The Hidden Costs of Poor Logistics (and How AI Can Fix Them)

You may not notice them, but hidden costs in logistics can slowly take away your profits and make you slower. Poor logistics often leads to less work done, late shipments, and even safety problems. Customers see when things go wrong—they get upset and might not return. If you want to keep up and stay ahead, you should think about better solutions. Artificial intelligence can help you find problems early and make smarter decisions. Have you ever thought about how much you could save by fixing these problems right away?

Key Takeaways

Hidden costs in logistics can lower profits and slow work. Finding these costs early is very important.

Problems like overtime and transport delays can lose a lot of money. Making work smoother can help save cash.

Having too much stock uses up money and raises storage bills. Keeping the right amount of stock can free up funds.

Delivering late can hurt customer trust and lose sales. Delivering on time keeps customers happy.

Not following rules can bring big fines and hurt your reputation. Knowing the rules helps keep your business safe.

AI can watch things as they happen and predict problems. This helps businesses see issues before they get worse.

Automatic paperwork makes fewer mistakes and speeds up work. Teams can then spend more time on important jobs.

Using AI can help in the long run. It can cut costs, improve planning, and make customers more loyal.

Hidden Costs in Logistics

Operational Inefficiencies

Labour and Overtime

Sometimes your team works late or needs extra shifts. This happens when things go wrong or you do not have clear information. If you use old systems or track things by hand, staff spend more time fixing errors than moving goods. These extra hours add up quickly. Supply chain disruptions cost companies about $184 million each year. Nearly three out of four logistics managers say their jobs are harder now. If you ignore these problems, you pay more in wages and your team gets tired.

Transport and Fuel

Transport costs can slowly take away your profits. You might not notice, but firms spend over $1.04 trillion on transport. This is about 10.4% of their total revenue. If your routes are not planned well or vehicles sit unused, you waste fuel and time. Transport services make up more than 5% of GDP. If you do not track shipments as they move, you risk delays and higher costs. These hidden costs can get out of control if you do not watch them closely.

Wasted Resources

Inventory Overstock

Keeping too much stock may feel safe, but it causes problems. Overstock means you pay more for storage, security, and climate control. Your money is stuck in products instead of helping your business grow or pay debts. If items stay too long, they can become old. You might have to throw them away or sell them for less. These hidden costs are often missed until you check your finances and see the damage.

Warehouse Space

Wasted resources often come from making too much, having extra stock, and poor transport planning. These problems raise costs and make things less efficient. If you store more than needed, you pay for extra space, insurance, and inventory tax. Sometimes, you lose money on things you cannot sell. For example, too much stock means higher storage costs and risk of products going out of date. Your warehouse might be full, but you have little cash. This makes it hard to react to new chances or sudden changes in demand.

Lost Revenue

Delays and Customer Loss

Late deliveries do more than upset your customers. They can cause real money loss. Distributors lose about 12% of their revenue each year because of delays and lost customers. When customers do not get what they want on time, they may not return. You lose sales and your reputation suffers. These hidden costs can grow over time, making it harder for your business to succeed.

Missed Opportunities

You might not see the money lost from missed chances, but it is there. Fewer supplier options can stop you from getting better deals or quality. If there is not enough competition, you pay more and get less. Bad supplier choices can mean costly fixes and more delays. Missing new ideas means you do not improve or save money. Companies lose about 15-20% of sales revenue each year because of poor supplier performance. Businesses also lose around $184 million every year from supply chain disruptions. Sometimes, companies can lose up to 45% of a year’s profits from these issues. Around the world, manual supplier searches cost businesses about $20 billion. These hidden costs show up as higher spending, longer recovery, and lost chances to grow.

Tip: Watch your logistics data closely. Finding these hidden costs early helps you act before they hurt your profits.

