Optimize Logistics for Q4 with Key Service Enhancements for Cross-Border Success

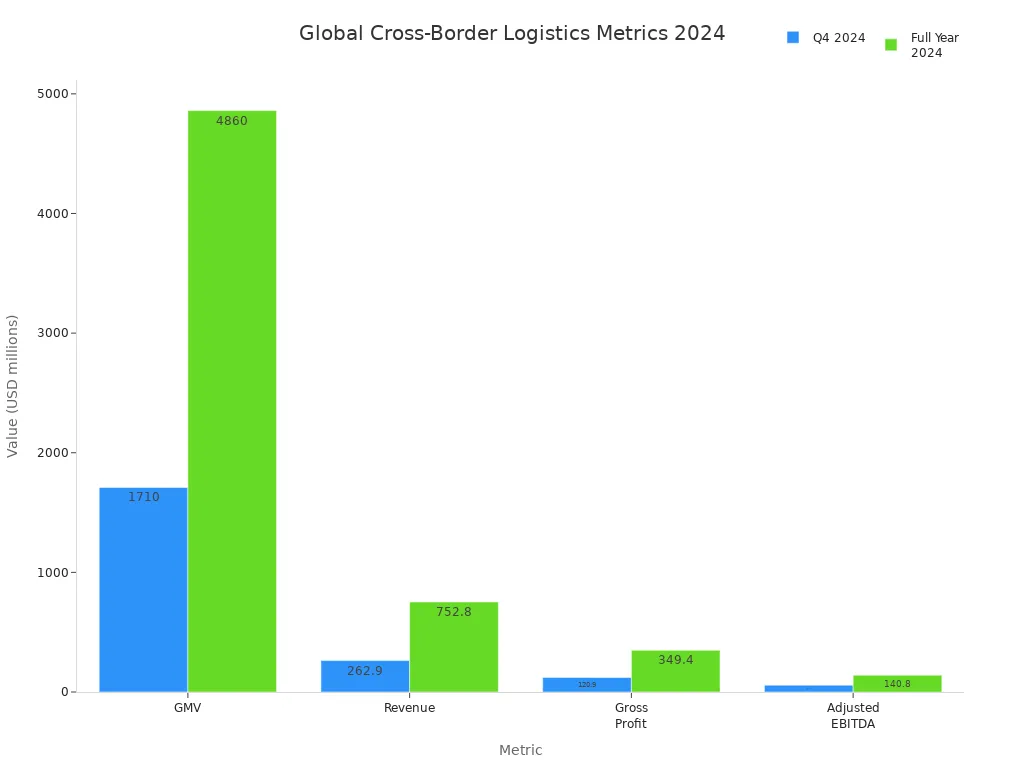

Q4 witnesses a significant surge in cross-border shipments, compelling logistics managers to act swiftly. The pressing question is whether they can manage increased order volumes and heightened customer expectations whilst striving to optimise logistics. The figures below illustrate the current landscape:

Metric | Q4 2024 Value | Q4 2024 YoY Growth |

|---|---|---|

GMV (Gross Merchandise Value) | +44% | |

Revenue | $262.9 million | +42% |

Gross Profit (Non-GAAP) | $120.9 million | +53% |

Adjusted EBITDA | $57.1 million | +62% |

Technology and automation have become crucial in the effort to optimise logistics. These tools provide teams with real-time visibility, enable faster quoting, and support more effective planning. Strategic partnerships further help companies to optimise logistics, reduce costs, and maintain customer satisfaction during the busiest periods.

Key Takeaways

Q4 has many more cross-border orders. Teams must plan inventory and delivery routes early. This helps stop delays and stock problems.

AI, IoT, and automation help teams track shipments live. They also help predict demand. These tools make warehouse and delivery work faster.

Certified carriers use proven processes. This cuts customs delays. It keeps shipments moving well during busy times.

Fast delivery, real-time tracking, and easy returns help customers. These things make customers happy and loyal in Q4.

