The Power of Factory Data and its role in connecting to China’s best suppliers

You know it is important to find the right supplier in China. The Power of Factory Data helps you get ahead. It lets you see through the confusion and find real partners. Factories in China now use digital tools. These tools help them work better and make better products. You can see the change in many industries:

But you may still have problems like:

Communication barriers

Quality control issues

Cultural differences

Logistics headaches

Supplier reliability concerns

With good data, you can solve these problems. You can make better decisions.

Key Takeaways

Use factory data to find good suppliers in China. This data helps you choose with facts, not guesses.

Look at things like export volumes and transaction history. These show if a supplier is experienced and reliable.

Build trust by checking supplier records and customer reviews. Being open is important for good partnerships.

Always ask for quality reports and capacity details. This makes sure the supplier can meet your needs and keep high standards.

Find risks early by looking at factory data. Watch for signs like complaints about quality or changing prices.

Follow a clear process when you buy. Say what you need, talk to suppliers, and watch production closely.

Use digital tools to compare suppliers well. Software helps you track how they do and spot problems fast.

Keep learning about new digital trends in manufacturing. Using big data and automation can make your sourcing better.

Power of Factory Data

Business Impact

You want to find the best suppliers in China. The Power of Factory Data gives you the tools to do this. When you look at real data from factories, you can spot the suppliers who have strong experience and a good track record. You do not have to guess or rely on luck. You can use facts.

Let’s see how this works in practice. Here is a simple table that shows what you can learn from factory data:

Evidence Type | Description |

|---|---|

Key Exporters | You can see which companies export products often. This shows they have strong manufacturing skills. |

Export Volumes | High export numbers mean a supplier can handle big orders and has industry experience. |

Transaction History | A long export history shows a supplier is reliable. New suppliers may not have this. |

Multiple Buyers | Suppliers with many international clients are usually more flexible and experienced. |

When you use the Power of Factory Data, you can compare suppliers side by side. You can check their export volumes, see how many buyers they have, and look at their transaction history. This helps you avoid risky choices. You can pick suppliers who have proven they can deliver.

You also save time. Instead of endless emails and calls, you can use data to narrow down your options fast. You get a clear view of the market. This makes your sourcing process smoother and more efficient.

Trust and Transparency

Trust matters when you work with suppliers in another country. The Power of Factory Data helps you build this trust. You do not have to take a supplier’s word for it. You can check their records and see real feedback from other buyers.

Here are some ways factory data builds trust and transparency:

You get clear information about a supplier’s business practices.

You can see their transaction history and customer reviews.

Many platforms now use a ‘Verified Buyer’ system. This combines AI and manual checks to make sure suppliers are real and trustworthy.

You can check if a supplier has worked with many buyers from different countries.

You can see if they have passed social audits or hold important certifications.

Transparency is not just a trend. It is something buyers and consumers want. Did you know that 73% of Gen Z consumers prefer brands that are open about where and how they make products? Many people want to know the story behind what they buy. They even look for direct access to product origins.

When you use the Power of Factory Data, you give your business an edge. You can show your customers that you care about quality and honesty. You can also make better decisions and avoid surprises.

Tip: Always check for detailed supplier data before making a deal. This small step can save you from big problems later.

The Power of Factory Data is changing the way you connect with Chinese suppliers. It helps you find partners you can trust and makes your sourcing journey much easier.

What Is Factory Data

You may ask what factory data means. It is not just numbers or reports. Factory data shows how a supplier does their work. You can learn the story behind the products you buy. This information helps you make good choices and avoid problems.

Key Elements

When you check factory data, you find many important parts. Each part tells you something new about the supplier. Here is a simple table to show what is most important:

| Component --- | Description --- | | Quality --- | Checks if the supplier meets quality needs and gives proof about part quality and checks. --- | | Capacity --- | Shows the most the supplier can make and if they can fill your order. --- | | Risks --- | Looks at possible problems like running out of materials or not following rules. --- | | Costs --- | Looks at how prices are set and if they can last. --- | | Pricing --- | Compares supplier prices with others and checks if prices are fair or if there are hidden costs. --- |

You can also use these parts as a checklist:

Quality

Capacity

Risks

Costs

Pricing

Each part helps you answer a question. Does the supplier make good products? Can they fill your order? Are there any risks? Is the price fair? Factory data gives you all these answers.

Tip: Always ask for quality reports and details about capacity before you pick a supplier. These two things can save you time and money.

