Q4 Must-Have: From Factory Direct Supply to Fast Shipping – A One-Stop Service Experience

Q4 is a very busy time. You have short deadlines and lots of orders. People expect a lot from you. If you do not plan well, things can go wrong. Orders might arrive late or get lost. Customers may not be happy. Your business could get a bad name. Bad reviews and lost sales can hurt you after the holidays. You need a Must-Have solution. Use factory direct supply and fast shipping. Be open and honest with your customers. Use real-time tracking and connected systems. This keeps customers happy and orders on time.

Key Takeaways

Q4 has more demand and supply chain risks, so plan your inventory well to stop running out or having too much stock. Factory direct supply saves money and makes delivery faster by sending products from the factory to customers. Use many carriers and spread out warehouses to make shipping quick, flexible, and reliable when it gets busy. Real-time tracking and transparency help customers stay updated, lower complaints, and build trust. Connect your systems and partners to talk better, speed up fulfilment, and stop delays. Get your warehouse and workers ready early with training and automation to handle the Q4 rush easily. Make strong backup plans with extra suppliers, more stock, and flexible shipping to fix sudden problems. Watch key performance indicators and listen to customer feedback to make your Q4 fulfilment better every year.

Q4 Challenges

Demand Surge

Q4 is the busiest time of the year. Sales are twice as high as other times. Big events like Black Friday and Prime Day happen now. Brands spend a lot on marketing during this season. More people shop online and in stores. Everyone wants their orders to arrive quickly. In Q4 2024, online sales went up by 22%. You have to keep up with this fast pace. If you run out of stock, you lose money. If you buy too much, you might waste products. You need to find the right balance. Plan your inventory with care. Look at past sales and current trends to guess demand. Stay ready to change your stock as orders come in.

Q4 brings more shoppers and higher sales.

Stock runs out faster, so shortages are common.

Big shopping days cause sudden jumps in demand.

Supply Chain Risks

Supply chain problems are worse in Q4. Shipping can be slow and cost more. Sometimes factories close for holidays. Trouble in places like the Middle East can block shipping routes. Fuel prices can go up. Tariffs may make you import early, which is hard to plan. Warehouses get full, and there are not enough workers. Packing and shipping orders gets harder. If you do not plan, you may face delays and lose sales. Customers may get upset.

