Navigating Supplier Changes: How to Achieve a Smooth, Reliable, and Risk-Free Transition

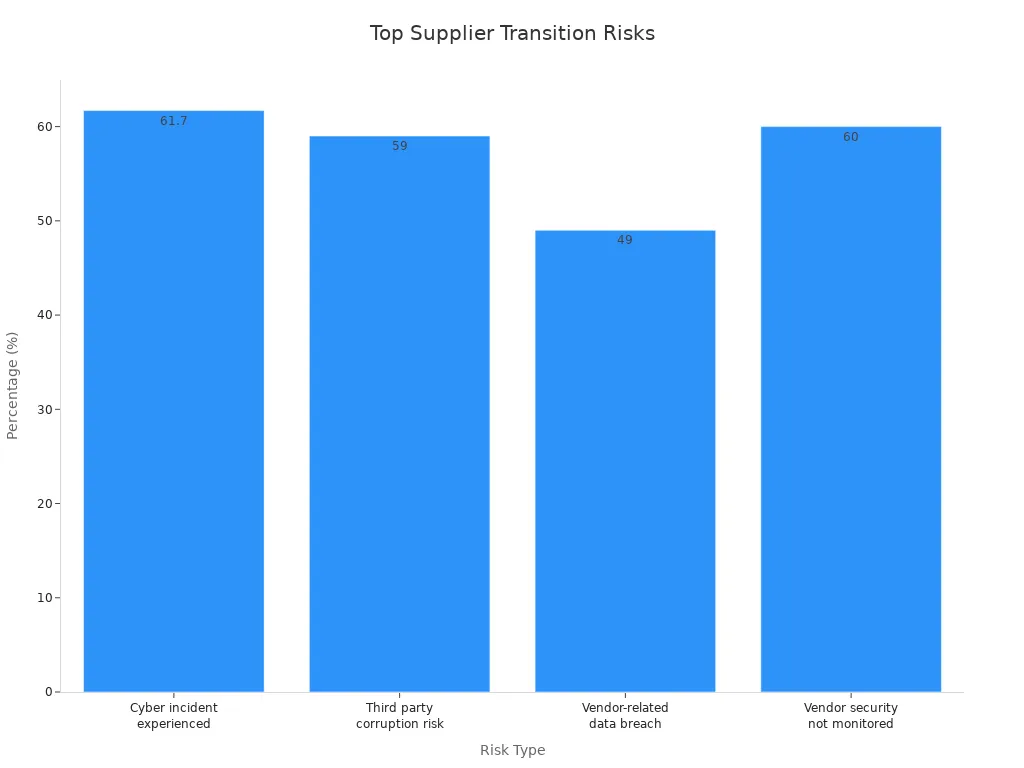

You might feel worried when facing supplier changes. You want things to go smoothly and keep risks low. Many businesses share your concern. Recent surveys show that over half of organisations report cyber incidents and data breaches when switching suppliers. Take a look at this chart to see the most common risks:

If you plan ahead, talk openly, and watch for problems, you can manage these risks. You might even discover new ways to improve your business.

Key Takeaways

Make a plan early to handle supplier changes well. Getting ready soon lowers risks and keeps your business running.

Find out which parts of your supply chain are most important. Knowing key suppliers helps you focus and lower risks.

Use supply chain mapping to show how suppliers connect. This lets you see problems before they happen.

Talk clearly with everyone involved. Sharing news with your team and suppliers builds trust and stops mix-ups.

Set simple goals for changing suppliers. Decide what you want, like saving money or getting better quality.

Make a timeline for the change. Split the work into easy steps with deadlines so everyone knows what to do.

Create backup plans in case a supplier fails. Having other suppliers keeps your supply chain strong.

Check how suppliers are doing often. Use numbers to watch delivery, quality, and costs so you can fix problems fast.

Supplier Changes: Risk Assessment

Supplier changes happen in all businesses. You cannot stop them. You can get ready for them and lower risks if you start early. When you check your supply chain, you need to know what could go wrong. You also need to see how it might hurt your business. Let’s look at the steps you should follow.

Dependencies

You rely on many things when you change suppliers. Some dependencies matter more than others. You need to find these early.

