Q4 Logistics Performance and Efficient Service Strategies for International Suppliers

International suppliers have hard decisions in Q4. They deal with not enough drivers, higher fuel prices, and not enough Full Truckload space. Companies that use AI for routing and real-time tracking can deliver faster and make customers happy. Planning ahead helps teams notice demand changes, get enough stock, and choose the best shipping routes. > Smart suppliers make good logistics partnerships and watch market signals, so they can avoid last-minute problems and keep Q4 Logistics Performance strong.

Key Takeaways

Start planning for Q4 early. Book shipping space soon. Get customs documents ready. Share sales forecasts to stop last-minute problems.

Use technology like AI and real-time tracking. Use automation to make deliveries faster. This helps lower costs. It also helps handle busy times well.

Work closely with logistics partners. Use connected systems to manage transport, warehousing, and inventory. This keeps things running smoothly when it gets busy.

Talk clearly with customers about shipping times. Tell them about any delays or return rules. This builds trust and keeps customers happy.

Train teams well on time management and packing. Teach them how to solve problems. This helps stop mistakes and makes Q4 less stressful.

Make backup plans for risks like bad weather or not enough workers. Plan for limits on how much you can ship. This keeps shipments moving without delays.

Make sure customs paperwork is correct and complete. This helps speed up border checks. It also stops fines or shipment holds.

Focus on green practices and what customers want. Use eco-friendly packaging and flexible work hours. Try local shipping for long-term success.

Q4 Logistics Challenges

Demand Surge

Every Q4, international suppliers get many more orders. This happens for a few reasons:

Some industries, like automotive and retail, have less inventory than before the pandemic. Even a small increase in demand can make companies rush to restock.

Back-to-school shopping and early holiday sales bring more buyers.

Some companies want to avoid new tariffs. They bring in extra stock, especially for apparel and toys. This can make imports go up by 30–90% compared to other years.

Changes in the economy, like higher wages and how much people can spend, also affect how much people buy in Q4.

Suppliers who want good Q4 Logistics Performance need to watch these trends. They can plan for more stock and avoid running out when demand goes up.

Supply Chain Disruptions

Q4 does not just mean more demand. It also brings more supply chain problems. Air cargo prices often rise before the holidays. For example, spot rates from Europe to North America went up 7% in one month, reaching $1.77 per kilogram. Routes from Southeast and Northeast Asia to North America went up by 6% and 4%. Outbound flights from Asia-Pacific to Europe and North America are 86-87% full, but return flights are less than 45% full. This shows there is not enough space going back.

E-commerce growth adds more pressure. In July, 37 million people downloaded the TEMU app. This made air cargo demand from China go up by 30%. Labor strikes can slow things down too. In early October, 39 container ships were set to arrive at the Port of New York/New Jersey. Strikes could make ships wait or change routes, risking billions in goods getting stuck. Inventory costs are also higher now, reaching the highest since early 2023. All these things make it harder for suppliers to keep goods moving.

Customs Complexities

Customs rules get harder every year, especially in Q4. Suppliers face some common problems:

Lower de minimis thresholds mean more paperwork and data, especially for direct-to-consumer shipments.

New tariffs on minerals, solar panels, and telecom gear raise costs and make it harder to find products.

Customs officers check for intellectual property rights and anti-dumping rules more often. This means more audits and cargo checks.

New rules need stricter product labels and proof of where goods come from.

The ACE 2.0 system needs real-time data sharing and better tech.

More audits and the 'Responsible Care' rule mean importers must prove their products are legal and their suppliers follow the rules.

These problems can slow down shipments, raise costs, and increase the chance of fines. Suppliers often work with customs brokers and use new technology to keep up with changing rules.

Capacity Limits

Capacity limits are a big problem for international suppliers in Q4. When more people order things, air and ocean freight space fills up quickly. Shippers try to book space, but there is not enough for everyone. This makes shipping prices go up. It also gets harder to find good service. Trucking companies do not have enough drivers. This means fewer trucks and more delays. Fuel costs keep going up, so moving goods costs more.