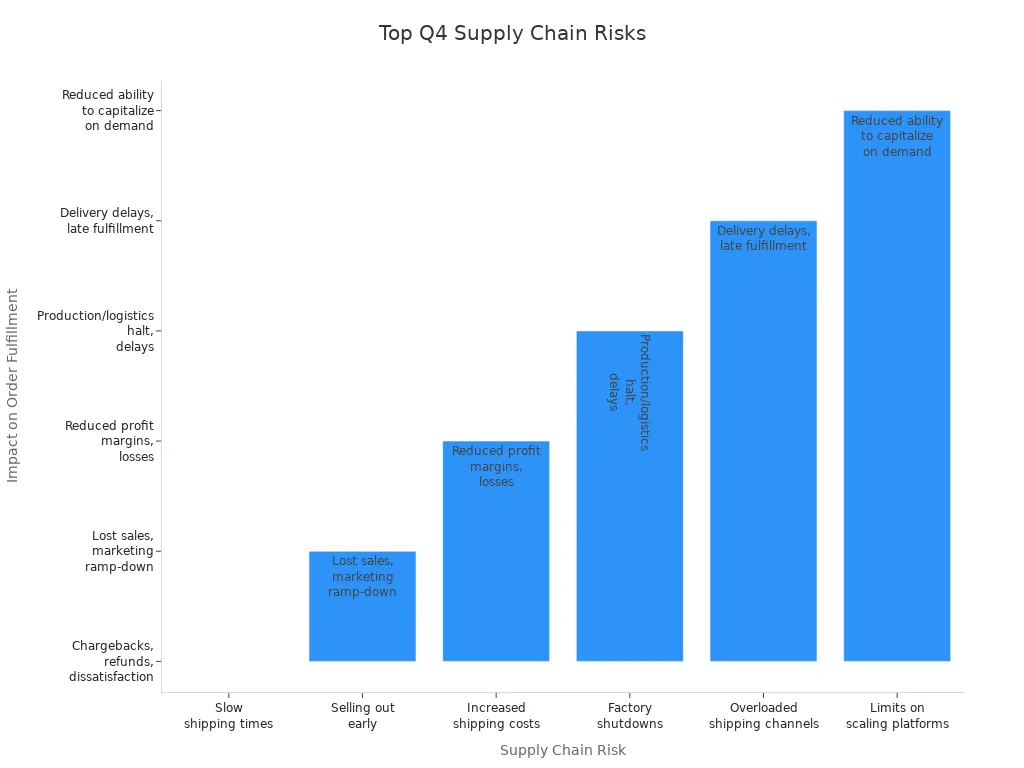

Here is a table of common risks and what they cause:

Supply Chain Risk | Impact on Order Fulfilment | Mitigation Tips |

|---|---|---|

Slow shipping times | Refunds, chargebacks, unhappy customers | Plan early, use more than one carrier |

Selling out early | Lost sales, less marketing | Watch your stock, change your marketing |

Increased shipping costs | Lower profits | Plan for higher costs, talk to carriers |

Factory holiday shutdowns | Production delays | Order early, talk to suppliers |

Overloaded shipping channels | Late deliveries | Use different shipping, automate packing |

Limits on scaling platforms | Missed sales chances | Upgrade systems, test if they can handle more |

Tip: Start planning early. Talk to your suppliers and carriers. Save extra money for surprise costs.

Customer Expectations

Customers want more in Q4. They want fast and correct delivery. They also want many shipping choices. Almost half say on-time delivery is most important. If you miss a delivery or run out of stock, you may lose them. Over half of shoppers have had delays or stockouts. Many will buy from another brand if this happens. Give clear delivery times and real-time tracking. Offer flexible shipping options. Automation in your warehouse helps you work faster and make fewer mistakes.

Real-time tracking keeps shoppers updated.

73% reward shops that meet their needs, but 53% do not return after a bad experience.

Test how fast you can ship before the busy season. Show delivery times at checkout and keep customers informed. If you meet their needs, they will stay loyal and buy more. If not, they may shop somewhere else.

Factory Direct Supply

Cost Benefits

You want to save money in Q4. Factory direct supply helps you do this. Products go straight from the factory to your customers. You skip extra steps and save money. You do not pay for company-owned warehouses. You also avoid extra handling costs. This model cuts out middlemen and lowers costs. It helps most when demand goes up. Orders arrive faster because products do not stop at many places.

Traditional distribution sends products to your warehouse first. You pay for storage and handling. These costs rise quickly in Q4. Bulk shipping discounts can help, but warehousing costs stay high. New network planning and manufacturing make direct supply easier now. You can meet customer needs for fast and correct deliveries. This works even when orders come in quickly.

Tip: Check your supply chain costs before Q4. If warehousing or handling fees are high, try factory direct supply for your top products.

Quality Control

You need strong quality control to keep customers happy. Factory direct supply lets you check quality at the factory. You catch mistakes before products ship out. Ask suppliers for proof of independent product testing. This stops faulty items from reaching customers.

Here are smart ways to boost quality control:

Move quality checks to the factory to spot errors early.

Ask for product testing certificates from outside labs.

Use barcoding and cycle counts to keep inventory correct.

Track order accuracy, fill rate, and processing time.

Know what inventory you own, where it is, and how much.

Automate your warehouse to speed up orders and cut costs.

Hire and train seasonal workers early for Q4 spikes.

If you follow these steps, you will see fewer mistakes. Customers will be happier. You will save money by cutting returns and complaints.

Transparency & Tracking

You want to know where your products are all the time. Real-time transparency and tracking help you do this. IoT devices, RFID tags, and sensors give live updates. You see your inventory and shipments as they move. You can change your fulfilment plan quickly if needed. This helps you avoid delays and errors when orders pile up in Q4.

