Speed, Service, Success: Optimizing Cross-Border Logistics in Q4

You feel a lot of stress in Q4. Cross-Border Logistics has more demand. The market changes fast. There is not much space for goods. Look at these real-world trends:

Spot rates in November went up 5% from last year. This is the biggest jump since early 2022.

Los Angeles and Long Beach ports will have delays over 10 days. Retailers rush to get inventory.

Tariff problems and missing drivers make space tighter. This makes shipping cost more.

If you use AI, automation, and data analytics, you can plan better. You can guess demand and plan routes. Regional warehouse optimization helps with returns. It also keeps customers happy. Advanced tools and flexible plans help you handle supply chain shocks. You can stay ahead.

Key Takeaways

Q4 has high demand and less space, so plan early. Use AI and forecasting tools to stop delays and empty shelves.

Labor shortages and customs changes make things hard. Use flexible staffing, automation, and strong partners to stay ahead.

Real-time tracking and automation make shipments faster. They help cut mistakes and build customer trust in busy times.

Dynamic routing and integrated systems lower costs and save fuel. They help more shipments arrive on time for smoother logistics.

Regional warehouses and smart returns management cut costs. They make refunds faster and help customers feel happy.

Eco-friendly packaging and green shipping make less waste. They lower carbon footprint and attract eco-friendly customers.

Pick partners with experience, local knowledge, and good technology. Make sure they have strong infrastructure for Q4 challenges.

Track key performance indicators and check results after Q4. This helps improve operations and get ready for future busy times.

Cross-Border Logistics Challenges

Demand and Capacity

Peak Season Volume

Every Q4, there is a big rush. Retailers want shelves full before holidays. Trucks and ships carry more goods than normal. Ports like Los Angeles and Long Beach get busy. You see delays and longer waits.

Retailers order more, so demand rises quickly.

Trucking companies feel pressure. Small carriers have trouble keeping up.

Big operators do better, but space is tight everywhere.

Smart forecasting tools help you guess demand. These tools help you plan inventory. AI can show trends and help you avoid empty shelves. Weather and strikes can change things fast. You need to be flexible.

Carrier Limits

Capacity is tested in Q4. Trucks fill up fast. Over 10,000 trucking companies left in early 2024. This makes it hard to find space for goods.

Labor shortages and higher costs make things worse.

Ports have bottlenecks and labor problems.

Shippers switch routes to avoid strikes, but this crowds other places.

Work with carriers who have strong networks. Big trucking companies can handle more demand. Always have backup plans. If one route is blocked, use another.

Labor Shortages

Seasonal Staffing

It is hard to find enough workers in Q4. Warehouses and trucking companies hurry to hire.

A study shows 37% of logistics groups have big labor shortages.

61% say they have transport problems because of not enough staff.

Warehouse work and transport planning are hurt the most.

You can use temporary workers to fill jobs. Some companies use robots to unload boxes faster. Automation helps when workers are hard to find.

Retention

Keeping good workers is also hard. Many want better pay and safer jobs.

The average age in warehousing and transport is over 45.

Workers want flexible hours and healthier places to work.

Labor shortages hurt customer service in 58% of companies.

Offer training and better benefits. If your team is happy, you avoid mistakes and delays. You also save money on hiring new people.

Regulations

Customs

Customs rules change a lot. You must follow new tariffs and paperwork. This slows shipments and costs more.

Tip: Always check product codes and proof of origin before shipping. Mistakes cause delays.

Talk with your logistics partners often. Share updates to avoid surprises at the border.

Trade Policies

Trade policies change quickly, especially on big routes like US-Canada, US-China, and US-UK.

Check contracts to lower risk.

Make sure customs paperwork is correct.

Talk with your team and clients to stop disputes.

Use simple customs steps if you can.

Plan for changes and have backup routes ready.

Stay alert. If you react fast to new rules, your Cross-Border Logistics will run smoothly.

Disruptions

Weather

Weather can change quickly and ruin plans. In Cross-Border Logistics, storms and floods can stop shipments. Wildfires also cause problems. When a hurricane hits the Gulf Coast, trucks and ships cannot move. Snow in the Midwest blocks roads. Ports close down. Roads are not safe for travel. Your goods may wait for days until things get better.