Compliance Risks

Fines and Penalties

You might think rules are just paperwork, but ignoring them is risky. If you miss safety checks or skip steps, you can get big fines. Some fines are thousands of dollars each day for each mistake. If you break rules on purpose, the cost gets even higher. One accident can cost millions. Here is how fines can add up:

Compliance Risk | Average Cost of Fines |

|---|---|

FRA Safety Regulations | $3,000 to $25,000 per day per infraction |

Willful Violations | Up to $105,000 per incident |

Unplanned Downtime | Up to $1,000 per hour |

Liability from Accidents | $7 million per incident |

Big companies have paid huge amounts for breaking rules. Volkswagen paid over €30 billion for an emissions scandal. Amazon got a fine of more than $800 million for data privacy issues. Westpac Bank paid nearly $1 billion for not following anti-money laundering laws. BP spent about $65 billion after the Deepwater Horizon disaster. These numbers show how hidden costs from compliance failures can destroy profits.

In shipping, not following sanctions can mean fines in the millions. You need a strong plan to keep up with changing rules. If you do not, you risk fines, lost business, and legal trouble.

Reputational Damage

Fines hurt your wallet, but damage to your reputation lasts longer. When you break rules, people start to doubt your business. Customers may leave and look for someone they trust more. Bad news spreads quickly, especially online. One mistake can make headlines and scare away new partners.

Impact Type | Description |

|---|---|

Non-compliance can make your company look careless or dishonest. | |

Diminished Trust | People may stop believing in your promises. |

Customer Loss | Customers may switch to other companies they trust more. |

Erosion of Customer Trust and Loyalty | Loyal customers may leave and stop recommending you. |

Negative Publicity | News stories about mistakes can spread quickly and widely. |

Long-lasting Public Perception Issues | Bad news can stick around for years, making it hard to recover. |

You can pay a fine with money, but fixing your name takes much longer. The hidden costs of lost trust and bad press can follow your business for years.

Process Issues

Documentation Errors

Paperwork mistakes happen more often than you think. If you use manual processes, you might spend days fixing errors. One in three freight delays comes from missing or wrong documents. These mistakes can cause customs holds, extra fees, and lost sales. You might even face penalties if you do not fix them quickly.

Company | Process Type | Average Document Cycle Time | Yearly Compliance Penalty | Documentation Errors |

|---|---|---|---|---|

Company A | Manual Process | 48–72 hours | ~$12,000 | 6–10 corrections per week |

Company B | With Logistics Software | 12–18 hours | $0 | Eliminated 95% of errors |

When you use digital tools, you make fewer mistakes and work faster. You also avoid many hidden costs from fixing mistakes and paying penalties.

Tip: Check your paperwork often. Even small errors can lead to big problems and extra costs.

Poor Coordination

When teams do not work together, things go wrong. Trucks sit still, wasting time and money. Miscommunication leads to late or wrong deliveries. This upsets customers and makes them lose trust in you. Manual time tracking can cause overbilling, while messy paperwork slows down billing and cash flow. Your team spends more time fixing problems than doing their real jobs. This lowers morale and makes people want to leave.

Idle trucks mean lost time and less work done.

Miscommunication causes late or wrong deliveries.

Manual tracking leads to overbilling and wasted resources.

Disorganised paperwork delays billing and cash flow.

More time spent on problems lowers team morale.

Poor coordination creates hidden costs that you might not see right away. Over time, these problems add up and make your business less competitive.

Note: If you want to avoid these hidden costs, focus on clear communication and better teamwork. Small changes can make a big difference.

Why Hidden Costs Persist

Fragmented Data

Your data is kept in many places. Different teams or companies handle it. Using several logistics providers makes costs go up fast. Each provider works in its own way. You spend more time and money to keep things working. You might chase emails or fix mistakes. Sometimes you wait for updates. This takes away your profits. It makes cost control harder.

Fragmented supply chains need more resources. You must manage and coordinate them. Manual communication slows you down. Document processing also pushes up costs. Incomplete data can raise logistics costs by 30%. You might have bad routes or too much stock. Sometimes you pay extra for urgent shipping. Nearly 40% of logistics managers say costs are higher with many providers. Poor communication between suppliers and manufacturers causes problems. You might make too much or run out of stock. Both hurt your profits.