Criticality

Some parts of your supply chain are very important. If you lose a key supplier, your whole business might stop. You should ask, “Which suppliers are vital for my business?” You can use a table to see common dependencies that affect supplier change risk in manufacturing and retail:

Dependency Type | Description |

|---|---|

Extreme Weather | Storms and floods can stop deliveries and supply chains, like the Texas snowstorm and Suez Canal blockage. |

Technology Dependencies | Shortages in key parts, like microchips, can stop production in many industries. |

Cybersecurity Threats | Data breaches and malware can harm supply chain work, especially with third-party services. |

Global Risks | Political problems and trade rules can break supply chains, as seen with the Russian-Ukrainian war. |

Natural Risks | Disasters like earthquakes and floods can damage buildings and stop work, so you need backup plans. |

You should check each dependency and see how important it is. If a supplier gives you something you cannot get quickly, mark it as vital.

Impact Mapping

You need to see how supplier changes affect your whole supply chain. Supply chain mapping helps you do this. Here’s how you can map the impact:

Supply chain mapping lets you see all supplier links.

It helps you spot dependencies and places where problems might start.

You can add different levels of sub-suppliers based on how important they are.

You can follow these steps:

Look closely at your suppliers and what they do.

Include all suppliers and details in your map.

Make a full map to get good ideas about your supply chain.

When you map your supply chain, you find weak spots and places where trouble might begin. This helps you plan for risks before they happen.

Risk Types

You face different risks when you change suppliers. You need to know what they are so you can get ready.

Operational

Operational risks affect your daily work. If a supplier cannot deliver on time, your production might stop. Technology problems or broken processes can also cause trouble. You should watch for these risks and have backup plans.

Financial

Financial risks can hurt your profits. If a supplier has money problems, they might close down. You could lose money or face surprise costs. You should check every supplier’s financial health before making changes.

Here’s a table showing the main risk types you should think about:

Risk Category | Description |

|---|---|

Financial Health | Check the supplier's money strength and performance. |

Political Stability | Look at the political situation in the supplier's area. |

Infrastructure Risks | Check if the supplier’s buildings and systems work well. |

Natural Disaster Risks | Think about how likely disasters are and how they could hurt the supplier’s location. |

Prioritisation

You cannot fix every risk at once. You need to choose which risks matter most. Companies use frameworks like Enterprise-wide Risk Management (ERM) to help with this. ERM gives you a clear way to look at all risks together and make smart choices.

Use ERM to manage all risks in a careful way.

Interim executives do risk checks, talk to people, and use data to pick top risks.

Make quick risk plans that can change if needed.

You can sort risks by type:

Strategic Risks: These come from changes in your business plans.

Operational Risks: These happen when your systems or processes break.

Financial Risks: These rise during leadership changes or big changes and can cause money problems.

When you pick the most important risks, you use your resources where they help most. This keeps you ready and stops surprises.

Tip: Collect old data on past supplier changes and industry effects. This helps you see patterns and guess future risks.

You can also use Supplier Relationship Management (SRM) tools. SRM helps you find, check, and handle supplier risks as they happen. Regular risk checks and watching all the time let you spot trouble before it grows. When you work well with suppliers, you build strong partnerships and get better at handling problems.

Transition Planning

Planning helps you when you change suppliers. You want things to go well, so you need a good plan. Good planning stops surprises and keeps your business working.

Objectives

Start by making clear goals for your supplier transition. What do you want to get from this change? Maybe you want better quality, lower prices, or faster deliveries. You might also want to have better relationships with new suppliers. When you set goals, you can check if you reach them. Here is a table to show some common goals and how to measure them:

Key Objective | Measurement Metric |

|---|---|

Improving product quality | Defect rates |

Reducing costs | Cost savings |

Enhancing delivery performance | On-time delivery |

Fostering better relationships | Supplier responsiveness |

Pick the goals that are most important for your business. Check how you are doing often. If you find problems, you can fix them quickly.

Timelines

You need a timeline for your supplier change. Timelines help everyone stay on track. First, write down all the steps you need to do. Give each step a finish date. Share the timeline with your team and suppliers. This way, everyone knows what to do and when.

Here are some tips for making your timeline:

Split the change into small steps.

Set a clear finish date for each step.

Add extra time in case things go wrong.