Eco-friendly packaging and fuel-saving routes lower costs. They also help the planet. Deliveries stay quick and on time.

Teams track key performance indicators like on-time delivery. They also check cost per shipment. This helps find problems and improve service.

Teams use feedback and make quick changes. This keeps logistics flexible. It helps teams meet new market and customer needs.

New technologies like blockchain and autonomous vehicles are coming. They will make cross-border logistics faster, safer, and more reliable soon.

Q4 Cross-Border Challenges

Demand Spikes

Inventory Impact

Q4 has many shopping events that make cross-border logistics very busy. October starts with Singles Day, Canadian Thanksgiving, Diwali, and Halloween. November is busy with Singles Day, Black Friday, and Cyber Monday. December ends with Christmas and New Year’s, making deliveries even harder. Each event makes order numbers jump. Logistics teams must plan inventory well to stop running out or having too much stock. They often move goods closer to where people buy them and use more than one warehouse to keep up. In areas like perishables, teams need special equipment, like heated trailers, to keep goods safe from cold.

Q4 demand spikes push up cross-border volumes because of holiday shopping and year-end peaks.

Companies must guess demand early and put inventory near important markets.

Special equipment is needed for goods that need certain temperatures.

Delivery Timelines

Delivery times get shorter as customers want their orders fast, even when it is busy. Not enough operators and longer travel times can slow things down. Bad weather, strikes, and new rules make things less certain. Companies like DHL and UPS add extra charges and get more space to avoid problems. Logistics managers must change plans and routes every day to keep deliveries on time.

Customs and Compliance

Documentation

Customs clearance gets harder in Q4, especially for expensive goods like electronics and luxury items. Correct paperwork is very important. Mistakes with Harmonised System (HS) codes or missing papers can cause long delays and fines. Many companies now use automated checks and AI tools to make fewer mistakes and go faster.

Clearance delays often happen because of missing or wrong paperwork.

Wrong HS codes can cause tariff mistakes and stop shipments.

Many groups, like carriers and brokers, must work together closely.

Regulatory Updates

New tariffs and trade rules have made cross-border logistics harder. New import tariffs, stricter customs checks, and the end of de minimis thresholds in some places have raised costs and risks. Carriers have put up prices and added extra charges, so shippers must look at their carrier choices and how they pack. Planning early and being flexible helps companies handle these changes and avoid last-minute problems.

Customer Expectations

Speed

Customers now want fast, reliable delivery no matter where they shop. Big retailers like Amazon and Walmart have set high standards with next- and same-day shipping. Most shoppers want real-time tracking and clear delivery dates. Brands use more warehouses and local carriers to make delivery times shorter and cover more places.

Returns

Returns are now a big part of what customers expect. Many shoppers want to return items locally to avoid high costs and long waits. Tariffs and re-import duties can double the cost of returns, so companies must make returns easier. Brands that offer simple, clear returns earn trust and get more repeat buyers.

Tip: Logistics teams can make customers happier by giving live tracking, flexible delivery choices, and easy returns—especially during the Q4 rush.

Optimise Logistics: Service Enhancements

Technology Integration

AI & Analytics

AI and analytics have made a big difference in how companies optimise logistics, especially in Q4. Many companies now use AI systems to plan routes and manage freight. These tools help teams find quick routes and avoid traffic or bad weather. AI looks at lots of data to guess what customers will want. This helps companies keep enough stock and not run out. A study found that companies using AI in logistics made more money than others. AI also helps with fleet management. It finds problems early and keeps vehicles working well. Big companies like UPS and DHL use AI to deliver on time, even when there are lots of orders.

Demand forecasting stops too much or too little stock.

Predictive maintenance keeps vehicles running during busy times.

IoT Tracking

IoT tracking gives teams live updates on shipments. Sensors and devices connect across the supply chain to show where goods are and their condition. This technology helps companies optimise logistics by finding problems early and keeping customers updated. IoT tracking also helps suppliers, carriers, and retailers talk to each other better. Mobile and wireless tools help teams stay flexible and act fast.