Tip: Put your data together in one place. This helps you spot problems and save money.

Poor Visibility

If you cannot see your supply chain, you lose control. Poor visibility causes confusion and mistakes. You might not know where your goods are. You may not know if they will arrive on time. This can lead to hidden costs.

Hidden Costs | Affected Areas |

|---|---|

Avoidable chargebacks | Food and beverage shipping |

Expedited shipping costs | General logistics operations |

Detention fees | Food and beverage shipping |

Inventory mismanagement | General logistics operations |

Temperature excursions leading to spoilage | Food and beverage shipping |

OTIF penalties | General logistics operations |

Stockouts and lost sales | Retail operations |

Excess inventory and holding costs | Manufacturing and retail operations |

You might get big chargebacks if teams do not work together. Some companies lose up to $1.5 million each year this way. Delays mean you pay for faster shipping. This can cost five to ten times more than normal. If you cannot see your inventory, you risk running out or having too much. Both cause lost sales and unhappy customers.

Poor visibility leads to confusion and lost profits.

Chargebacks and penalties add up fast.

Expedited shipping cuts into your margins.

Inventory mistakes mean lost sales or wasted money.

Legacy Processes

Old ways of working are hard to change. You might feel safe with your current systems. They may be slow or outdated. Many people worry that automation or AI will take jobs. Some teams do not want to lose control. Others trust their old systems and feel proud of them.

Legacy processes stay because:

People want to avoid losses, not try new things.

Familiar systems seem safer, even if they are slow.

New tools make people feel unsure.

Teams may work alone or fear losing their status. Sometimes no one knows who owns a process. This means nothing changes. Complex approval steps slow down change. A risk-averse culture also makes it hard to modernise. If you keep using old processes, hidden costs keep growing.

Note: Change can feel risky. But sticking with old habits often costs you more over time.

Limited Analytics

You might think you have all the numbers you need, but limited analytics can hide the real story in your logistics. When you cannot see the full picture, you miss out on ways to save money and work smarter. Many companies still use basic reports or spreadsheets. These tools only show you what happened, not why it happened or how to fix it.

If you do not use advanced analytics, you often guess where your money goes. You might spot a problem after it has already cost you. For example, you may notice high transport costs, but you cannot tell if it comes from poor route planning, empty trucks, or slow loading times. Without the right tools, you cannot dig deeper.

Here’s what happens when you rely on limited analytics:

You miss patterns in your data. Problems repeat, and you do not know why.

You cannot track costs across your whole supply chain. Some costs stay hidden in different teams or systems.

You react to problems instead of stopping them before they start.

You struggle to measure the impact of changes or new ideas.

Tip: If you want to find hidden costs, you need to see the whole journey of your goods, from supplier to customer.

Data often sits in silos. One team keeps their own records. Another team uses a different system. This makes it hard to put all the information together. When your data is fragmented, you cannot run a full analysis. You miss out on chances to spot waste or delays. You also lose the chance to compare suppliers or routes in real time.

Advanced technology, like AI and IoT, can help you break down these barriers. These tools collect data from every part of your operation. They show you where you spend too much or where you can save. When you use smart analytics, you can:

Streamline your operations and cut down on wasted time.

Optimise how you use your trucks, staff, and warehouse space.

Spot trends before they become costly problems.

A simple table can show the difference:

Analytics Level | What You See | What You Miss |

|---|---|---|

Basic Reports | Past costs, simple totals | Root causes, hidden trends |

Advanced Analytics | Real-time insights, forecasts | Fewer surprises, more savings |

If you want to stay ahead, you need more than just numbers. You need insights that help you act fast. With better analytics, you can find hidden costs and fix them before they grow.

AI Solutions

You may ask how to fix hidden costs in logistics. AI helps you see problems as they happen. It can also predict what might go wrong. This lets you make better choices each day. Here is how these tools work for you.