Check your timeline often and change it if you need to.

Tip: Use a simple calendar or project tool to track your timeline. This helps you see any delays before they get too big.

Resources

You need the right resources for your supplier change. Resources are people, money, and tools. Make sure you have enough staff for the extra work. Check your budget and save money for extra costs. Use checklists and software to help you stay organised.

Group purchasing can help you save money and use resources better. When you join a group purchasing organisation, you buy with other businesses. This gives you more power to get good prices. You spend less time on paperwork. Group purchasing also helps you manage resources during supplier changes.

Remember, good planning makes things easier. Set clear goals, make a timeline, and get your resources ready. You will feel more sure of yourself and ready for anything.

Communication

Good communication is very important when you change suppliers. You need to talk to the right people at the right time. This helps you find problems early. It also keeps everyone working together. Let’s look at how you can make communication help you.

Stakeholders

There are two main groups to think about. These are internal and external stakeholders. Each group needs different help and information.

Internal

Your team will notice supplier changes first. You should tell them what is happening as soon as you can. Early talks help you see which departments will be affected. You may need to speak to purchasing, logistics, finance, and IT. If you keep your team updated, you build trust. This also stops confusion.

Here is a table that shows good ways to talk to stakeholders and keep things calm:

Strategy | Key Components |

|---|---|

Communicate regularly | Use open and clear messages; send updates often; use different ways to talk. |

Build relationships | Listen to worries; have check-ins; ask for ideas; keep your promises. |

Involve stakeholders in decision-making | Let people join in; ask for ideas early; let them help with solutions. |

You can use meetings, emails, or quick chats to share news. If you ask for feedback, you show your team their thoughts matter.

External

External stakeholders are customers, partners, and regulators. You need to keep them informed too. If you tell them about changes early, they can get ready. You can send notices, update your website, or hold short meetings. If you answer questions quickly, you build trust and keep your good name.

Tip: If you share news often, you help everyone feel ready and involved.

Supplier Engagement

You must talk clearly with both old and new suppliers. This helps you avoid surprises. It also keeps your business working well. Every good change starts with understanding the problems. Open talks make sure everyone knows what will happen.

Here is an easy way to keep things clear:

Talk early. Tell suppliers about the change before it happens. Explain what is going on and let them know business will continue.

Be open. Say how the change affects contracts, payments, and deliveries. This helps build trust.

Introduce new owners. Set up talks between suppliers and the new owner. This helps everyone meet and sort out worries.

Keep things running. Share your plans to keep work smooth. Show you care about stopping problems.

Regular updates, feedback, and workshops help everyone feel part of the change. If you listen and reply, you build teamwork. Supplier Changes can seem hard, but honest talks make things easier for everyone.

Risk Mitigation

When you change suppliers, you want to keep your business safe. You can do this by planning ahead and making smart choices. Let’s see how you can protect your business with backup plans and strong contracts.

Contingency

You need backup plans for when things go wrong. If a supplier fails, you must act fast to keep your business running. Here are some ways to build a safety net:

Backup Suppliers

Having backup suppliers gives you more control. If your main supplier cannot deliver, you can switch quickly. This keeps your supply chain moving. Studies show using backup suppliers makes your business stronger and saves money. You avoid big problems and cut costs.

Strategy | Resilience (%) | Cost Impact (%) |

|---|---|---|

Excessive Inventory | Up to 60% more | |

Backup Suppliers | 72.72 | 40% less |

Difference | 13% more resilient under excessive inventory | N/A |

You do not need to keep too much stock. You just need reliable backup suppliers who can help when needed.

Tip: Watch for warning signs in your vendor relationships. If you see poor communication or hidden quality issues, act early. These problems often come before supply chain disruptions.

Inventory Buffers

Inventory buffers help you get ready for surprises. You keep extra stock of important items. This lets you keep working if a supplier is late or demand jumps. You can handle sudden changes without stopping your business.

Inventory buffers give you flexibility.

You can respond quickly to problems.

You reduce waste and keep service levels high.

If you manage your inventory well, you make your supply chain more agile. You can fix issues before they grow.

Here’s a checklist for your contingency planning:

Create action plans for each risk.

Add backup suppliers and inventory buffers.

Use technology to track supplier performance.