Order management systems let you talk to all supply chain partners. You break down silos and keep everyone informed. You route orders faster and deliver more accurately. Some retailers have cut order cancellations by 35%. Customer satisfaction went up by 28 points after adding real-time inventory visibility. On-time delivery improved from 76% to 98.5%. Customer service calls dropped by 62%.

Digital logistics platforms help you track orders and deliver faster. Automation and predictive analytics handle thousands of orders each day. Mistakes are rare. You can scale up easily during busy times like Black Friday. Customers see their order status in real time. This builds trust and keeps them coming back.

Note: Real-time tracking is not just nice to have. It is a must-have for Q4. You spot problems early and keep customers happy.

Fast Shipping

When Q4 starts, you must send orders fast. Fast shipping is more than just speed. It means making smart choices and being flexible. You also need to keep your promises. Here are ways to make fast shipping work for you.

Multiple Carriers

You should not use only one carrier in Q4. Using more carriers gives you extra options. This helps you avoid delays. Here is why it matters:

Multi-carrier systems choose the best carrier for each order. They look at speed, cost, and reliability.

You have backup choices if one carrier gets too busy or delayed.

You can avoid extra charges and limits by spreading shipments.

Regional carriers may give better prices for light packages in their areas.

You can change carriers quickly if there is a strike or problem.

Automation saves time by picking the right carrier and filling forms.

You get live tracking and alerts, so you always know where parcels are.

Performance analytics help you find slow spots and improve delivery.

Tip: Add new carriers before Q4 begins. Even late in the season, more carriers give you extra safety and more space.

Here is a quick look at the benefits:

Benefit | What It Means for You |

|---|---|

Flexibility | Change plans and avoid delays |

Cost-effectiveness | Compare prices and save money |

Risk reduction | Switch carriers if problems happen |

Time savings | Automation makes shipping faster |

Better customer service |

Distributed Warehouses

You can ship faster by keeping products near your customers. Distributed warehouses help you do this. Here is how you can use them:

Store stock in different regions to make delivery quicker.

Send orders to the closest warehouse automatically.

Share the work between warehouses to stop slowdowns.

Keep extra stock in key places for sudden spikes.

Shorten shipping distances and lower costs.

Handle supply chain problems better.

Grow quickly when orders go up.

If you use distributed warehouses, you can offer next-day or two-day delivery in more places. You also lower the risk of running out of stock in one area. This keeps your customers happy and coming back.

Note: A hybrid fulfilment plan, using several partners or ways, covers all your needs and lowers risk.

Real-Time Tracking

Customers want to know where their orders are all the time. Real-time tracking helps them feel calm and builds trust. Here is what you get:

Customers get updates by SMS, email, or app. They know exactly when to expect delivery.

Real-time tracking cuts customer service calls by up to 70%.

You can act quickly if there is a delay and keep customers informed.

Customers feel in control and can plan to get their parcels.

Brands with real-time tracking see more loyalty and repeat business.

Almost 9 out of 10 shoppers say real-time tracking makes their experience better. Over half say it makes them want to buy from you again. When you keep your delivery promises, you build trust and stand out in busy Q4.

Keep your customers updated. Real-time tracking is not just a feature—it is a must-have for Q4 success.

Must-Have Fulfilment Checklist

Inventory Planning

You need a solid plan for your Q4 inventory. Start by looking at your sales from last year. Check which products sold best and spot any trends. Use this data to guess how much stock you will need. Don’t just rely on old numbers. Think about new trends and what shoppers want this year. If you use ecommerce tools, you can track your sales rank and adjust your stock in real time.

Here’s a Must-Have checklist for your inventory planning:

Forecast demand using past Q4 sales, current trends, and market research.

Keep extra stock on hand. It’s better to overstock than run out during peak times.

Send inventory early to fulfilment centres like Amazon FBA. Use more than one centre if you can.