Real-Time Monitoring

You need to know what is happening right now. Real-time monitoring lets you spot issues early. AI tools watch your shipments, vehicles, and stock all the time. You get alerts if something is not right. This means you can fix things fast and keep customers happy.

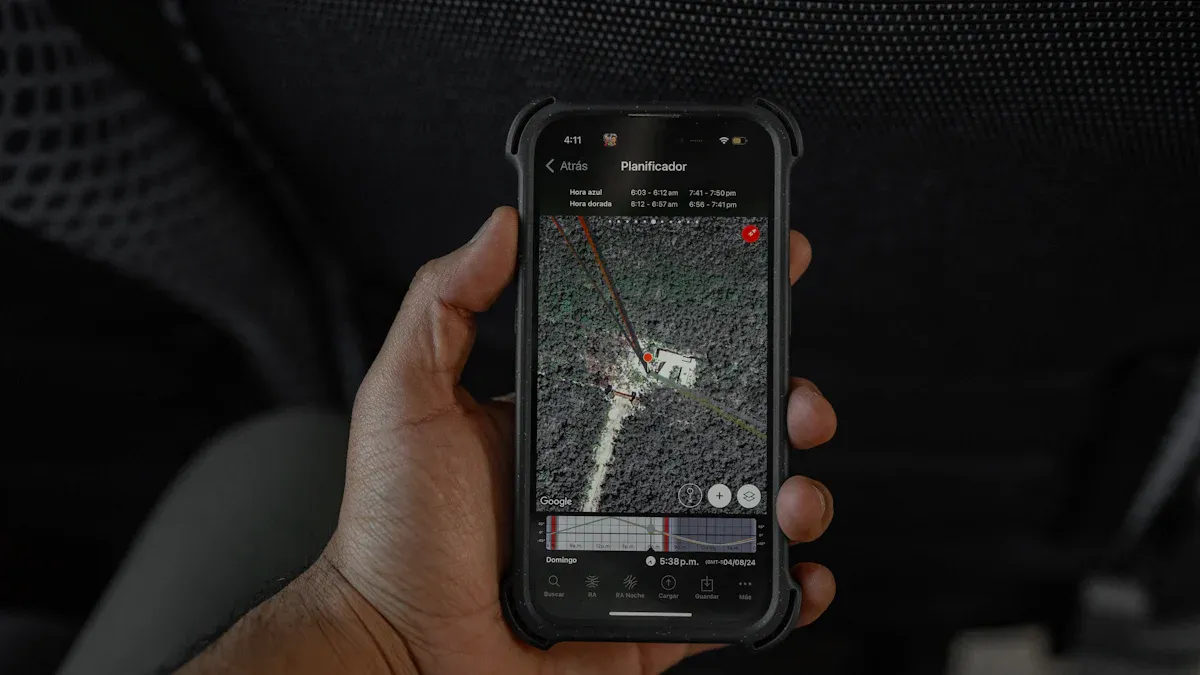

Geofencing

Geofencing makes invisible borders around places. When a truck enters or leaves, you get a message. You can track animals, expensive goods, or special shipments easily. Geofencing helps you stay in control and act quickly.

Aspect of Impact | Description |

|---|---|

Real-time Tracking | You always know where your vehicles are, so nothing goes missing. |

Optimised Route Planning | You can change routes quickly, saving time and fuel. |

Improved Customer Satisfaction | Customers get correct delivery times, so they trust you more. |

Enhanced Security | You spot theft or loss fast, keeping your goods safe. |

Increased Operational Control | You make better choices with more data, cutting costs and gaining control. |

You do not need to guess where your goods are. Geofencing gives you clear facts, so you can act with confidence.

Live Inventory

AI checks your stock levels all the time. You see what is in your warehouse, on the road, and what is running low. This stops you from having too much or too little. You save money on storage and avoid missing sales.

Demand prediction gets about 8% better. You deliver on time and avoid shortages.

You cut extra stock by 10%. Storage costs drop, and your cash flow improves.

GPS and mobile trackers show where expensive shipments are at all times.