IoT devices watch shipments and check their condition.

Live data helps teams fix problems before they get worse.

Wireless tech helps teams talk and make quick choices.

Automation

Automation makes logistics quicker and more dependable. Warehouse robots move goods fast and cut down on manual work. End-to-end automation links all parts of the supply chain, so orders move smoothly. Cloud computing lets companies manage data and see what is happening right away. Special software brings warehouse and fleet data together, helping teams optimise logistics and plan better.

Tip: Companies that automate their supply chain can handle Q4 spikes with less stress and fewer mistakes.

Customs Efficiency

Pre-Clearance

Pre-clearance makes customs checks go faster. Teams use the right incoterms, like DAP and DDP, to set duties and taxes before shipping. Express options help clear goods quickly. Planning by country, product, and weight keeps costs low and avoids delays.

Automated Documentation

Automated documentation cuts down on mistakes and saves time. Systems fill out forms and check codes, making customs easier. Parcel tracking keeps shipments visible during customs, so nothing gets lost.

Shipment Visibility

Real-Time Updates

Real-time updates let companies and customers see where shipments are at any time. Digital tools and AI platforms show important steps and warn about delays. This helps teams optimise logistics and keep everyone in the loop.

Tracking Platforms

Tracking platforms help customers trust the company. They give clear, quick updates and warn teams about problems. Advanced tech like IoT sensors and machine learning makes tracking smarter and more exact.

Real-time tracking helps everyone see the supply chain.

Fast alerts help teams fix delays quickly.

Clear updates make customers feel sure about their orders.

Carrier Partnerships

Certified Carriers

Picking the right carrier partners is very important in Q4. Certified carriers are special because they follow strict security and compliance rules. Many join programmes like CTPAT or FAST. These programmes help them get through borders faster and with fewer checks. They also get to use special lanes at crossings. This helps goods move quickly and avoids long delays. Fast delivery is very important when time matters.

Certified carriers also use new technology. They have electronic logging devices to track hours and keep drivers safe. They use automated customs systems, like ACE in the US or ACI in Canada. These systems help them send paperwork fast and without mistakes. This means less waiting at borders and shipments stay on time.

Note: Certified carriers might cost more, but they give peace of mind. They help companies avoid costly delays and keep customers happy during busy times.

Proven Processes

Good carrier partnerships are about more than just paperwork. They use proven processes to help optimise logistics from start to finish. These carriers know a lot about cross-border trade. They understand customs rules, security risks, and how to avoid slowdowns.

Here are some things to check when picking carrier partners: Check if they deliver on time and handle busy times well. Make sure their prices are clear, with all fees included. Look for good customer service and account managers who help you. Use carriers who can move goods by road, rail, air, or sea. Pick partners with a big network, so you have choices if one route is blocked. Ask how fast they fix problems when things go wrong.

Many companies now use cloud-based systems to track shipments at any time. They also meet with carriers often to check how things are going and plan for busy times. By working with trusted, certified partners who use proven processes, businesses can optimise logistics, lower risks, and keep goods moving—even when Q4 is very busy.

Sustainable and Cost-Effective Practices

Sustainability and saving money are now very important in cross-border logistics, especially in busy Q4. Companies want to help the environment and spend less at the same time. They use new technology, better packaging, and smart ways to manage resources to reach these goals.

Eco Initiatives

Packaging

Many logistics teams now use eco-friendly packaging. They pick materials that break down, can be recycled, or used again. This helps companies follow strict green rules and keeps customers pleased. The packaging market is changing fast, with more businesses choosing green options to make less waste. These materials might cost more at first, but they often save money later. Smart packaging also makes parcels smaller and lighter, which lowers shipping costs.

Companies using less plastic and more recycled paper get fewer fines and better reviews from customers.