Set up a backup plan. If your main fulfilment runs out, switch to another method quickly.

Watch your storage fees. Don’t let products sit too long in warehouses.

Use local warehouses or third-party logistics to keep stock close to your customers.

Bundle products to save on shipping and storage.

Adjust your ads and prices to control how fast your stock sells.

Keep strong ties with your suppliers. This helps you get better prices and faster restocks.

Align your promotions with your inventory. Make sure you have enough stock for big sales days.

Tip: Never ignore your Inventory Performance Index. This score helps you spot problems before they hurt your Q4 sales.

Warehouse Readiness

Your warehouse must be ready for the Q4 rush. You want every order to move fast and smoothly. Start by talking to your fulfilment partners early. Make sure they have enough staff and space for your products. Order your stock as soon as possible to avoid delays.

Here’s how you can get your warehouse Q4-ready:

Audit your inventory. Focus on your top sellers and seasonal items.

Use a Warehouse Management System (WMS) for real-time tracking and restock alerts.

Optimise your warehouse layout. Make picking and packing easy and quick.

Cross-train your team. Everyone should know how to handle busy days.

Build your seasonal workforce early. Train them well before the rush starts.

Prepare for returns. Set up prepaid return labels and automate inspections.

Work with your 3PL to reincorporate returned goods quickly.

Communicate clearly with your customers. Use automated updates and live support.

Align your warehouse capacity with your marketing campaigns. Be ready for sudden spikes.

Monitor your performance. Fix problems before they affect your customers.

Note: Flexible warehousing and smart tech help you scale up fast. This is a Must-Have for Q4 success.

Order Processing

Order processing can make or break your Q4. You want every order to go out fast and without mistakes. Start by reviewing last year’s data. Spot any bottlenecks and fix them now.

Follow these steps for smooth order processing:

Reorder your best sellers early. Don’t wait for stock to run low.

Bundle slow-moving products with popular ones to clear out old stock.

Use real-time inventory systems. This keeps your stock counts accurate.

Integrate your online shops with your warehouse system. Avoid manual uploads.

Automate your pick, pack, and ship process. This saves time and cuts errors.

Offer fast shipping options. Meet the needs of last-minute shoppers.

Prepare for more customer service requests. Train your team and use automated replies.

Clarify your return policies. Make returns easy for your customers.

Communicate shipping deadlines and special packaging needs with your partners.

Start planning early. A Must-Have strategy is to use factory direct supply and fast shipping together. This keeps your orders moving and your customers happy.

If you follow this checklist, you will handle the Q4 rush with confidence. Your fulfilment will be smooth, and your customers will notice the difference.

Shipping Solutions

You want every parcel to get to your customer fast and safe in Q4. Shipping gets hard when lots of orders come in at once. Deadlines get tight and mistakes can happen. You need a strong plan that covers everything. Let’s look at the best ways to ship in Q4.

1. Choose Reliable Carriers

Pick shipping partners who do well when it is busy. Check how far they deliver, how quick they are, and if they help customers well. Good carriers help you keep your word and stop last-minute problems.

2. Diversify Your Shipping Methods

Do not use just one carrier for all orders. Offer different shipping speeds and use more than one company. This gives your customers choices and helps you avoid delays if one carrier is too busy.

3. Plan Early and Forecast Volumes

Start planning before the busy time starts. Guess how many parcels you will send out. Talk to your carriers and make sure they can handle your orders. Get more staff for your warehouse and make your fulfilment process faster.

4. Set Clear Shipping Deadlines

Tell customers when they must order to get parcels on time. Clear deadlines help customers know what to expect and make them buy more. You build trust by giving real delivery dates.

5. Encourage Early Purchases

Run early sales or gift deals to get people to buy sooner. This gives you more time to pack and ship orders. You spread out the work and avoid last-minute rush.

6. Develop a Contingency Plan

Things can go wrong like bad weather or too many orders. Make a backup plan for these problems. List risks like not enough staff or full warehouses. Get ready by hiring extra workers, using other carriers, or keeping stock in local warehouses. Check and update your plan often.