Ports get crowded. Ships wait longer to unload. Containers stack up at busy ports. Warehouses run out of room because companies store more for the holidays. These problems slow down the supply chain. Shipping lines sometimes skip trips or slow down ships to manage space. This makes it harder for suppliers to know when their goods will arrive.

Note: Holiday inventory buildup and more e-commerce make these problems worse. Suppliers face longer shipping times and higher costs. This can hurt Q4 Logistics Performance.

Suppliers can do a few things to handle these problems:

Book ocean and air freight space early, like 30 to 45 days ahead for ocean and 2 to 3 weeks for air.

Use different ports to skip the worst crowds.

Make contracts and ask for priority loading.

Build up inventory before the busy season starts.

Use real-time tracking to see delays and fix them fast.

Shipping lines also skip trips or change speeds to control space. Problems in other countries and new tariffs can make things even less certain. Suppliers who plan early and stay flexible can keep goods moving and control costs.

Customer Expectations

Customers want their orders fast and on time, even when it is busy. They want clear updates about when packages will come. If there are delays, they want honest answers. Many shoppers want simple and clear return rules. In fact, 71% of Nordic shoppers say clear return rules matter more than how long they have to return something.

Speed is important for returns too. Almost half of customers feel happy when they get refunds in less than three days. The best companies give refunds in just 48 hours. Central return hubs help make returns faster and cheaper for everyone.

Customers want their orders on time, even with driver shortages and delays.

Clear updates about delivery and returns help build trust.

Fast returns and refunds keep customers happy.

Companies can hire more workers or use third-party logistics to help during busy times.

Forecasting tools help suppliers get ready for more orders.

A flexible team helps companies handle more orders quickly. Well-trained workers keep things running and make fewer mistakes. Protecting the main team from burnout keeps quality high and orders moving. For example, one company got 28% more work done and cut labor costs by 15% during the busy season by using these ideas.

Meeting customer expectations is very important for good Q4 Logistics Performance. Suppliers who focus on speed, clear updates, and being reliable do better during the holidays.

Q4 Logistics Performance Strategies

Early Planning

Planning early helps suppliers do well in Q4. Many suppliers start getting ready in July or August. They talk to their logistics partners to get space and good deals. Sharing sales plans helps everyone get ready for busy times. Teams also finish customs forms and work with trusted partners to clear goods faster.

Here are some top ways to plan early:

Make shipping plans for busy times like delays and customs checks.

Get customs papers ready early and use trusted providers.

Use data to guess demand and track shipments live.

Build strong ties with 3PLs for extra help.

Suppliers also get ready before orders go up. They find backup couriers, plan for not enough drivers, and make delivery routes better. Having a backup plan helps if things go wrong, like driver holidays or not enough trucks. Many suppliers use 3PLs to get more trucks, space, and last-minute help.

Smart inventory planning is important. Teams match stock with sales channels and big sales days like Black Friday. Using Fulfillment by Amazon (FBA) can make deliveries faster and easier. Good updates and live tracking keep customers happy when it gets busy.

Tip: Planning early helps suppliers avoid mistakes like guessing wrong on warehouse space, using only one place, or waiting too long to move stock. It also stops last-minute problems and lost sales.

Integrated Logistics

Integrated logistics connects all parts of the supply chain. This helps suppliers handle Q4 rush and keep things smooth.

Transportation

Transportation is key for Q4 Logistics Performance. Suppliers use many carriers to get enough trucks, ships, and planes. They use tech to track shipments and change routes fast if needed. Integrated logistics providers, like 4PLs, link transport partners and use digital tools for live updates.

Suppliers book space early to avoid running out.

They use different routes and ports to skip busy spots.

Live tracking helps find delays and fix them fast.

Warehousing

Warehousing is hard in Q4. Suppliers run out of space as they store more for holidays. Integrated logistics links warehouses with transport and stock systems. This helps teams see what is in stock and where it is.