Sensors for temperature, humidity, and shock help protect goods in cold chain logistics. You get instant updates and can fix problems before goods spoil.

Tip: When you know what you have and where it is, you make better choices and keep customers happy.

Predictive Analytics

You want to plan ahead, not just react. Predictive analytics uses AI to look at old data and find patterns. It helps you guess demand, manage stock, and avoid costly surprises.

Forecasting

AI tools study your sales, market trends, and even weather. You get good guesses for demand and supply. This means you order the right amount, plan transport, and keep costs low.

Predictive analytics helps you keep stock at the right level, so you do not run out or overstock.

You save money by managing stock better and making more profit.

Good demand forecasts let you plan space and avoid paying extra for urgent shipments.

These tools use real-time and old data to spot demand spikes. You can book carrier space early and avoid high prices.

By looking at traffic and weather, you pick better routes and predict delivery times. This cuts delays and saves fuel.

You do not have to guess. AI gives you the numbers you need to make smart choices.

Disruption Alerts

AI watches for risks and warns you before problems start. You get early alerts about traffic, bad weather, or supplier delays. This helps you act fast and avoid losses.

Companies using AI for alerts see a 15% drop in logistics costs.

Early users manage stock 35% better.

Automation can cut your money risk from problems by at least 20%.

One transport firm made forecasts 15% better and lowered stock by 10% with AI.

A Japanese consumer goods company saved $100 million by using AI to improve operations.

“AI can see how things may change and help you plan faster than people, so businesses can spot risks before they happen.” – Shirley Hung, Partner, Everest Group

You feel calm knowing you can handle surprises and keep your business running well.

Smart Scheduling

You want every delivery to be on time. Smart scheduling uses AI to plan routes and loads. This makes sure you use your resources well and save money.

Route Planning

AI looks at traffic, weather, and delivery times. It finds the best routes for your drivers. You spend less on fuel and get goods to customers faster.

Benefit | Description |

|---|---|

Time Savings | Automated route planning lets your team focus on important jobs. |

Rapid Re-routing | AI changes routes in minutes if things change, keeping deliveries on time. |

Accurate ETAs | You give customers reliable delivery times, building trust and helping planning. |

Fuel Cost Reduction | You can cut fuel costs by up to 15% with AI route planning. |

AI plans routes, so you do less manual work.

Fast re-routing keeps your service good, even when things go wrong.

Accurate ETAs make customers happy and help your team plan better.

Load Optimisation

AI helps you fill every truck or container well. You avoid sending half-empty vehicles, which wastes money. You also need fewer trips, saving time and fuel.

AI scheduling tools can save you up to 20% on run rates.

Businesses that optimise scheduling see 15% fewer supply chain problems.

Smart scheduling boosts efficiency by matching loads to the right vehicles and routes.

You save money and make your supply chain stronger.

Note: When you use AI for scheduling, you get more done with less effort. Your team works smarter, not harder.

AI solutions give you the tools to see, plan, and act. You spot problems early, make better choices, and keep your business moving forward.

Automated Documentation

Automated documentation changes the way you handle paperwork in logistics. You no longer need to chase missing forms or worry about lost files. AI tools take care of the details, so you can focus on moving goods and keeping customers happy.

Digital Paperwork

Paperwork can slow you down. Manual forms often lead to mistakes, delays, and extra costs. With digital paperwork, you let AI handle the heavy lifting. You scan, upload, and store documents in one place. The system checks for errors and fills in missing details. You get alerts if something needs your attention.

Here’s how automated documentation helps you every day:

Benefit | Description |

|---|---|

Accuracy | Automated checks make sure your documents are correct and complete. You avoid costly errors. |

Streamlined Workflows | Digital forms speed up your work. You skip manual steps and finish tasks faster. |

Real-time Visibility | You see where each document is in the process. You spot problems before they grow. |

Cost Savings | You spend less time on paperwork. Your team can focus on bigger jobs. |

Enhanced Transparency | You track every step. This helps you follow rules and prove what happened if needed. |

You do not need to worry about losing paperwork or missing a deadline. Everything stays organised and easy to find. Digital paperwork also helps you work better with partners and customers. Everyone sees the same information, so there is less confusion.