Natural disasters do more than slow things down. They can hurt cargo or make you change your route. Sometimes, you pay extra for last-minute changes. If you ship to Canada or Australia, weather changes fast. You need backup plans for these times. Try to watch weather patterns and talk with carriers often. This helps you react quickly and keep customers happy.

Geopolitics

Geopolitical events can cause even bigger problems than weather. Trade wars and new tariffs can change rules very fast. Political tensions can block routes or add new paperwork. Costs can go up overnight. For example, new trade policies made logistics costs rise by 13% from Q4 2023 to Q1 2024. Tariffs now make returns cost more because of re-import duties and fuel surcharges.

Here are some common disruptions you see in Q4:

Disruption Type | Description/Impact |

|---|---|

Delivery delays | 58% of shoppers leave brands after many delays |

On-time cargo schedules | Cargo ships are on time only 64% of trips |

Geopolitical shifts | Global supply chains change because of political problems |

Peak season surcharges | Shipping costs go up about 20% in Q4 |

Port congestion & blank sailings | These cause random transit times and more delays |

Natural disasters | These make supply chains and logistics harder |

You also face higher costs and fewer workers. There is pressure to deliver faster. Small logistics companies have trouble paying for automation. When ports are crowded or ships skip stops, transit times change a lot. You must stay flexible and ready to switch routes or carriers.

Tip: Watch global news and weather alerts closely. Fast action helps you avoid big losses and keeps your supply chain moving.

Technology Solutions

Cross-Border Logistics Technology

Real-Time Tracking

You want to know where your shipments are. Real-time tracking helps you do this. GPS, RFID, and IoT sensors send updates about your cargo. You get alerts if there is a problem. This could be a customs delay or a route change. These alerts help you act fast and stop bigger problems.

You can see live updates on your shipments.

Automated customs checks help you cross borders faster.

AI can guess delays and suggest new routes.

Alerts tell you about theft or route changes.

Centralized platforms show all your shipments together.

Predictive analytics help you plan for slowdowns.

Notifications tell you when you need to act.

API integration lets you track shipments on your phone.

Tip: Real-time tracking helps your customers trust you. They know when their package will come. You can fix problems before they get worse.

Automation

Automation changes how you handle Cross-Border Logistics. Robots and smart machines work in warehouses. They pick, pack, and ship orders faster than people. Automated systems make fewer mistakes. They keep things moving during busy times.

Automated Guided Vehicles move goods in the warehouse.

Automated Storage & Retrieval Systems organize inventory.

Goods-To-Person systems bring items to workers.

Route optimization software finds the best delivery paths.

Real-time GPS tracking keeps shipments on time.

Predictive analytics help you avoid delays.

AI-powered robots do the same tasks over and over.

Automation lowers costs and speeds up shipping. You spend less time on manual work. You have more time to help your customers.

AI and Forecasting

Predictive Tools

AI helps you see what will happen next. It looks at market trends, past sales, and seasons. You can guess demand and manage inventory better. AI also tells you when trucks or machines need repairs. This helps you avoid breakdowns.

AI studies sales data to guess demand.

It helps you avoid running out of stock.

Predictive analytics show when you need more staff.

AI-powered tracking gives accurate delivery times.

Predictive maintenance keeps your trucks working.

Dynamic pricing changes costs when demand changes.

Companies like DHL and UPS use AI to save money. They also keep customers happy. You can do this too.