Suppliers do not guess wrong on warehouse space.

They use more than one warehouse to lower local risks.

Digital tools help manage space and speed up picking.

Inventory Control

Inventory control keeps products moving and customers happy. Integrated logistics uses tech to track stock across all sales channels. This stops too much or too little stock.

They use data to guess what will sell and when.

Automated systems update stock levels live.

Note: Integrated logistics makes orders faster, cuts costs, and helps suppliers grow in Q4. It also makes returns and reverse logistics easier.

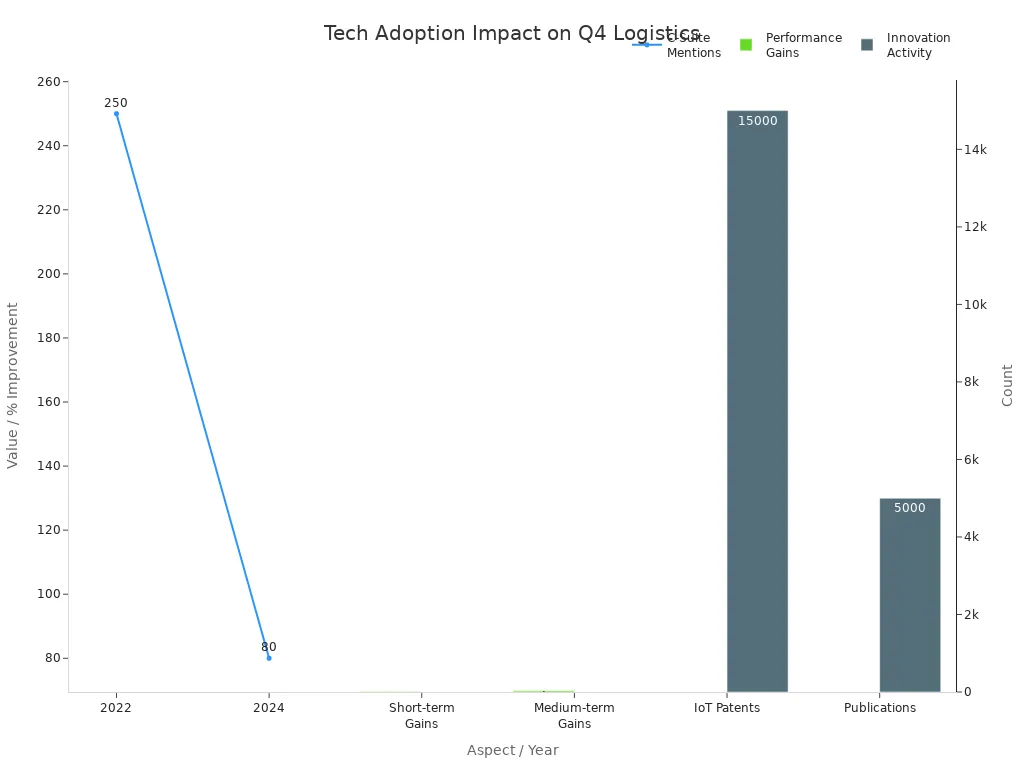

Technology Adoption

Technology is changing how suppliers manage Q4 Logistics Performance. Tools like AI, IoT, and automation make supply chains faster and smarter.

Real-Time Tracking

Real-time tracking gives instant updates on shipments. IoT sensors and GPS show where goods are at any time. This helps teams spot delays and fix problems early.

Real-time tracking makes things clearer.

It helps with fixing equipment and managing stock.

Suppliers can update customers fast if things change.

Data Analytics

Data analytics turns numbers into smart choices. Suppliers use analytics to guess demand, see trends, and plan for busy times. This helps stop running out of stock and keeps costs low.

Analytics tools help guess when demand will go up.

Teams use data to make delivery routes and warehouses better.

Suppliers see which products sell fast and change plans.