Tip: Switch to digital paperwork to cut down on errors and speed up your logistics.

Compliance Tools

Staying on top of rules and regulations can feel overwhelming. Laws change often, and missing an update can cost you money or damage your reputation. AI-powered compliance tools help you stay ahead.

Here’s what these tools do for you:

AI scans legal websites and databases all the time. You get alerts when rules change, so you never miss an update.

The system checks your data and rates your risk. You see which problems need fixing first.

AI creates reports and audit trails for you. You save time and always have proof for inspections.

The tools reduce false alarms. You only get alerts that matter, so you do not waste time.

Automated checks make your compliance work faster and cheaper. Even small teams can keep up.

You stay up to date with global rules. The system watches for changes and keeps you informed.

You do not need to guess if you are following the rules. AI keeps you on track and helps you avoid fines. You also build trust with customers and partners because you can prove you follow the law.

Note: Automated compliance tools give you peace of mind. You can focus on growing your business, knowing you are covered.

Overcoming Barriers

Data Integration

You might want to use AI in logistics, but joining up your data can be hard. Many companies find it tricky to put all their information together. Sometimes, data is kept in different places and systems do not share it. You might have missing bits or messy records. This makes it tough for AI to help you make good choices.

Here are some common problems:

| Challenge | Description | | Inconsistent, incomplete, or siloed data | Many systems in a supply chain do not share data, so information gets split up. This makes it hard for AI to help with decisions. | | Need for clean and high-quality data | Data is often spread out on different platforms, so cleaning and joining it takes a lot of time and money. | | Complexity of integrating AI with legacy systems | Logistics companies find it hard to mix new AI tools with their old systems. |

Start by tidying up your records and making sure your systems can share data. Try to bring your information into one place. This helps you spot problems and lets AI work better for you. If you have old systems, look for tools that connect easily. You do not need to fix everything at once. Small steps can help a lot.

Tip: Begin with one area, like inventory or transport. When you see results, you can try other parts of your business.

Organisational Buy-In

Getting everyone to support AI can feel difficult. Some people worry about change or losing control. Others do not trust new technology. You need your team and leaders to support AI for it to work.

To get people to support AI in logistics, start with small projects that fix clear problems. Build trust and find leaders who will support you. Show how AI helps by sharing good results. This helps you get more people interested in using AI.

Using AI well means teams must work together. Make sure everyone knows their job and shares the same goals. This stops teams from working alone and helps AI get used faster.

You can build trust by showing quick wins. Pick a problem that slows you down and use AI to fix it. Share the results with your team. When people see the benefits, they want to join in. Work together across departments. Make sure everyone knows their role and how AI helps them.

Choosing Tools

There are many AI tools to pick from. Choosing the right one can save you time and money. Look for tools that fit your needs and work with your current systems. Some tools help you save money, while others make deliveries faster.

Here are some things to think about:

| Criteria | Description | | Integration with 3PL expertise | Using AI tools with third-party logistics helps manage physical logistics. | | Scalability | AI tools should be able to grow as your business grows. | | Cost management | AI can help find and cut hidden costs in logistics. | | Handling operational inefficiencies | AI tools should help with things like last-mile delivery and empty truck miles. | | Advanced AI capabilities | 74% of shippers would switch to 3PL providers with better AI tools. |

You do not need the fanciest tool. Choose one that solves your biggest problem first. Make sure it can grow with your business. Ask your team what features matter most. If you work with third-party logistics, pick a tool that fits their way of working. This helps you get the most out of your investment.

Note: The right AI tool should make your job easier, not harder. Try a few options before you decide.

Getting Started with AI

Assess Operations

Before you use AI, you need to know your current situation. Look at how your supply chain and logistics work now. Doing a full check helps you find problems and see if you are ready for AI. Sometimes, outside experts can help you spot things you might not notice.