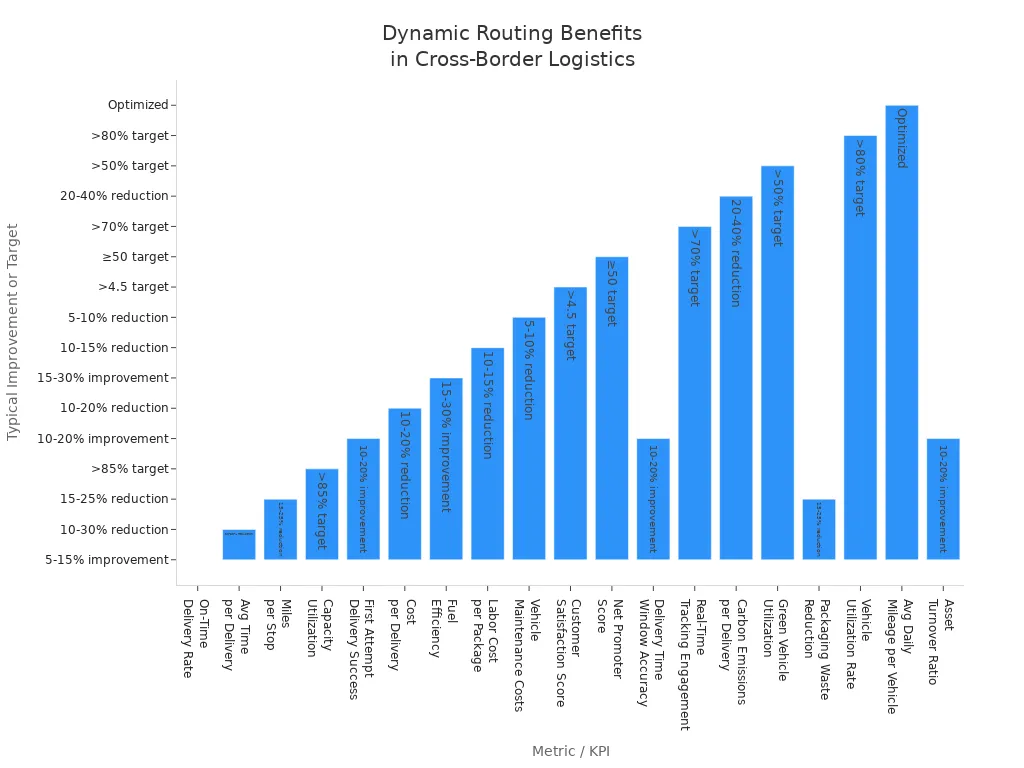

Dynamic Routing

Dynamic routing uses real-time data to find the best way. It checks traffic, weather, and fuel costs. You get faster deliveries and lower costs. AI can change routes if something goes wrong.

Real-time data helps you avoid traffic jams.

You pick the best carriers for each shipment.

You can manage more shipments with the same trucks.

Predictable lead times help you keep less safety stock.

Proactive planning makes your supply chain stronger.

Efficient routing lowers your carbon footprint.

Here’s a table that shows how dynamic routing helps your logistics:

Benefit Category | Metric / KPI | Description | Typical Improvement / Target Range |

|---|---|---|---|

Operational Efficiency | On-Time Delivery Rate (OTD) | % of deliveries within promised time window | Improvement of 5-15%, target >98% |

Average Time per Delivery | Mean time to complete a delivery | Reduction of 10-30% | |

Miles per Stop | Average distance between stops | Reduction of 15-25% | |

Capacity Utilization | % of vehicle capacity used | Target >85% | |

Cost Efficiency | Cost per Delivery | Operational cost per delivery | Reduction of 10-20% |

Fuel Efficiency | Miles per gallon of fuel | Improvement of 15-30% | |

Customer Satisfaction | Customer Satisfaction Score | Average customer rating (out of 5) | Target >4.5 |

Delivery Time Window Accuracy | % of deliveries within promised window | Improvement of 10-20%, target >95% | |

Environmental Impact | Carbon Emissions per Delivery | Average CO2 emissions per package | Reduction of 20-40% |

You get faster deliveries, lower costs, and happier customers. Dynamic routing also helps you use less fuel and packaging.

Note: Technology like cloud computing, IoT, and mobile apps help you pick, pack, and ship orders fast. You get better data and make decisions quickly. This makes your operations smoother.

Operational Efficiency

Integrated Systems

ERP/TMS

You want your logistics to work well. ERP and TMS help make this happen. These systems connect your supply chain from start to finish. You can see what is happening at every step.

Automation saves you a lot of time, up to 90%.

You spend about 25% less on operations.

Delays go down by 30%. Shipping costs drop by 15%.

These systems work with many shipping lines, so you can use different transport easily.

ERP and TMS let you find problems early. You get updates right away and can fix things fast. Automation keeps your data right and your team focused. You make better choices and keep things running, even when it gets busy.