Automation & AI

Automation and AI do boring jobs and make supply chains work better. AI looks at lots of data and finds problems before they get big. Automation makes picking, packing, and shipping faster.

Automation cuts transport costs by 5%-10% and total logistics costs by 15%.

Unified AI platforms help suppliers make quick, smart choices.

Many companies see a 10% to 20% jump in transport and warehouse efficiency after using these tools. Over time, gains can reach 40%. Most supply chain leaders say AI and IoT make logistics more reliable and save money.

Cross-Border Shipping

Major Trade Routes

International suppliers have many problems when shipping in Q4. They need to pick the best carrier and route. This helps them deliver on time. Each shipping method works differently, especially during holidays.

Postal carriers like USPS or Hong Kong Post are slow. Packages stop at many places and go through customs. The last safe Christmas delivery is early, like December 1 from China to the US. Suppliers using postal carriers must ship much sooner to avoid late packages.

Express carriers such as UPS, FedEx, and DHL own their trucks and planes. They deliver packages faster and handle everything from start to finish. Their last safe Christmas delivery is later, around December 17-18 from China to the US. Express carriers help suppliers meet tight deadlines and keep customers happy.

Consolidators send many packages together and split them up later. They do not deliver inside the country. Their last safe Christmas delivery is between postal and express, often around December 5 from China to the US.

Suppliers who want good Q4 Logistics Performance should pick the right shipping for each order. They need to check shipping data, like postal codes and package sizes, before sending. Live inventory tools help teams see stock and make fast choices. Tech support and live shipping prices help suppliers handle changes and fix problems quickly.

Tip: Use automated returns to restock items fast and avoid slow communication. This keeps the supply chain moving and makes customers happy.

Customs Compliance

Customs rules change a lot, and Q4 brings more checks. Suppliers must follow each country’s rules to avoid delays and extra costs. Missing or wrong papers can stop shipments or cause long waits at the border.

Suppliers should keep up with trade rules and get help from experts if needed.

Using logistics software to fill out forms helps stop mistakes.

Seeing all inventory and warehouse info lets teams track orders and spot customs problems early.

Customs clearance needs the right papers, checks, paying duties, and release. Mistakes in papers can add days to delivery and cost more money. Real-time tracking helps suppliers find and fix problems before they get worse.

Note: Customs problems cause about 1.5 days of delay. Stopping paperwork mistakes saves money and keeps customers happy.

Accurate Documentation

Good paperwork is important for smooth international shipping in Q4. Suppliers who fill out forms carefully avoid delays, fines, and upset customers. Customs officers check every shipment for correct details. Missing or wrong papers can stop goods at the border.

Here are the main documents suppliers need and how they help:

Document Type | Purpose and Impact on Delays and Errors in Q4 International Logistics |

|---|---|

Customs Declaration | Describes goods for customs; correct forms stop delays, fines, and legal trouble. |

Certificate of Origin | Shows where products come from; right certificates help with tariffs and stop customs holds. |

Commercial Invoice | Lists goods, value, and terms; clear invoices help customs check shipments and speed things up. |

Bill of Lading | Proves who owns the freight and transport terms; correct bills stop fights and clearance problems. |

Packing List | Details amounts and weights; right lists help customs check shipments fast and avoid delays. |

Suppliers should use logistics software to make documents and stop mistakes. They need to check every form before shipping. Keeping up with new trade rules and working with experts helps keep papers right.

Customs delays often happen because of missing commercial invoices, bills of lading, or packing lists.

Real-time tracking and visibility tools help teams spot and fix paperwork problems early.

Good paperwork means faster customs checks, fewer shipment holds, and lower costs.

Tip: Good paperwork not only speeds up customs but also helps the rest of the supply chain. Suppliers who focus on paperwork have fewer delays and better Q4 Logistics Performance.