Why It Matters

Factory data is important because it gives you control. You do not have to guess or hope things go well. You can see real facts about each supplier. This is very important when you work with Chinese suppliers. The market changes quickly, and rules change too. You need to keep up.

Factory data helps you manage your supply chain. You can see where your products come from and how they are made. This is very important now, with new tariffs and ESG rules. Full material declarations show you every step in the process. You can spot risks early and fix problems before they get worse.

The Power of Factory Data helps you build strong links with suppliers. You know who you work with. You can trust their numbers and what they say. This makes your business safer and more steady.

If you want your business to grow, factory data is your best tool. It helps you pick the right partners, avoid problems, and keep your customers happy. You get the facts you need, just when you need them.

Types of Data

When you want to find good suppliers in China, you need to know which data is important. The right data helps you choose wisely and avoid mistakes that cost money. Let’s look at the main types of factory data you should check.

Certifications

Certifications show if a factory follows important rules. They help you see if a supplier cares about quality, safety, and doing the right thing. Many buyers from other countries look for certain certificates before they trust a factory.

Here’s a simple table with common certifications you might find:

Certification Name | Description |

|---|---|

CE Certificate of Compliance | Lets products be sold in the EU. It means they are safe and healthy. |

RoHS Certification | Stops some dangerous things in electronics. It helps keep people and the planet safe. |

ISO 9001 | Shows the factory has good ways to manage quality. It means they want customers to be happy. |

CCC Certificate | Needed for things sold in China. It proves they follow local rules. |

HACCP Certificate | Makes sure food is made safely. |

Foreign Trade Registration Certificate | Needed for factories that import or export goods. |

ISO, CE

You will often see ISO 9001 and CE certificates. ISO 9001 means the factory has good ways to check quality. CE marking shows the product is safe for the EU. These two certificates mean the supplier cares about safety and quality.

Social Audits

Social audits check if a factory treats workers fairly and follows good rules. You might see certificates like WRAP or SEDEX. These show the factory cares about workers and safe places to work. Many buyers want these audits before they order a lot.

Tip: Always ask for proof of certifications. This step helps you avoid fake suppliers and keeps your business safe.

Capacity

Capacity tells you how much a factory can make. You want to know if a supplier can fill your order and deliver on time.

Technology

Factories with new machines and modern technology can make things faster and with fewer mistakes. You should ask what machines they use. This helps you see if they can do your job well.

Workforce

A skilled and steady workforce means better products and fewer delays. You can ask how many workers they have and if they are trained. If a factory has enough trained staff, they can finish your order on time.

Checking a supplier’s production capacity is important. You want to make sure they can give you what you need, when you need it.

Performance

Performance data shows how well a factory does its work. This is where you see if they keep their promises.

Quality Reports

Quality reports tell you if the factory meets rules like ISO 9001. You can also look for regular checks and outside inspectors. These reports show if the factory has strong ways to check quality.

Good factories keep defects low.

They check products at different times.

They often have outside experts check their work.

Delivery Stats

Delivery stats help you see if a supplier sends orders on time. You can look at how long it takes and how often they meet deadlines. Some factories even share data about temperature or other special needs.

Cycle time can drop by up to 30% with good systems.

Temperature uniformity (like ±0.5°C) matters for some products.

The Power of Factory Data brings all these facts together. When you use this data, you can compare suppliers, find the best ones, and build a supply chain you can trust.

Access and Use

Getting Data

You want to get the right factory data from Chinese suppliers. There are many ways to do this. You do not have to guess. Here are some simple steps you can try:

Ask for product samples. You can check if the quality is good.

Visit the supplier’s factory. You can see how they work and if they follow rules.

Use sourcing agents. They help you talk to suppliers and handle the process.

Send a sample from your batch for lab testing. This checks if the material is good.

Try supply chain mapping services. These show where your products come from.

Use blockchain technology. This lets you track your supply chain step by step.

Go for on-site visits. You can see things for yourself and spot problems early.

Tip: Always ask for proof and check details on your own. This helps you avoid problems and build trust with your supplier.