Data Sharing

Sharing data helps everyone work together. When all teams use the same system, there are fewer mistakes. You can track shipments and plan routes in one place. This helps you react quickly if something changes. The system also updates you about rules, so you stay on track. Good data sharing helps your business grow.

Flexible Labor

On-Demand Staffing

Q4 can bring surprises. Sometimes you need more workers fast. On-demand staffing lets you add help when you need it. You can change your team size for busy days or sudden changes. This keeps your business running, even if things shift quickly.

Cross-Training

Cross-training means workers learn more than one job. You can move people where they are needed most. This helps with rush orders and covers when someone is out. Flexible labor lets you react fast to customer needs and changes. Your team can handle new routes or delays.

Tip: Flexible labor helps you deal with problems. You can change plans quickly, like many did during the pandemic.

Regional Warehouses

Returns Processing

Regional warehouses make returns simple and cheap. Local hubs mean customers do not ship items far. This lowers return shipping costs and gets products back faster. You can check, fix, and restock items quickly. This helps you not miss out on sales.

Customer Experience

Customers like fast, easy returns. Regional warehouses let you offer local returns and quick refunds. This builds trust and keeps shoppers coming back. There is less risk of lost or broken items. Your support team gets fewer questions, and customers stay happy.

When you use smart systems, flexible teams, and local warehouses, you work better and keep customers happy. That is how you succeed in Q4.

Sustainability and Returns

Eco Packaging

Recyclable Materials

Choosing the right packaging helps the environment. Recyclable materials support a circular economy. Boxes and fillers that can be recycled make less waste. Some companies use packaging made from ocean-bound plastics. These plastics are collected near the ocean, so they help keep water clean. Plant-based plastics come from cornstarch or sugarcane. They lower your carbon footprint. Mushroom packaging is made from farm waste and mycelium. It breaks down in less than two months!

Biodegradable materials break down on their own. This keeps landfills smaller.

Recyclable packaging lets you reuse and recycle. This helps the planet.

Eco-friendly fillers like shredded paper or cornstarch peanuts replace plastic.

Mushroom packaging and plant-based plastics are safe for nature.

Ocean-bound plastics stop pollution and make strong packaging.

Tip: Always check if your packaging follows shipping rules. This helps your packages move easily across borders.

Size Optimization

Using the right size packaging saves space and money. You use less material and fit more packages on trucks or ships. This means fewer trips and lower shipping costs. Protective materials keep products safe in smaller boxes. When you pick the best size, you lower the risk of damage.

Returns Management

Reverse Logistics

Returns are important in cross-border logistics. Regional return hubs make returns faster and cheaper. These hubs collect, sort, and process returns close to customers. AI-driven routing finds the best way to move returned goods. This can cut transportation emissions by up to 40%. You help the planet by reselling, repairing, or recycling returned items instead of sending them to landfills.

Cost Reduction

Smart returns management saves money. Consolidation centers combine returns from many customers into one shipment. This lowers shipping and processing costs. Automated return portals make it easy for customers to send items back. Green returns policies, like rewards for eco-friendly choices, attract more shoppers. In fact, 66% of people say they like brands with sustainable return options.

Note: Sustainable returns help with ESG reporting. You can show real numbers for emissions reductions and attract eco-conscious buyers.

Green Shipping

Carbon Footprint

You can lower your carbon footprint by picking green shipping. Many logistics companies offer carbon-neutral shipping. They use renewable energy or plant trees to offset emissions. Using alternative fuels like LNG or biofuels also helps cut pollution.

Consolidation

Consolidation is a smart way to ship more with less. You group shipments together so trucks and ships run full. This means fewer trips and saves fuel. It also lowers emissions and costs for you.

Carbon-offset programs help balance shipment emissions.

Sustainable packaging and alternative fuels are popular now.

Grouping shipments cuts waste and supports a greener supply chain.

Customers notice when you choose green shipping. You build trust and stand out in a busy market.

Partner Selection

Picking the right logistics partner is very important for Q4. You need someone who understands busy times and can handle surprises. They should keep your shipments moving, even when things get tough. Let’s see what you should look for when choosing a partner.