Service Efficiency Tactics

Customer Communication

Talking clearly with customers helps them feel calm in Q4. Many shoppers worry their packages will be late or lost. Suppliers who explain things early help everyone feel less stressed. They tell buyers how long orders take and if shipping might be slow. They also share the last day to order for holidays. This way, customers know what will happen and do not feel confused.

Suppliers use tools like automatic messages, live chat, and online accounts. These tools give real-time updates about orders and shipping. When customers get honest news, they trust the company more. Good updates mean fewer calls and emails, so teams save time.

Show real delivery times before people buy.

Give updates about orders and returns often.

Make return and stock rules easy to understand.

Telling customers about shipping deadlines and return rules helps everyone know what to expect. Suppliers who work with 3PLs can use their tracking and deadline info to keep buyers updated.

Some companies let customers pay for faster shipping. This gives people more choices and makes them happier during busy times. When suppliers talk well, they get fewer complaints and more repeat shoppers.

Returns Management

Returns go up in Q4, especially after big sales. Suppliers who handle returns fast keep customers coming back. They make return rules clear and the steps easy. Simple return instructions and quick refunds help people trust the company.

Many suppliers use big return centers to work faster. These centers sort and process returns quickly, so refunds come sooner. Some companies use machines to track returns and restock items fast. This keeps inventory healthy and cuts waste.

A good returns plan has:

Clear rules and steps for returns.

Fast refunds, usually in two days.

Automatic tracking for customers and workers.

Big centers to handle lots of returns.

Fast and easy returns make customers feel important. Suppliers who focus on returns see happier buyers and fewer bad reviews.

Supplier Collaboration

Working closely with partners makes Q4 logistics easier. When suppliers and partners team up, they can react fast to changes and avoid delays. Trust and sharing help everyone work better together.

Good teamwork means planning and guessing sales together. Suppliers and partners share sales guesses and stock numbers. This helps everyone get ready for busy times and avoid running out. Vendor-Managed Inventory lets suppliers control stock, which saves money and time.

Use tech tools to share data right away.

Set clear goals with written agreements.

Make deals to share risks if problems happen.

Digital tools help teams see how suppliers are doing and spot trends. Smart guessing tools help plan for busy times, so suppliers can change stock and shipping fast. Companies like Amazon and Toyota use these ideas to keep orders on time, even when it is busy.

Teamwork makes companies stronger. Suppliers who plan and share data together do better in Q4 and keep customers happy.

Team Training

Team training really helps in Q4 logistics. When teams know what to do, they work faster and make fewer mistakes. This keeps customers happy. Companies that spend time on training do better during busy months.

Smart companies start with a simple plan. They use clear steps like ADDIE to make training fit business needs. This way, everyone knows what will happen and why it is important. Blended learning is best. Teams learn in workshops, online classes, and by doing real tasks. This mix keeps learning fun and helps everyone learn in their own style.

Training should match the company’s culture and change when needed. When training feels useful, teams stay interested and work hard.

Many companies use online learning tools. These let workers learn anytime and check their progress. Some even use virtual reality to make lessons more real and fun. After training, managers see if it worked. They use models like Kirkpatrick’s to check if training helped teams do better.

Here are some ways companies make team training work for Q4 logistics:

Try training with a small group first. This helps find problems before everyone joins.

Tell teams why training matters. When people understand, they want to join in.

Share information in different ways. Some people like videos, others like reading or hands-on work.

Give help with mentors and regular check-ins. This keeps everyone moving forward.

Track who finishes training and how well they do. Use this to see what works best.

Ask for feedback right after training. Surveys and talks help find what to fix.

Update training often. Use feedback and results to make it better each time.

Teams need special skills for Q4. Companies teach delivery teams time management to speed up dispatch by 20%. Staff learn faster ways to pack and better routing. Training on new inventory systems helps everyone track stock. Some teams learn basic vehicle fixes to stop delays. Agile ideas help teams change plans fast. Double-checking before shipping stops mistakes.

Teach staff time management and packing.

Show efficient routing and scheduling.