Tools

You have lots of tools to help you look at factory data and compare suppliers. These tools make your work easier and help you choose better. Here is a table with some popular choices:

| Software Name --- | Description --- | | FlexSim --- | Simulation tool for business problems. You can build models and see results clearly. --- | | NoMuda VisualFactory --- | Lean Manufacturing Software. It helps you work faster and shows real-time production. --- | | Maintainable Test --- | Web-based software for collecting and looking at test data from different places. --- | | Predator MDC --- | Real-time machine monitoring software. It collects and uses shop floor data. --- | | FactoryWorx --- | Advanced MES software with IoT and AI for digital factories. --- | | Bearex --- | Software for factory data analysis and supplier comparison. --- |

You can use these tools to check production data, watch machines, and compare suppliers. Some tools use AI to find patterns and help you decide faster.

Making Decisions

When you use factory data, you make better choices. You do not have to guess which supplier is best. Using data helps you pick suppliers who help your brand. Studies show that using supplier relationship models and value chain data helps you rate suppliers better. You get more correct results and avoid risky picks.

A new way to decide lets you score suppliers on speed, sustainability, and strength. You can see which supplier fits your needs best. This method uses different signs, so you get a full view.

Some models use advanced maths to deal with uncertainty. You can manage risks and keep your supply chain strong. When you use these ways, you save time and money. You also build a supply chain that can handle changes and surprises.

Note: Data-driven choices help you pick suppliers who match your business goals. You get better results and keep your customers happy.

Now you have the tools and steps you need. Use them to find the best suppliers in China and grow your business with confidence.

Reducing Risk

Spotting Issues

You want to avoid nasty surprises when you work with new suppliers. Factory data helps you spot problems before they grow. When you look at the right data, you can see warning signs early. Here are some common risks you might face when sourcing from Chinese factories:

Quality issues: If you see lots of complaints or returns, the factory might have deeper problems.

Lack of transparency: If a supplier hides their prices or will not let you visit, you should be careful.

Price instability: If prices change often without a good reason, your budget can suffer.

Legal risks: Sometimes, rules change fast. You might face legal trouble if you do not check the details.

You can use factory data to check for these risks. For example, you can look at a supplier’s quality reports, see their pricing history, and check if they let buyers visit. This helps you make safer choices.

Tip: Always ask for clear records and check if the supplier has a stable history. This small step can save you from big losses.

Case Studies

Let’s look at how factory data has helped real businesses. Imagine you run a small electronics brand. You want to find a new supplier for your headphones. You check two factories. The first one has lots of export records, steady prices, and good reviews. The second one has no export history and changes prices every month.

You pick the first factory. Your orders arrive on time, and your customers are happy. You avoid delays and save money. Another company did not check factory data. They picked a supplier with no records. Their products arrived late, and many items broke. They lost customers and had to start over.

You can see how using factory data helps you avoid mistakes. It gives you the facts you need to choose the right partner.

Quality Assurance

You want your products to meet high standards. Factory data makes this easier. Big data analytics let you see trends in production. You can spot problems before they reach your customers. Predictive quality analytics help you see if a factory might have issues soon, based on past data.

Some factories use digital twin technology. This means they can test changes in a virtual world before making them in real life. You get better products without extra costs. Real-time data integration lets you see what is happening in the factory right now. If something goes wrong, you can act fast.

Big data shows you patterns in quality.

Predictive analytics warn you about future problems.

Digital twins let you test ideas safely.

Real-time data helps you fix issues quickly.

Note: When you use factory data for quality checks, you protect your brand and keep your customers happy.

Factory data gives you the power to reduce risk, choose better suppliers, and keep your business strong.

Integration Steps

Process Guide

You want to make your sourcing process smooth and reliable. Factory data helps you do this. Here’s a simple step-by-step guide to help you use factory data in your workflow:

Define Your Product and Specifications

Decide what you need. Write down clear details about your product.Find Potential Agents

Search for agents who know the market and can help you talk to suppliers.Initial Inquiry and Communication

Send messages to suppliers. Ask questions about their products and services.Supplier Identification

Use factory data to check which suppliers match your needs.Quoting and Negotiation

Get price quotes. Compare them and talk about prices.Sample Approval

Ask for samples. Test them to see if they meet your standards.Order Placement

Place your order with the supplier you trust.Production Supervision & Quality Control

Watch the production process. Use data to check quality at every step.Logistics and Shipping

Plan how your products will get to you. Track shipments using data.Final Delivery and After-Sales

Check the final delivery. Use data to solve any problems after you receive your goods.

Tip: Always keep records of each step. This helps you spot problems early and fix them fast.

Best Practices

You want to get the most from factory data. Follow these best practices to make your supplier management strong:

Set clear goals and key performance indicators (KPIs).