Experience

Q4 Track Record

Your partner should have a good record in Q4. Ask them for proof they did well before. Did they deliver on time last year? Can they handle big jumps in demand? Good partners set clear goals before the season starts. They plan how goods and data will move so you know what will happen.

Here’s a checklist to help you check their experience:

Make sure their skills fit your needs.

Set clear goals and ways to measure success.

Find partners who fill gaps in your logistics.

Check what technology they use.

Compare different ways to outsource.

See if they know your industry and have good solutions.

Use a scorecard to rate each provider.

Share your past data and what you expect.

Ask for references from other customers.

Think about what you might need in the future.

Tip: Pick carriers who have worked in cross-border logistics for a long time, like J.B. Hunt or Landstar. Trusted programs such as FAST can help your shipments cross borders faster.

Regulatory Knowledge

Your partner must know the rules for shipping. Customs paperwork changes a lot. Mistakes can slow down your shipments or cost you money. Choose a team that keeps up with trade laws and knows how to avoid problems. They should help you finish paperwork before your goods reach the border. Partners who know the rules well keep your shipments moving and protect you from surprises.

Infrastructure

Technology

Good technology helps your supply chain work better. You want partners who use digital tools for planning routes and managing warehouses. Real-time tracking lets you see your shipments at any time. AI and machine learning help guess demand and pick the best delivery routes. These tools make your logistics faster and more accurate.

Automated warehouses help fill orders faster.

New ideas like drone delivery and micro-fulfillment centers help during busy times.

Warehousing

Smart warehousing helps you manage your inventory. Partners with local warehouses can handle returns quickly and keep products close to customers. Early demand forecasting and strong warehousing help you avoid running out of stock and keep up with Q4 demand.

Local Expertise

In-Country Teams

Local experts know the area well. They help you follow changing rules and customs. Customs brokers and local teams make sure your paperwork is correct. They help your shipments cross borders without problems. They know the best routes and can spot risks early.

Multilingual Service

You want a partner who speaks the local language. Teams who speak many languages help you talk to customs, drivers, and warehouse workers. This stops confusion and helps fix problems faster. Local knowledge helps you plan routes, avoid tolls, and handle safety risks.

When you pick partners with experience, good infrastructure, and local knowledge, your Q4 shipments are more reliable. You can avoid problems and keep your customers happy.

Regional Strategies

US-Canada

Customs

Shipping between the US and Canada can feel tricky, especially in Q4. You face more paperwork, new tariffs, and changing rules. Customs delays can slow down your shipments. To keep things moving, you should:

Use technology like AI and IoT for real-time tracking and automated customs forms.

Work with experienced customs brokers who know the latest rules.

Stay updated on seasonal changes, like winter weather or spring road limits.

Plan for extra checks during busy times.

You can also use blockchain to keep your data safe and make sure your documents are correct. Good communication with your partners helps you solve problems fast. If you keep everyone in the loop, you avoid surprises at the border.

Warehousing

Warehousing near the border helps you move goods faster. Regional warehouses let you store products close to your Canadian customers. This means you can ship orders quickly and handle returns without long delays. You should:

Invest in local warehouses to cut lead times.

Use electric vehicles and renewable energy to meet green goals.

Try nearshoring to keep your supply chain flexible.

Use real-time data to track inventory and shipments.

When you use smart warehousing and strong partnerships, you save money and keep customers happy. You also lower your carbon footprint and meet new regulations.

US-China

Trade Policies

Trade between the US and China changes fast. New tariffs and rules can pop up in Q4. For example, the US removed the de minimis exemption for Chinese goods. Now, all shipments must go through full customs checks and pay tariffs. This makes shipping slower and more expensive. You might see:

Higher costs for customs processing and filing.

More paperwork for each shipment.

Sudden changes in shipping demand as companies rush to beat new tariffs.

You need to watch for policy updates and plan ahead. Some companies ship early to avoid new fees. Others look for new suppliers outside China to lower risk.

Shipping Modes

Shipping modes matter a lot in Q4. Air cargo used to be popular for fast e-commerce orders from China. Now, with higher tariffs and more customs checks, air cargo volumes are dropping. Ocean freight becomes more important, but it can get crowded when everyone ships at once. Here’s what you can do:

Mix shipping modes to balance speed and cost.