Train on new inventory systems.

Practice basic vehicle fixes.

Use Agile ideas for quick problem-solving.

Help logistics and suppliers talk better.

Make double-checking before shipping a habit.

Well-trained teams handle Q4 stress with confidence. They work faster, solve problems quickly, and keep customers happy. Regular training keeps skills sharp and helps companies do well during the busiest season.

Risk Mitigation

Delay Prevention

Delays can mess up Q4 logistics for international suppliers. Many things cause delays, like bad weather or paperwork mistakes. Supply chain problems also slow things down. Suppliers need to plan ahead to avoid these issues. They check weather reports and make backup routes. Staff learn how to fill out documents the right way. Software helps catch errors before shipping starts.

Here’s a simple look at what causes Q4 delays and how to stop them:

Cause of Delay | Prevention Strategies |

|---|---|

Supply Chain Disruptions | Use more suppliers, keep extra inventory |

Weather Conditions | Watch forecasts, plan new routes, add extra time |

Traffic & Infrastructure | Pick better routes, check roads and bridges |

Customs & Documentation | Train staff, use special software |

Incorrect Address/Labels | Check labels twice, use tools to spot mistakes |

Peak Season Demand | Guess demand, plan space, use more carriers |

Mechanical Failures | Fix vehicles often, have backup trucks |

Labor Strikes/Shortages | Hire extra workers, work with more partners |

Carrier Capacity Constraints | Book early, plan loads carefully |

Last-Mile Delivery Issues | Plan routes well, talk clearly to customers |

Suppliers use real-time tracking to spot problems fast. Address tools help find mistakes before they get big. They tell customers about delays right away. This builds trust and keeps everyone calm.

Capacity Management

Q4 means lots of orders come in fast. Suppliers must manage space and workers so nothing runs out. The best teams use flexible workers. They hire more people when orders go up. When things slow down, they use fewer workers. This saves money and keeps service good.

Smart warehouse systems help teams work faster. These systems track stock and orders live. Barcode scanners and pallet trackers cut mistakes. Central ERP systems show all inventory and help teams plan.

Use many skilled workers to handle busy times.

Train your own teams instead of outsourcing.

Track inventory and orders with live systems.

Try warehouse tricks like wave picking and barcode scanning.

Teams that plan early and use tech can handle Q4 rush without problems.

Contingency Plans

No one can guess every problem, but backup plans help teams stay ready. The best teams list all risks, like not enough staff or bad weather. They make backup plans for each risk. For example, they hire extra workers or book more warehouse space. They also make deals with backup carriers.

Here’s an easy plan for Q4 problems:

List every risk, like weather or not enough workers.

Make backup plans, like extra staff or new routes.

Pick carriers that do a good job.

Use different shipping methods and partners.

Plan early and set clear deadlines.

Update plans often and check them.

Use tech for quick updates and fast choices.

Add extra hours or try cross-docking for flexibility.

Tell customers and partners about changes quickly.

Get ready for returns after big sales.

Suppliers map their supply chains and check partners for weak spots. They use smart tools to see risks early and act fast. Flexible supply chains work better than just adding backups. Teams that practice these steps stay calm and keep goods moving, even when Q4 gets busy.

A strong risk plan means fewer surprises and happier customers during the busiest season.

Q4 Logistics Performance Trends

Technology Trends

Technology is changing how companies do logistics in Q4. Many top companies use AI to plan the best delivery routes. This saves time and money. Predictive analytics helps teams know what customers will buy. This stops them from running out of stock. Warehouse automation makes picking and packing faster. Companies like Amazon, UPS, and DHL use these tools to deliver more orders on time. They can also react fast when lots of orders come in.

Blockchain is helping too. Platforms like TradeLens let suppliers share info safely. This builds trust and means less paperwork. In 2024, more companies use electric and hydrogen trucks. These trucks help lower pollution and follow green rules. Digital freight platforms help fill trucks better and stop empty trips. All these changes make Q4 Logistics Performance stronger and more reliable.