Use one database to keep all supplier information in one place.

Improve how you check supplier risks.

Make your supplier onboarding process simple and strong.

Group your suppliers by type or size.

Use automation and self-service tools to save time.

Keep communication open and easy.

Check supplier performance often.

| Practice --- | Why It Helps --- | | Set KPIs --- | You measure success and spot problems quickly. --- | | Centralised Database --- | You find information fast and avoid mistakes. --- | | Regular Assessment --- | You keep your supply chain strong and reliable. --- |

Note: When you follow these steps, you build trust and keep your business safe.

Tangbuy Advantage

Tangbuy makes sourcing from China easier for you. You get more control and better prices. Here’s how Tangbuy helps:

You use a full-stack sourcing and fulfilment solution.

You can customise products with private labels or special packaging.

You get factory-direct prices, much lower than retail.

You choose flexible minimum order quantities to fit your needs.

You search and buy from over 300,000 products at factory prices.

You store your inventory for up to 90 days for free in Tangbuy’s China warehouse.

Want to build your own brand? Tangbuy lets you add your logo and design to products. You work directly with manufacturers, so you get exactly what you want.

With Tangbuy, you save money, avoid middlemen, and grow your business with confidence. You get the data, the tools, and the support you need—all in one place.

Digital Trends

Big Data

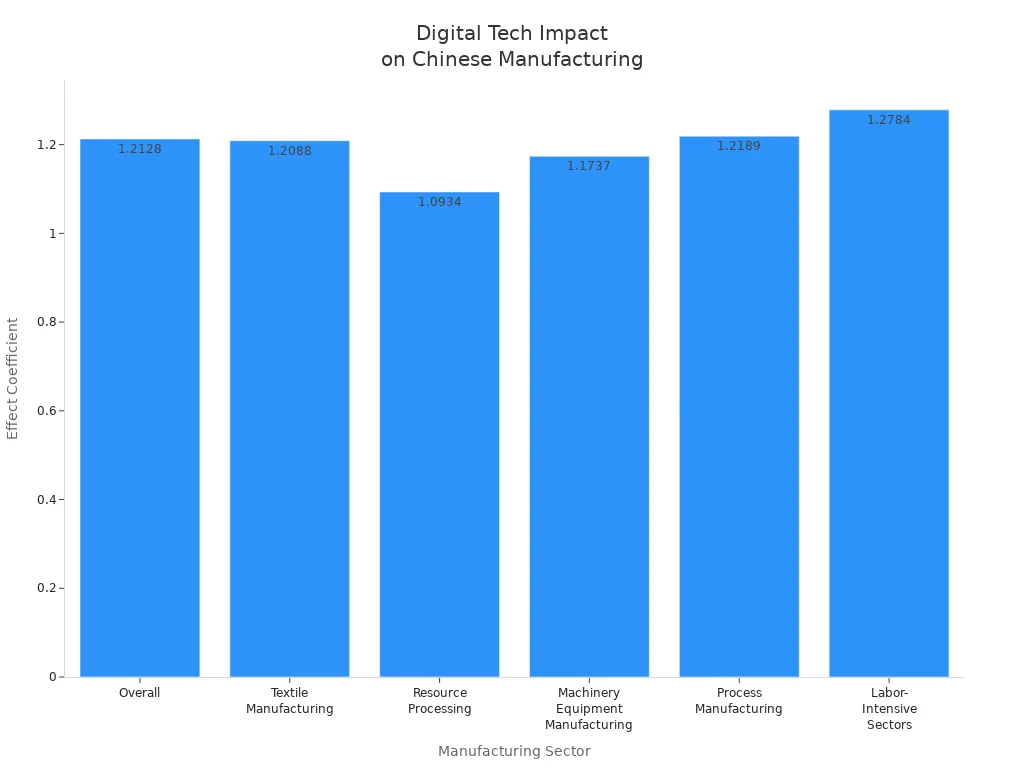

Big data is changing how factories work in China. More companies use digital tools to collect and study information. This helps them make better choices and improve products. From 2016 to 2021, high-end equipment makers in China raised their digital scores from 0.1215 to 0.1422. The growth is steady, but it is not very fast. Only a few companies have made quick progress. Government support helps the trend keep going up. When trade tensions happened in 2018, scores dropped for a short time. New policies helped factories get back on track.

Big data helps you spot patterns and problems early. You can see which suppliers do well and which ones need help. This makes your sourcing process smarter and safer.