Use predictive analytics to choose the best route.

Watch for changes in ocean and air rates after new tariffs.

If you stay flexible and use data to guide your choices, you can avoid delays and control costs.

US-UK/Australia

Distribution

Shipping to the UK or Australia means you need smart distribution. Regional warehouses or distribution centers help you keep products close to your customers. This cuts down on shipping time and costs. You should:

Use local warehouses to control inventory and speed up fulfillment.

Work with 3PLs for real-time updates and tracking.

Keep in touch with your partners to fix problems fast.

A good distribution plan helps you avoid stockouts and keeps your customers happy.

Returns

Returns can get complicated in cross-border shipping. You want to make it easy for your customers and save money at the same time. Here are some best practices:

Map out every step of the return process to spot slowdowns.

Use a central system to track all returns and find ways to improve.

Automate returns with platforms like ReturnBear or Loop Returns.

Offer exchanges or store credits to keep more revenue.

Set up local drop-off spots for easy returns.

Combine returns into fewer shipments to cut costs and help the environment.

Watch for fraud or abuse to protect your business.

If you follow these steps, you make returns simple and keep your customers coming back.

LATAM Expansion

Expanding your cross-border logistics into Latin America (LATAM) can open up new markets and boost your business. But you will face some unique challenges and exciting opportunities. Let’s look at what you need to know about freight costs and delivery times in this fast-changing region.

Freight Costs

Freight costs in LATAM can swing up and down. You might see lower rates when there is extra space on container ships. But sometimes, costs jump because of port congestion or old equipment. Here are some things that can affect your shipping bills:

Many LATAM ports have shallow water and old cranes. This means big ships cannot dock, so you pay more for smaller ships or extra transfers.

Landside congestion slows down trucks and trains. When ports get crowded, you wait longer and pay more for storage.

Some ports do not have enough feeder ships. If your cargo needs to move from a small port to a big one, you might pay extra for that service.

Managing paperwork in different languages can lead to mistakes. Customs delays can add surprise fees.

But you also have new ways to save money:

The Panama Canal now lets bigger ships pass through. This means you can use new routes and maybe pay less per container.

Shipping lines are adding more ships. In 2024, there is 10% more space, and another 6% is coming in 2025. More space can mean better rates for you.

New alliances, like the Gemini alliance, use hub-and-spoke models. They aim for 90% efficiency, which can lower your costs.

Tip: Work with partners who know the local market. They can help you pick the best routes and avoid hidden fees.

Delivery Times

Customers in LATAM want their orders fast, just like everywhere else. But delivery times can be tricky. Here’s why:

Ports may get backed up because of old equipment or not enough space.

Local rules change often. If you miss a document or use the wrong language, your shipment can get stuck.

Roads and railways may not always connect well to ports. This can slow down your last-mile delivery.

You can speed things up by using smart tools:

Try multimodal transport. Combine trucks, ships, and even planes to find the fastest route.

Use real-time tracking with IoT sensors. You can see where your cargo is and fix problems before they get big.

AI can help you plan routes and avoid traffic or weather delays.

Digital platforms make it easier to manage paperwork and talk to your partners.

Here’s a quick look at what helps and what hurts delivery times:

Factor | Slows Down Delivery | Speeds Up Delivery |

|---|---|---|

Port congestion | ✅ | |

Old equipment | ✅ | |

Multimodal transport | ✅ | |

Real-time tracking | ✅ | |

Local expertise | ✅ |

Note: If you focus on technology and pick the right partners, you can cut delivery times and keep your customers happy—even in a complex region like LATAM.

Measuring Success

KPIs

Tracking the right KPIs helps you see if your cross-border logistics work well in Q4. You want to know what’s working and what needs to change. Here are some important KPIs you should watch:

On-time delivery

Inventory turnover

Return rate

Customer satisfaction scores

Cost per mile (CPM)

OTIF (On-Time In Full)

Load-to-truck ratio

Spot vs. contract rate spread

These numbers show how fast and reliable your service is. They also help you spot problems early and make smart decisions.

Delivery Speed

Delivery speed matters most during Q4. Customers want their orders fast, especially for holidays. You should check your on-time delivery rate and OTIF. If you see delays, look at your routes and carriers. Fast delivery keeps your customers happy and builds trust.