Make emergency response protocols.

Set up clear communication plans.

Contracts

Contracts protect you during supplier changes. You need to check your contracts and make sure they cover all risks. Good contracts help you avoid surprises and keep your business safe.

Key Clauses

Some contract clauses matter more than others. You should look for these when you review your agreements:

Importance | |

|---|---|

Clear service levels | Define what vendors must deliver and how you measure them. |

Audit rights | Give you the power to check supplier performance. |

Business continuity | Protects you during transitions and unexpected events. |

Transition support | Helps you switch suppliers smoothly. |

Data breach response | Keeps your sensitive data safe. |

Auto-renewal provisions | Stops you from getting stuck in bad contracts. |

Contract and risk oversight | Makes sure your contracts match your risk management plans. |

Always check that your contracts match your business needs. If you see gaps, fix them before you change suppliers.

Compliance

You must follow laws and industry standards. This keeps your supply chain secure and avoids legal trouble. When you check compliance, you protect your business from fines and other risks.

Compliance Requirements | Impact on Risk Mitigation Strategies |

|---|---|

Adherence to laws | Mitigates legal and regulatory risks |

Industry standards | Ensures a secure and compliant supply chain |

Note: If you see warning signs like cybersecurity problems or poor innovation, review your contracts and compliance plans. These issues can lead to bigger risks if ignored.

You can use technology to help you track compliance and supplier performance. This gives you better visibility and control.

Supplier Changes can feel risky, but with good backup plans and strong contracts, you can keep your business safe. You stay ready for anything and build a supply chain that works for you.

Opportunities

Changing suppliers can seem risky. But it can help your business grow. You can use this time to look at your supply chain. You might find better ways to work. Here are three big chances you get when you switch suppliers.

Cost Savings

You can spend less money by changing suppliers. Sometimes, your old supplier costs too much. They might have hidden fees. New partners can offer better prices. This helps you save money. Many companies have done this and seen good results.

Albert Brenner from Altraco said they moved some suppliers from China to Vietnam and India. This helped them avoid high tariffs. They saved money and made their supply chain stronger.

Gap Inc. lost lots of money by relying on suppliers in Vietnam during COVID-19. They lost about $300 million in sales. They paid an extra $430 million for air freight. After this, they worked with more suppliers in different places. This helped them avoid big losses later.

You can learn from these stories. If you check your supply chain and look for new places to buy from, you can save money. You can also avoid sudden problems.

Innovation

Changing suppliers can bring new ideas. New partners can share fresh views and new technology. Some suppliers use better machines or smarter ways to make things. This can help you improve quality and work faster.

You can ask new suppliers about their best ways of working. Some may offer custom solutions or suggest new materials. If you stay open to change, you can make your products better. You might even find new products or services for your customers.

Tip: Ask suppliers about their newest ideas. You might find something that helps you beat your competitors.

Sustainability

Many businesses care about the environment and doing the right thing. Changing suppliers lets you pick partners who share your values. You can choose suppliers who use green materials or fair labour.

Sustainable sourcing is important in manufacturing. It uses eco-friendly and fair methods.

This helps lower harm from making to using products.

More customers and suppliers want greener ways and clear facts about how things are made.

Companies that care about sustainability often work better and reach new markets.

Ford Motor Company uses sustainable fabrics and recyclable materials in its cars. They have strong rules for the environment. They also make their cars use less fuel.

You can use supplier changes to make your business greener and fairer. This helps you meet customer needs and build a better brand.

Remember: Every supplier change is a chance to check your supply chain. Look for ways to save money, get new ideas, and be more sustainable. You might find benefits you did not expect.

Monitoring

Watching your new supplier is very important. You want everything to work well. You should check how they do their job. Listen to what people say about them. Try to build a good relationship with your supplier. Here is how you can do this.

Performance

You need to see if your supplier is doing well. Checking their work helps you find problems early. You can fix small problems before they get bigger. Use simple ways to see if your supplier meets your needs.

Here is a table with common ways to check supplier performance:

Metric | Description |

|---|---|

Delivery Performance | Checks if your supplier brings things on time or late. |

Quality Performance | Looks at how many items are faulty or meet your standards. |

Cost Performance | Compares what you pay to what you thought you would pay. |

Lead Time Performance | Measures how long it takes for your orders to arrive. |

You can also check these things: defect rate, order accuracy, contract compliance, lead time, delivery performance, and cost performance.