Here is a simple table to help you check your operations:

Step | Description |

|---|---|

1 | Do a supply chain check and look at your operations to see if you are ready for AI. You can ask third-party experts for a better review. |

2 | Make sure your data is managed well and your systems are strong enough for AI. You might need to improve your IT or use cloud platforms. |

Check your data too. Is it tidy and easy to get? Good data helps AI work well. If your systems are old or do not connect, you may need to update them. Cloud platforms help you store and share data quickly.

Tip: Knowing your operations clearly helps you pick the best AI tools and avoid problems later.

Set Objectives

Once you know where you are, set your goals. Think about what you want AI to do for your business. Do you want faster deliveries? Lower costs? Happier customers? Talk with your team about your biggest problems.

Use these steps to set good goals:

Learn how AI can help your business work better and make customers happy.

Meet with important people to find out your main problems and places to grow.

Turn your top needs into clear, measurable goals that match your plans.

Choose KPIs to check if AI is helping, like quicker deliveries or better stock accuracy.

When you have clear goals, you can see your progress. You will know if AI is helping you. KPIs like faster deliveries or better stock accuracy show real results.

Note: Clear goals keep everyone working together and make it easier to show how AI helps.

Pilot Projects

You do not need to change everything at once. Start with a small test project. Pick one area where you can see quick results. Try AI for planning routes or tracking stock. A small test helps you learn fast and fix problems early.

Ask your team for feedback. Find out what works and what needs changing. If the test goes well, you can use AI in other parts of your business. Taking small steps helps everyone get used to new tools and builds confidence.

Callout: Small successes build trust. A good test shows your team and leaders that AI can really help.

Team Training

You might think AI is all about fancy software, but your team is just as important. If you want your AI project to work, you need to help your people feel comfortable with new tools. Many workers worry about change. Some fear they will lose their jobs. Others just do not know how to use the new systems. You can fix this with good training.

Start by showing your team why AI matters. Explain how it will make their jobs easier, not harder. Use real examples from your business. Maybe AI will help them spend less time on paperwork or avoid late-night calls about missing shipments. When your team sees the benefits, they will feel more excited to learn.

Here are some simple steps to get your team ready:

Hold a Kick-off Session

Bring everyone together. Show them what AI can do. Let them ask questions. You want them to feel part of the journey.Offer Hands-on Training

People learn best by doing. Set up practice sessions. Let your team try the new tools with real data. If they make mistakes, that is okay. They will learn faster this way.Create Easy Guides

Write simple instructions. Use pictures or short videos. Keep the language clear. Your team can use these guides when they get stuck.Pick AI Champions

Find a few team members who love learning new things. Train them first. They can help others and answer questions. This builds trust and keeps everyone moving forward.Check Progress Regularly

Ask your team how they feel. Are they confident? Do they need more help? Use surveys or quick chats. Change your training if you need to.

Tip: Celebrate small wins! If someone uses AI to solve a problem, share their story. This boosts morale and shows others what is possible.

You can also use a simple table to track your training plan:

Step | Who Leads | When | How to Measure Success |

|---|---|---|---|

Kick-off Session | Project Lead | Week 1 | Attendance, Questions |

Hands-on Training | IT Trainer | Week 2-3 | Practice Scores |

Guides Shared | Team Lead | Week 2 | Downloads, Feedback |

AI Champions Named | Manager | Week 3 | Number of Champions |

Progress Check | HR | Ongoing | Survey Results |

Remember, you do not need everyone to be an expert. You just want your team to feel confident and open to change. When your people know how to use AI, your whole business gets stronger. Training is not a one-time thing. Keep learning as you go. New tools will come, and your team will be ready for them.

Future Trends

Supply Chain Visibility

You want to know what is happening in your supply chain at every moment. In the future, AI will make this much easier. You will not need to guess where your goods are or worry about sudden problems. AI will help you see everything as it happens.

