out in 2025, Tangbuy gives you the help you need. You pick the method, and Tangbuy helps turn your ideas into real products.

Laser engraving is popular in 2025 because it is fast, flexible, and lasts a long time. You might like computer embroidery if you want a classic, bumpy look on fabric. If you have a business, think about what you need:

Look at what your customers want and who your rivals are.

See if paying someone else to do embroidery could save money.

Choose machines that match the jobs you offer.

Tangbuy helps you grow your brand with custom embroidery and skilled engraving. Here is what Tangbuy gives you:

Service | Description |

|---|---|

Custom Embroidery | Good logos, no minimum order, personal service |

Expert Team | New methods, high quality, strong results |

Ask the experts and pick what suits you best.

FAQ

What is the main difference between computer embroidery and laser engraving?

Computer embroidery uses threads to sew designs onto fabric. Laser engraving uses a laser to make marks or cuts on many materials. Embroidery gives a raised and colourful look. Laser engraving gives a smooth and sharp finish.

Which technique lasts longer on products?

Laser engraving usually lasts longer than embroidery. The design becomes part of the material, so it does not fade or peel. Embroidery is strong on fabric but can wear out after lots of washes.

Can I use both techniques on one product?

Yes, you can use both methods together. Many brands mix embroidery and laser engraving. For example, you can sew a logo on a bag and engrave a metal tag for a special touch.

Which method is faster for large orders?

Laser engraving is faster for big batches. The machine marks each item quickly and keeps the quality high. Embroidery takes more time, especially with complex or colourful designs.

Which is better for detailed designs?

Laser engraving is best for fine details. It can show tiny lines and even photos. Embroidery works well for bold shapes and simple text but struggles with very small details.

What materials can I use for each method?

Technique | |

|---|---|

Computer Embroidery | Fabrics, textiles |

Laser Engraving | Wood, metal, glass, acrylic, leather, some fabrics |

Tip: If you want to use many materials, laser engraving gives you more choices.

Is one method more eco-friendly?

Laser engraving uses less water and fewer chemicals. It makes less waste. Embroidery can be eco-friendly if you use recycled threads and fabrics. Both methods now offer greener options.

Which technique is more cost-effective for small businesses?

Laser engraving often costs less to set up and run, especially for big orders. Embroidery costs more for complex designs. If you want to save money and time, laser engraving is a smart choice.

TangBuy: A Smarter Way to Dropship in 2025

If you're looking to stay competitive with dropshipping in 2025, speed and trend-awareness are key. TangBuy helps you stay ahead with real-time product trends, fast fulfilment, and factory-direct sourcing. With over 1 million ready-to-ship items, 24-hour order processing, and seamless Shopify integration, TangBuy makes it easier to test, scale, and succeed in today's fast-moving eCommerce landscape.

See Also

Emerging Embroidery Trends for Custom Hats and Caps in 2025

Best Free Logo Creation Tools for Your Brand in 2025

Effective Strategies for Wholesale Bride's Earrings Dropshipping in 2025

Most Profitable Hoodie Trends for Successful Dropshipping in 2025

Choosing Between Amazon and eBay for Your Online Business in 2025