If you check these often, you can spot changes quickly. You might see more mistakes or late deliveries. Then you can talk to your supplier and fix the problem.

Tip: Use a simple chart or spreadsheet to track these numbers. This helps you see changes and share news with your team.

Feedback

Listening to feedback helps you work better with your supplier. Ask your team and customers what they think about the new supplier. You can use surveys or quick talks to get their ideas.

Supplier Relationship Management (SRM) makes this easier. If you treat your supplier like a partner, you build trust. You can use Net Promoter Score to see if your supplier is happy to work with you.

When you use SRM, both sides get good things. You help your supplier get better, and they help you reach your goals. SRM is more than just contracts. It helps you find new ideas and keeps your supply chain strong.

Partnerships

Strong partnerships with suppliers help you do well for a long time. You want more than just a business deal. You want trust, shared goals, and teamwork.

Here is a table showing why partnerships are important:

Benefit | Description |

|---|---|

Access to Expertise | You get new ideas and advice from your supplier. |

Early Problem Detection | Working together helps you find problems before they get big. |

Adaptability | You can change quickly when the market changes. |

Partnerships also have these good points:

Characteristic | Description |

|---|---|

Long-term Trust | You build strong relationships based on trust. |

Collaborative Innovation | You work together to make products and processes better. |

Resilient Supply Chains | Fewer, stronger suppliers make your supply chain tougher. |

If you focus on partnerships, your supply chain can handle surprises. You get better results and help your business grow.

Remember: Monitoring is not something you do just once. Keep checking, listening, and working together. This helps you find problems early and see new ways to get better.

Tangbuy Advantage

Private Labelling

You want your products to be different from others. Tangbuy helps you do this with private labelling. You get to control your brand and how much money you make. You can pick how your products look and feel. You also choose the packaging. Tangbuy makes this easy and fast. You can place orders and get them ready in just 24 hours. There are more than one million items ready to send, so you do not have to wait long. You can see new trends as they happen and act quickly. Factory-direct sourcing means you get what you want straight from the factory. There are no middlemen to slow things down.

Private labelling with Tangbuy helps you move fast. If you notice a new trend, you can launch a product before others do. You can also change your designs or packaging to fit what your customers want. This makes it easier to grow your business and keep your customers happy.

Tip: When you use private labelling, you build a brand people remember. You also keep more profit because you control everything.

Manufacturer Collaboration

Working with manufacturers gives you lots of good things. You can design products that are special for your brand. You can ask for better features or higher quality materials. Tangbuy connects you straight to the factory, so you save money and time.

Here’s a table showing how working with manufacturers helps your brand:

Benefit | Description |

|---|---|

Product Differentiation | You can add special features and custom designs, so your products stand out. |

Quality Improvement | You set high standards, and the factory follows them, so your products are always top quality. |

Cost Efficiency | You save money because you buy directly and get better prices for bigger orders. |

Sustainable Production | Expert factories use less waste, so your products are better for the environment. |

You get more control over your products. You can make changes quickly if you need to. You also build strong relationships with the people who make your products. This helps you fix problems faster and keep your supply chain working well.

Customisation

Customisation is important if you want your business to grow. Tangbuy lets you make your products and marketing personal. You can show customers things they like, send them special deals, and even make loyalty programmes. This makes your customers feel special and want to come back.

Here’s how customisation helps your business:

Impact Area | Description | Example |

|---|---|---|

Enhances Customer Experience | Customers find what they want faster. | More people buy |

Builds Trust and Loyalty | Special offers make customers feel special. | Customers return more |

Increases Conversion Rates | Discounts and suggestions encourage quick purchases. | Sales go up |

Boosts Brand Differentiation | Tailored marketing makes your shop stand out. | People remember your brand |

Improves Customer Retention | Personalised emails keep customers interested. | Customers stay longer |

Loyalty Programme Integration | Points and rewards make customers loyal. |

You control your products and your profits.

Customisation makes your products feel special, so customers stay loyal.

Unique products mean less competition and more repeat sales.

When you use Tangbuy’s customisation tools, you make shopping easier and more fun for your customers. You also build a brand that people trust and remember.