Carbon Reduction

Cutting carbon emissions is now a big part of logistics planning. Some companies use electric trucks and build charging stations to lower pollution. For example, one provider added 16 electric trucks and built thousands of charging points. This helps the planet and gets the company ready for new zero-emission rules. Many businesses also use solar or wind power for their warehouses. Route planning software helps drivers skip traffic and use less fuel, which cuts emissions and saves money.

Cost Optimisation

Grouping Shipments

Grouping shipments is a clever way to save money. By putting small orders together, companies use truck space better and make fewer trips. This saves fuel, cuts down on labour, and lowers emissions. Load consolidation and pallet bundling help companies meet delivery targets without extra costs.

Cross-Docking

Cross-docking makes delivery faster by moving goods straight from the supplier to the customer, skipping storage. This cuts handling and storage costs. Goods spend less time travelling, which is important in Q4. When companies link transport and warehouse systems, they can track shipments live and fix problems quickly.

Grouping and cross-docking can lower transport emissions by up to 30%.

Automated load planning helps companies use all the space in their trucks.

Resource Integration

Parcel Models

New parcel models make deliveries quicker and more flexible. Some companies use drones or same-day networks to get parcels to customers fast. Others offer door-to-door services that include customs and delivery fees in one package. These changes help brands keep up with high demand and make customers happier.

Logistics Management

Digital tools have changed how companies manage logistics. Automated systems connect with online shops and handle orders without people doing it by hand. Real-time tracking lets teams see where every parcel is, even on the busiest days. Cloud-based platforms help companies grow or shrink as needed, making Q4 easier to handle. By updating warehouse tech and working with many carriers, businesses stay flexible and keep costs down.

Using technology and new delivery models helps companies stay green and save money, even when Q4 is very busy.

Performance and Improvement

KPIs

Delivery Accuracy

Logistics teams check if deliveries are on time. They use the on-time delivery rate to see this. If this rate stays above 95%, customers are happy. People trust the service more when orders arrive as promised. Real-time tracking helps teams spot delays early. Smart route planning lets them fix problems fast.

Cost Efficiency

Cost efficiency is also very important. Teams look at cost per shipment and fuel use. They also check how well they use their vehicles. Tracking these numbers helps them save money. They might change routes to use less fuel. Sometimes, they combine shipments to fill trucks. Companies try to keep costs between $100 and $300 per shipment. They also watch fuel use and keep vehicles in good condition.

KPI Name | Definition | Advantages | Benchmark / Target | How to Improve / Notes |

|---|---|---|---|---|

On-Time Delivery Rate | Shipments delivered on or before scheduled time | Reliability, customer satisfaction | 95% or higher | Use real-time tracking, optimise routes |

Cost Per Shipment | Average cost per shipment | Pricing, cost control | $100–$300 | Track fuel, optimise routes, manage labour |

Fuel Efficiency | Fuel use per distance or shipment | Cost savings, sustainability | N/A | Monitor fuel, maintain vehicles |

Customer Satisfaction Score | Net Promoter Score (NPS) | Repeat business, retention | NPS above 50 | Collect feedback, improve service |

Vehicle Utilisation Rate | Fleet used for shipments vs. total fleet | Efficiency, less idle time | N/A | Schedule maintenance, optimise deployment |

Customer Retention Rate | Percentage of repeat customers | Loyalty, satisfaction | 95% or higher | Focus on service, timely delivery |

Customer Feedback

Collection Methods

Companies get feedback in different ways. They send surveys after deliveries. They ask for online reviews or call customers. Some use Net Promoter Score to check loyalty. Listening to feedback helps teams know what works. It also shows what needs fixing. Fast feedback lets them solve problems before customers get upset.

Service Enhancement

Feedback helps teams make service better. If returns are slow, they can speed up the process. If tracking is not clear, they can update their systems. Companies that act on feedback build trust. Customers come back when they feel heard. Teams also notice trends, like which items get returned most. They fix these issues quickly.