Sustainable Logistics

Sustainability is important in logistics, even in busy Q4. Companies use flexible work hours to keep workers healthy. They give wellness programs, snacks, and good chairs for long shifts. Teams try to stop burnout and fix labor shortages.

Many suppliers use green packaging to impress customers. They make shipments and boxes the same size to save space and cut waste. Digital tools help teams handle sudden changes in orders. By thinking about the planet, people, and money, companies build supply chains that last through Q4.

Digital tools for strong supply chains

Customer-Centric Models

Customer needs change how companies plan Q4 logistics. AI and automation help teams keep products in stock. Big data helps companies see what customers want. Real-time tracking and blockchain give customers updates and build trust.

Some companies make products closer to customers. This makes shipping faster and more reliable. Changing shipping prices helps companies manage costs when things change. Q4 Logistics shows that custom supply chain plans and regular checks help suppliers meet customer needs, even when it is busy.

Real-time tracking for supply chains

Local manufacturing for faster shipping

Flexible shipping prices to control costs

Companies that use technology, care about the planet, and focus on customers will do best in Q4 Logistics Performance in the next few years.

Companies that want good Q4 Logistics Performance plan early. They use smart technology to help them. Flexible warehousing helps during busy times. Clear communication keeps everyone on the same page. Automation makes work faster and easier. Teams work with partners to avoid mistakes. They train staff so fewer errors happen. Using new trends like AI and digital tools helps suppliers stay ahead. Apple shows that being creative and strong makes supply chains better.

Winning in Q4 means learning, getting better, and being ready for change.

Smart warehousing saves money and makes delivery faster.

Flexible partners and good workforce plans help companies grow.

Technology helps teams see what is happening and keeps customers happy.

FAQ

What is the best way to prepare for Q4 logistics challenges?

Suppliers need to start planning early. They talk with their partners first. They look at demand forecasts and book shipping space soon. Early planning helps stop last-minute problems. This keeps orders moving without delays.

How can suppliers handle sudden demand spikes during Q4?

They use real-time data to watch sales and inventory. Flexible teams help manage extra orders. Backup carriers are ready to help too. Quick choices keep customers happy when demand goes up.

Why does accurate documentation matter in international shipping?

Correct paperwork makes customs checks faster. It stops delays, fines, and lost shipments. Suppliers who check documents twice have fewer border problems.

What technology helps improve Q4 logistics performance?

AI, automation, and real-time tracking tools help teams work faster. These tools show where shipments are at all times. Teams can fix problems before they get bigger.

How do suppliers manage returns during the holiday season?

They make return rules clear and use big return centers. Fast refunds and easy steps help customers trust the company. Automation helps process returns quickly and smoothly.

What should suppliers do if a shipment gets delayed?

They tell customers right away about the delay. Teams check tracking tools and talk to carriers for answers. Honest updates help build trust and lower stress for everyone.

How can suppliers lower logistics costs in Q4?

They use data to plan the best routes and pick good carriers. Smart warehousing and automation help cut waste. Planning early helps avoid high last-minute shipping costs.

What trends will shape Q4 logistics in the future?

Suppliers will use more AI, green trucks, and digital tools. They will focus on fast delivery, clear updates, and eco-friendly packaging. These trends help meet customer needs and protect the planet.

TangBuy: A Smarter Way to Dropship in 2025

If you're looking to stay competitive with dropshipping in 2025, speed and trend-awareness are key. TangBuy helps you stay ahead with real-time product trends, fast fulfilment, and factory-direct sourcing. With over 1 million ready-to-ship items, 24-hour order processing, and seamless Shopify integration, TangBuy makes it easier to test, scale, and succeed in today's fast-moving eCommerce landscape.

See Also

Common Supplier Communication Errors And Ways To Prevent Them

Reasons Suppliers Ignore Emails And How To Get Responses

Best Five Methods To Find Dental Products For Online Stores