Customer Satisfaction

Customer satisfaction scores tell you how well you meet expectations. You can use surveys or reviews to get feedback. High scores mean your process works. Low scores show you where to improve. Happy customers come back and tell others about your service.

Feedback

Post-Q4 Review

After Q4 ends, take time to review your performance. Meet with your team and partners. Look at your KPIs and talk about what went well and what did not. This is your chance to find bottlenecks and fix them before the next busy season. Open talks with your 3PL partners help you solve problems together and adjust to new market changes.

Lessons Learned

Use the quiet months, like August, to dig into your returns process and refund speeds. Small changes, such as auto-routing returns to the nearest hub or speeding up refunds, can make a big difference. Set clear targets for return rates and refund timing. Train your staff and work closely with your partners. These steps help you avoid surprises and keep improving every year.

Note: Technology that automates order routing, shipping, and tracking makes it easier to spot issues and fix them fast. This keeps your logistics strong for the next Q4.

Innovation

New Tech

Staying ahead means you need to try new things. Real-time tracking platforms let you see your shipments at every step. Predictive analytics help you plan for delays or disruptions. Sustainability tools help you cut waste and lower your carbon footprint. Expanding your warehouse network supports nearshoring and faster delivery.

Training

Technology is great, but your people matter too. Keep your team trained on new systems and best practices. When your staff knows how to use new tools, you get better results. Mixing human expertise with smart tech helps you handle complex cross-border shipments with confidence.

Embracing innovation and learning from each season keeps you ready for anything. That’s how you stay ahead in cross-border logistics.

If you make your logistics better for Q4, you will deliver faster. You also spend less money and make your customers happier. Here are some things you get:

AI-driven load planning and automation help you save up to 12%. They also make orders move faster.

Keeping inventory close and picking smart carriers helps you deliver on time.

Real-time analytics let you spot problems early and keep service good.

Using green packaging and better routes saves money and helps the earth.

Keep trying new ideas, stay ready for changes, and work well with partners. Use technology, local plans, and data to help your business win all year.

FAQ

How can you speed up cross-border shipping in Q4?

Use real-time tracking to see where shipments are. Automation helps move orders faster. Pick warehouses near your customers. Work with partners who know busy times. Plan early and check for possible delays.

What technology helps you manage Q4 logistics?

AI and IoT sensors help you track shipments. Cloud platforms let you see updates fast. Warehouse robots pick and pack orders quickly. Automated systems make work easier and faster.

Why do you need local partners for cross-border logistics?

Local partners know the rules and speak the language. They help you avoid customs delays. They fix problems fast. You get better service and quicker deliveries.

How do you handle returns from other countries?

Set up return hubs close to customers. Use automated portals for easy returns. Combine shipments to save money. Give quick refunds to keep customers happy.

What makes packaging eco-friendly for cross-border shipping?

Eco-friendly packaging uses recyclable or biodegradable materials. Right-size boxes help cut waste. Ocean-bound plastics and plant-based fillers protect the planet.

How do you measure success in Q4 logistics?

Track KPIs like on-time delivery and order accuracy. Check customer satisfaction scores. Review feedback after Q4 ends. Use data to find problems and improve next time.

What should you look for in a logistics partner?

Check if they did well in past Q4s. Make sure they use smart technology. Look for strong local teams and good communication. Ask for references and compare their solutions.

Can you lower shipping costs during Q4?

Yes! Use consolidation to fill trucks and ships. Pick flexible routes to save money. Watch for special rates. Work with partners who know how to save during busy times.

TangBuy: A Smarter Way to Dropship in 2025

If you're looking to stay competitive with dropshipping in 2025, speed and trend-awareness are key. TangBuy helps you stay ahead with real-time product trends, fast fulfilment, and factory-direct sourcing. With over 1 million ready-to-ship items, 24-hour order processing, and seamless Shopify integration, TangBuy makes it easier to test, scale, and succeed in today's fast-moving eCommerce landscape.

See Also

Understanding The Real Expenses Of Dropshipping In 2025

Essential eBay Dropshipping Strategies For Sellers In 2025

Effective Ways To Attract More Shoppers To Your Store