Tip: Teams should answer feedback fast and thank customers. This shows they care and want to get better.

Continuous Optimisation

Review Cycles

Continuous optimisation keeps logistics strong. Teams check KPIs every week or month. They look for patterns, like higher costs or late deliveries. If they spot problems, they change their plans. They also compare their numbers to industry standards. This helps them stay ahead and avoid surprises.

Market Adaptation

Markets can change quickly, especially in Q4. Teams watch for new rules or fuel price changes. They also track what customers want. AI tools help them spot trends and act fast. If a port is busy, they use another route. They put stock in the right places to cut shipping times. Quick changes help companies stay ahead and keep customers happy.

Move inventory across sales channels.

Match stock with big sales events.

Use local warehouses for faster delivery.

Make returns simple and quick.

Continuous improvement means listening, checking, and acting. Teams that do this well win in Q4 and after.

Future Trends

Emerging Tech

Blockchain

Blockchain is changing how companies handle cross-border logistics. This technology keeps a safe, shared record for every shipment. Everyone in the supply chain can see the same details. This makes mistakes and fraud less likely. Companies trust each other more because they can check every step. Blockchain also helps customs checks go faster. Paperwork moves quickly, so goods cross borders with fewer delays. Many logistics teams now use blockchain to track goods and prove where they come from.

Autonomous Vehicles

Autonomous vehicles are starting to be used in logistics. These include self-driving trucks and delivery drones. They help move goods fast, even when drivers are hard to find. Drones can bring small parcels right to customers’ doors. Self-driving trucks work all day and night, so shipping is quicker. Automation and robots in warehouses make picking and packing faster. Experts think more companies will use these tools in the next five years to save time and money.

Did you know?

Artificial Intelligence, automation, blockchain, and IoT will make cross-border logistics faster, cheaper, and more reliable. Companies in the US, Canada, and Mexico already use these technologies to work better and meet new sustainability goals.

Regulatory Shifts

Trade Agreements

Trade agreements decide how goods move across borders. New deals like USMCA and CPTPP set rules for tariffs, customs, and even data flows. These agreements can make trade easier but also add new rules to follow. Sometimes, they limit how countries protect consumer privacy. Companies must keep up with these changes to avoid fines and delays. Many now move supply chains to new countries, like from China to Mexico or Vietnam, to manage costs and risks.

Data Privacy

Data privacy laws are getting stricter. Some trade agreements treat privacy rules as trade barriers. This makes it hard for companies to follow both trade and privacy laws. Businesses must track where their data goes and who can see it. They often update their systems to meet new rules in each country. Privacy and legal teams work together to keep data safe and avoid trouble.

Companies must watch for new privacy laws in every market.

Moving data between countries means following many different rules.

Teams need to update data maps and check for risks often.

Consumer Behaviour

Personalisation

Customers want brands to know what they like. AI helps companies offer products and deals that match each shopper’s taste. Personalised recommendations lead to more sales and happier customers. Many shoppers now expect fast answers and tailored service. Automated customer support gives quick help, making people more likely to buy again.