Tip: Use digital dashboards to watch supplier performance and find issues before they get worse.

Automation

Factories in China now use more robots and smart machines than ever before. In 2023, over 270,000 industrial robots were installed. This is more than half of all new robots in the world. Automation helps factories work faster and with fewer mistakes. You do not need as many workers for simple jobs. Machines do the hard work, and people focus on planning and customer service.

Automation makes work faster and reduces mistakes.

AI helps managers and analysts understand complex data.

Many workers now move to service jobs as factories automate more tasks.

Automation fills labour gaps and keeps factories strong, even when some jobs move to other countries.

You get more reliable data from automated systems. This means you can trust the numbers when you choose suppliers.

Future Outlook

China wants to be a leader in technology and manufacturing. The country supports companies that want to be global champions. There is more investment in research and development, with R&D spending reaching 2.68% of GDP in 2024. China’s innovation ecosystem is strong, with many research centres, tech parks, and business clusters working together.

| Motivation --- | Description --- | | Global Champions --- | Support for Chinese companies to become leaders in the global market. --- | | High-Tech Leadership --- | Ambition to achieve leadership in high-tech sectors. --- | | Cyber Norms --- | Goal to spread China's cyber standards and norms internationally. --- |

When customers use digital tools, suppliers take more risks and try new ideas. This makes connections stronger and helps everyone grow. You also benefit from low manufacturing costs. China makes nearly 29% of the world’s goods, which keeps prices low for buyers everywhere.

If you understand the value chain in China, you can:

Handle sourcing challenges

Build strong links with manufacturers

Make smart choices about trends and costs

Improve your supply chain

Note: Keeping up with digital trends helps you find the best suppliers and keep your business ahead.

You can make better choices with factory data. Big data and machine learning help you choose good suppliers. These tools also help you lower risks. You get deliveries you can trust. Your supply chain becomes stronger. Here are some main benefits:

| Advantage --- | Description --- | | Proactive Procurement --- | You stay ready for changes. --- | | Informed Risk Mitigation --- | You spot problems early. --- | | Stronger Supplier Relationships --- | You work well with suppliers. --- | | Enhanced Demand Forecasting --- | You plan your orders better. --- |

Tangbuy lets you use dropshipping, private labelling, and custom packaging. You can build your brand and keep your customers pleased.

FAQ

What is factory data?

Factory data tells you how a supplier does their job. You learn about quality, capacity, costs, and risks. This helps you pick the best partner for your business.

How do I check if a Chinese supplier is reliable?

You can check export records, certifications, and reviews. Ask for samples and try to visit the factory. Good suppliers share clear data and answer your questions.

Why do certifications matter when sourcing from China?

Certifications show a factory follows safety and quality rules. You can trust suppliers with ISO, CE, or social audit certificates. These certificates mean they care about standards.

Can I use digital tools to compare suppliers?

Yes! You can use software like FlexSim or FactoryWorx. These tools help you track production and compare suppliers. You can spot problems early and make better choices.

How does factory data help me avoid risks?

Factory data helps you see warning signs. You can spot poor quality or unstable prices. You can act quickly and choose safer suppliers.

What is private labelling and how does Tangbuy help?

Private labelling lets you put your own brand on products. Tangbuy helps you customise packaging and add your logo. You work with manufacturers and save money.

Do I need to visit factories in person?

You do not always need to visit. You can use sourcing agents or ask for samples. Digital platforms let you check many things online. Visiting helps you see things yourself.

What if my supplier changes prices often?

Price changes can be a problem. You should check their pricing history and ask why. Good suppliers keep prices steady and explain any changes.

TangBuy: A Smarter Way to Dropship in 2025

If you're looking to stay competitive with dropshipping in 2025, speed and trend-awareness are key. TangBuy helps you stay ahead with real-time product trends, fast fulfilment, and factory-direct sourcing. With over 1 million ready-to-ship items, 24-hour order processing, and seamless Shopify integration, TangBuy makes it easier to test, scale, and succeed in today's fast-moving eCommerce landscape.

See Also

Maximising Profits by Sourcing Reliable Wholesale Party Supplies

Locating Dependable Wholesale Suppliers for Jeans in Your Business

Common Supplier Communication Errors and Their Solutions

Advantages of Dropshipping Stainless Steel Jewellery in 2025

Selecting Trustworthy Wholesale Suppliers for Affordable Bulk Footwear