Brand Growth

Growing your brand can feel like a big challenge. You want your products to stand out. You want customers to remember your name. Tangbuy gives you the tools to make this happen. When you use Tangbuy, you get more than just products. You get a partner who cares about your brand’s future.

You can start small and grow fast. Tangbuy lets you test new ideas without a huge risk. You can launch new products quickly. If you see a trend, you can act before your competitors do. This helps you stay ahead in the market.

Tip: Try launching a limited-edition product. See how your customers react. If it works, you can make it a regular item.

Tangbuy’s private labelling and customisation options help you build a brand that feels unique. You choose the look, the feel, and even the packaging. Your products will not look like everyone else’s. Customers notice this. They remember your brand because it feels special.

Here’s how Tangbuy supports your brand growth:

Speed to Market: You can bring new products to your shop in days, not months.

Flexible Orders: You do not need to order thousands of items. Start with small batches and grow as demand rises.

Direct Factory Access: You talk straight to the people who make your products. This means you get better prices and faster answers.

Custom Branding: You control your logo, colours, and packaging. Your brand stays front and centre.

Let’s look at some ways Tangbuy helps you scale up:

Growth Area | How Tangbuy Helps | Why It Matters |

|---|---|---|

Product Range | Add new items quickly | Meet changing customer needs |

Brand Recognition | Use custom labels and packaging | Build a loyal customer base |

Market Reach | Test products in new markets easily | Find new customers |

Profit Margins | Lower costs with direct sourcing | Keep more of your earnings |

You do not have to do it all alone. Tangbuy’s team helps you with every step. You get advice on trends, packaging, and even marketing ideas. If you have a problem, you get support fast.

Remember: A strong brand grows step by step. Use Tangbuy’s tools to try new things, listen to your customers, and keep improving. Your brand can become a name people trust and love.

You can handle supplier changes with confidence. Start with a clear plan. Talk openly with your team and suppliers. Watch your supply chain closely. These steps help you avoid surprises and keep your business strong.

Remember: Every change brings a chance to grow. If you want extra support, Tangbuy can help you build a better brand and supply chain.

FAQ

What is the first step when changing suppliers?

Start by checking your current supplier’s performance. Make a list of what you need from a new supplier. Set clear goals for the transition. This helps you avoid surprises.

How do you keep risks low during a supplier switch?

You can spot risks early by mapping your supply chain. Use backup suppliers and keep extra stock. Review contracts for strong protection. Talk openly with your team and suppliers.

Who should you tell about supplier changes?

You need to inform your team, customers, and partners. Share updates with everyone who might be affected. Use meetings, emails, or quick chats to keep people in the loop.

What if your new supplier does not meet expectations?

You should track their performance using simple charts or tables. Give feedback and ask for improvements. If problems continue, switch to a backup supplier.

Can supplier changes help you save money?

Yes! You can find better prices and avoid hidden fees. New suppliers may offer discounts or faster delivery. Review your supply chain for cost-saving opportunities.

How does Tangbuy help with private labelling?

Tangbuy lets you design your own products and packaging. You get direct access to factories. You can launch new items quickly and build a brand that stands out.

What tools help you monitor supplier performance?

You can use spreadsheets, charts, or Supplier Relationship Management (SRM) software. These tools help you track delivery times, quality, and costs. Regular checks keep your supply chain strong.

Tip: Always ask for feedback from your team and customers. This helps you spot issues early and improve your supplier relationships.

TangBuy: A Smarter Way to Dropship in 2025

If you're looking to stay competitive with dropshipping in 2025, speed and trend-awareness are key. TangBuy helps you stay ahead with real-time product trends, fast fulfilment, and factory-direct sourcing. With over 1 million ready-to-ship items, 24-hour order processing, and seamless Shopify integration, TangBuy makes it easier to test, scale, and succeed in today's fast-moving eCommerce landscape.

See Also

Common Supplier Communication Errors And Their Solutions

Maximising Profits By Sourcing Reliable Wholesale Party Supplies

Understanding Supplier Email Silence And Effective Remedies

Comprehensive Guide To Profitable eBay Selling In 2025

Detailed Guide For Starting Your Dropshipping Venture In 2025