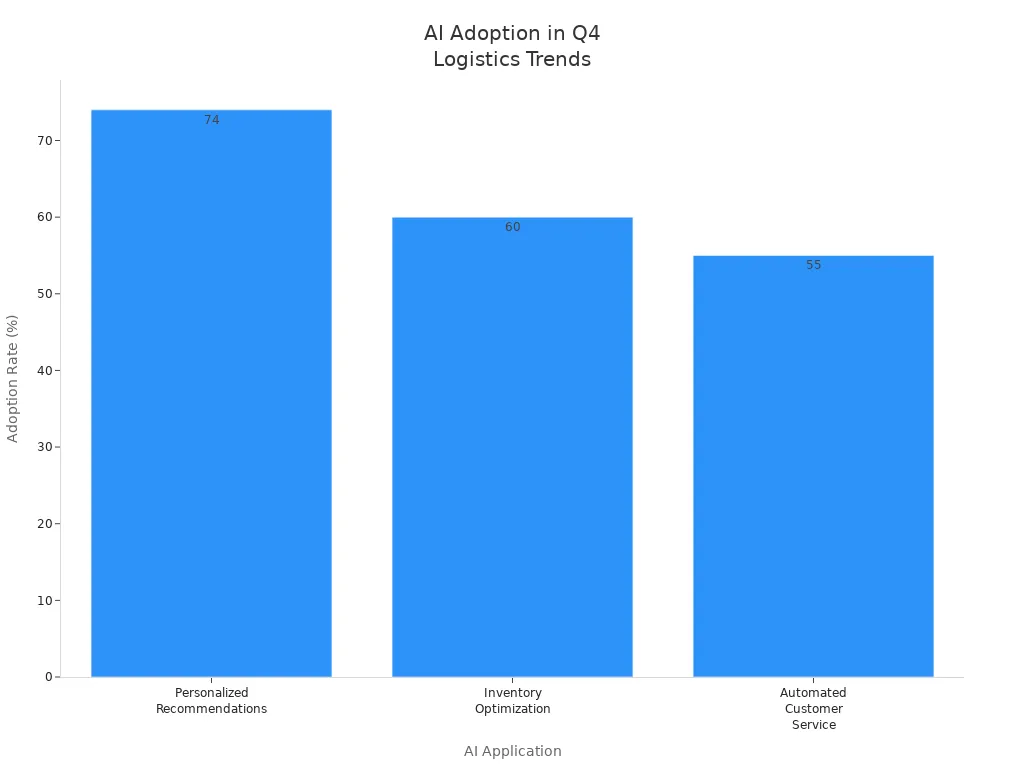

AI Application | Adoption Rate | Impact on Logistics and Customers |

|---|---|---|

Personalised Recommendations | 3x higher conversion rates, better inventory planning | |

Inventory Optimisation | 60% | 35% fewer stockouts, more accurate fulfilment |

Automated Customer Service | 55% | 20% faster responses, higher satisfaction |

Sustainability

Sustainability is more important than ever before. Over 70% of shoppers care about eco-friendly brands. Many will pay more for green products or carbon-neutral shipping. Some choose slower, greener delivery to help the planet. Companies now use recycled packaging and offer refurbished goods. In France, one in five people bought refurbished electronics last year. Brands that show real action on sustainability win trust and loyalty.

Companies that balance speed, personalisation, and sustainability will lead the way in Q4 cross-border logistics.