Let’s look at some of the most exciting trends that will shape supply chain visibility:

Trend | How It Helps You |

|---|---|

You get a steady flow of data from all your systems. This means you can spot issues and fix them quickly. | |

Predictive Disruption Alerts | AI models warn you before things go wrong, like stock running out or shipments getting delayed. You can act early. |

Decision-Support at the Point of Impact | AI gives you advice right when you need it. You can make smart choices fast and stop small problems from growing. |

You will see more companies using AI to join up their data. This means you can track goods from the factory to the customer. You will get alerts if something looks wrong. You can even get tips on what to do next. AI will help you plan for busy times, avoid delays, and keep your customers happy.

Tip: Start using tools that give you real-time updates. You will feel more in control and ready for anything.

Long-Term Benefits

When you use AI in your logistics, you do not just fix today’s problems. You set yourself up for long-term success. AI helps you save money, work faster, and keep your customers coming back.

Here are some long-term benefits you can expect:

Lower Costs: AI helps you spot waste and cut out extra steps. You spend less on storage, fuel, and labour.

Better Planning: You can see trends and plan for the future. This means fewer surprises and more steady growth.

Happier Customers: When you deliver on time, people trust you. They are more likely to buy from you again.

Stronger Teams: Your staff spend less time fixing mistakes. They can focus on important work and feel proud of what they do.

Faster Growth: With fewer problems, you can take on more orders and grow your business.

You will also find it easier to follow new rules and keep your business safe from fines. AI keeps an eye on changes in the law and helps you stay up to date.

Note: The sooner you start using AI, the sooner you will see these benefits. Small changes now can lead to big wins in the future.

You do not need to wait for the future to arrive. You can start today and watch your business get stronger, smarter, and more successful.

You’ve seen how hidden costs in logistics can drain your profits and slow you down. AI gives you the power to spot problems early and make smarter choices. If you act now, you can boost efficiency and stay ahead of your competitors.

Cut waste and save money

Deliver on time and keep customers happy

Build a stronger, more agile team

Ready to transform your logistics? Start exploring AI solutions today and watch your business thrive.

FAQ

What are hidden costs in logistics?

Hidden costs are extra expenses you do not see right away. These can include wasted fuel, overtime pay, storage fees, or fines. They slowly reduce your profits and make your business less efficient.

How does AI help reduce logistics costs?

AI spots problems early. It helps you plan better routes, manage stock, and avoid mistakes. You save money by cutting waste and working faster. AI also gives you real-time updates, so you can act quickly.

Is AI hard to set up in my business?

You can start small. Many AI tools work with your current systems. You do not need to change everything at once. Begin with one area, like tracking deliveries, and grow from there.

Will AI replace my team?

AI will not replace your team. It helps them do their jobs better. Your staff can spend less time on boring tasks and more time solving real problems. AI supports your team, not replaces them.

Can AI help with compliance and paperwork?

Yes, AI checks your documents for errors and keeps you up to date with rules. You spend less time on paperwork and avoid costly mistakes. Digital tools make audits and reports much easier.

How quickly will I see results from AI in logistics?

You can see small wins in weeks. For bigger changes, it may take a few months. Start with a pilot project. Track your progress and share results with your team.

What if my data is messy or in different places?

Start by cleaning your data and bringing it together. Many AI tools help you organise information. Good data makes AI work better and helps you find hidden costs faster.

Do I need a big budget to use AI in logistics?

You do not need a huge budget. Many AI solutions are affordable and scale as you grow. Start with one tool that solves your biggest problem. You can add more features as your business grows.

TangBuy: A Smarter Way to Dropship in 2025

If you're looking to stay competitive with dropshipping in 2025, speed and trend-awareness are key. TangBuy helps you stay ahead with real-time product trends, fast fulfilment, and factory-direct sourcing. With over 1 million ready-to-ship items, 24-hour order processing, and seamless Shopify integration, TangBuy makes it easier to test, scale, and succeed in today's fast-moving eCommerce landscape.

See Also

Understanding The Real Expenses Of Drop Shipping In 2025

Common Supplier Communication Errors And Their Solutions

Strategies For Managing Shipping Costs In Dropshipping