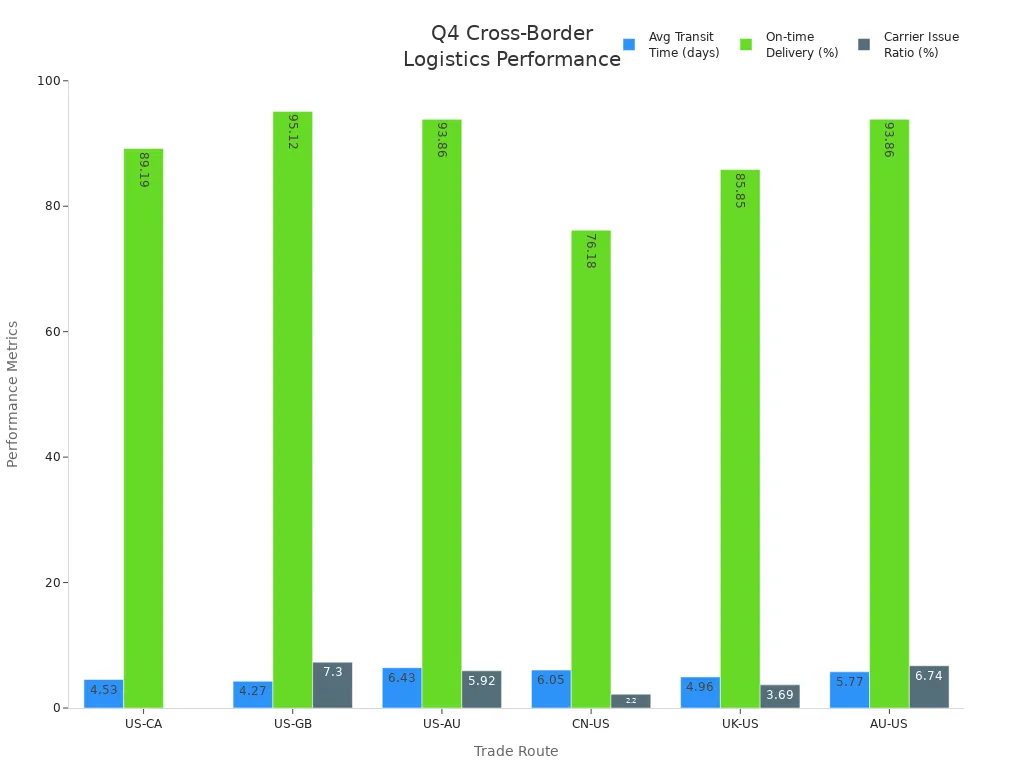

Logistics teams can get ready for Q4 by using new technology and automation. Working with good partners helps them do better. The table below shows how real-time tracking and customs efficiency help top trade routes. Flexible delivery choices make things easier for customers. Using eco-friendly packaging and saving money helps companies stay strong, even when tariffs go up. Teams should check how they are doing and talk often with their partners. They need to change quickly when new trends appear. Always trying to get better helps teams stay strong for busy times in the future.

FAQ

What is the best way to get ready for Q4 cross-border demand spikes?

Logistics teams should start planning early. They can put stock closer to buyers. Using more than one warehouse helps a lot. Good forecasting tools help teams guess what people will buy. This stops them from running out of products.

How does technology help cross-border logistics?

Technology gives live updates and helps teams track shipments. AI and automation make planning quicker. IoT devices show where goods are all the time. These tools help companies deliver on time and keep customers happy.

Why are certified carriers important in Q4?

Certified carriers follow strict rules. They use safe systems and get through customs faster. This means fewer delays and safer shipments. Teams trust these carriers when it gets busy.

How can companies make returns simpler for customers?

Companies can give local places for returns. They use clear steps and easy forms. Fast refunds help build trust. Simple returns make customers want to shop again.

What are some eco-friendly ways in logistics?

Use recycled or biodegradable packaging

Pick electric vehicles for deliveries

Plan routes to use less fuel

Eco-friendly actions help the planet and bring in more customers.

How do teams check logistics performance?

Teams watch key numbers like on-time delivery, cost per shipment, and customer happiness. They use these numbers to find problems and make service better.

KPI | What it Shows |

|---|---|

On-Time Delivery | Reliability |

Cost Per Shipment | Efficiency |

Customer Satisfaction | Service Quality |

What trends will change cross-border logistics in the future?

New tech like blockchain and autonomous vehicles will change how goods move. New trade rules and privacy laws will also affect logistics. Customers want faster, greener, and more personal service.

TangBuy: A Smarter Way to Dropship in 2025

If you're looking to stay competitive with dropshipping in 2025, speed and trend-awareness are key. TangBuy helps you stay ahead with real-time product trends, fast fulfilment, and factory-direct sourcing. With over 1 million ready-to-ship items, 24-hour order processing, and seamless Shopify integration, TangBuy makes it easier to test, scale, and succeed in today's fast-moving eCommerce landscape.

See Also

Effective Ways To Attract More Buyers To Your Store

BigCommerce Versus Shopify Comparison: Best eCommerce Platform 2025

Key Factors For eCommerce Success With BigCommerce Or Shopify

Essential eBay Dropshipping Advice To Boost Seller Success 2025