7. Use Smart Packaging

Pick poly mailers for most parcels. They are light, strong, and keep water out. Use the right size so items do not move around. Add bubble wrap for breakable things. Eco-friendly packaging is good for the planet and cuts waste.

8. Communicate and Track

Keep customers updated about their orders. Send messages by SMS or email. Use real-time tracking so shoppers always know where their parcels are. If there is a delay, tell them quickly. Good updates build trust and keep customers happy.

9. Enhance the Unboxing Experience

Make opening a parcel fun and special. Use custom boxes or add a thank-you note by hand. Small touches make customers feel good and make them want to buy again.

10. Collaborate with Shipping Partners

Work closely with your carriers. Share your plans and fix problems together. Quick teamwork keeps things running well and helps you solve issues fast.

Here’s a simple table to check your Q4 shipping solutions:

Shipping Solution | Why It Matters | How-To Tip |

|---|---|---|

Fewer delays, better service | Check reviews and peak season stats | |

Multiple shipping methods | More options, less risk | Add express, standard, and local carriers |

Early planning | Avoid bottlenecks | Forecast volumes and confirm capacity |

Clear deadlines | Happy customers, fewer complaints | Show cut-off dates at checkout |

Contingency plan | Stay ready for surprises | List risks and backup solutions |

Smart packaging | Safe, eco-friendly deliveries | Use poly mailers and bubble wrap |

Real-time tracking | Builds trust, reduces support calls | Send updates and tracking links |

Unboxing experience | Boosts loyalty and reviews | Add personal touches to parcels |

Partner collaboration | Fast problem-solving | Hold regular check-ins with carriers |

Tip: Fast shipping is a Must-Have for last-minute orders. Offer it as a choice to keep your customers happy.

You cannot control every part of shipping, but you can get ready for most problems. Use these Must-Have ideas to keep your Q4 deliveries on time and your customers smiling.

One-Stop Service

Integration

You want everything to work together in Q4. Integration means your supply chain partners, systems, and teams all connect. This makes your fulfilment faster and more reliable. When you link your systems, you can:

Forecast demand together, so you never get caught off guard by a sales rush.

Manage your workforce better. You can hire extra staff or move people where you need them most.

See your stock levels in real time. You always know what you have and what you need to order.

Use automation to speed up picking, packing, and shipping.

Share updates with your partners, so everyone knows what is happening.

Work with fulfilment partners who can scale up quickly and keep things moving.

When you follow these steps, you cut delays and keep your customers happy. You also avoid running out of stock or having too much left over. Integration gives you the control you need during the busiest time of year.

Tip: Start by connecting your order system with your warehouse and shipping partners. This helps you spot problems early and fix them fast.

Communication

Good communication keeps your Q4 running smoothly. You need to talk clearly with your team, your partners, and your customers. Here is how you can do it:

Set clear deadlines for your team. Everyone knows when orders must go out.

Tell your customers about shipping cut-off dates. Use emails, banners on your website, and social media posts.

Let shoppers know what to expect with delivery times. This builds trust and stops complaints.

Plan for big sales days like Black Friday. Make sure your team and partners know the plan.

You can use different tools to help you:

Email works best for most teams. It is simple and everyone uses it.

Video calls help you share updates quickly.

Project management software keeps tasks on track.

Instant messaging lets you solve problems fast.

Mobile apps help your team stay connected, even on the go.

When you work with a fulfilment partner, make sure you both use the same tools. Train your team before Q4 starts. Keep everyone in the loop with real-time updates.

Note: Clear and quick communication stops mistakes and keeps your orders moving.

Customer Experience

You want your customers to have a smooth journey from start to finish. A one-stop service makes this easy. You bring together marketing, sales, and support, so your customer never feels lost. You cut out extra steps and make things simple.

Give your customers one place to get help. No more bouncing between teams.

Reduce the number of forms and follow-up calls. Make it easy to solve problems.

Align your teams so everyone works towards the same goal—happy customers.

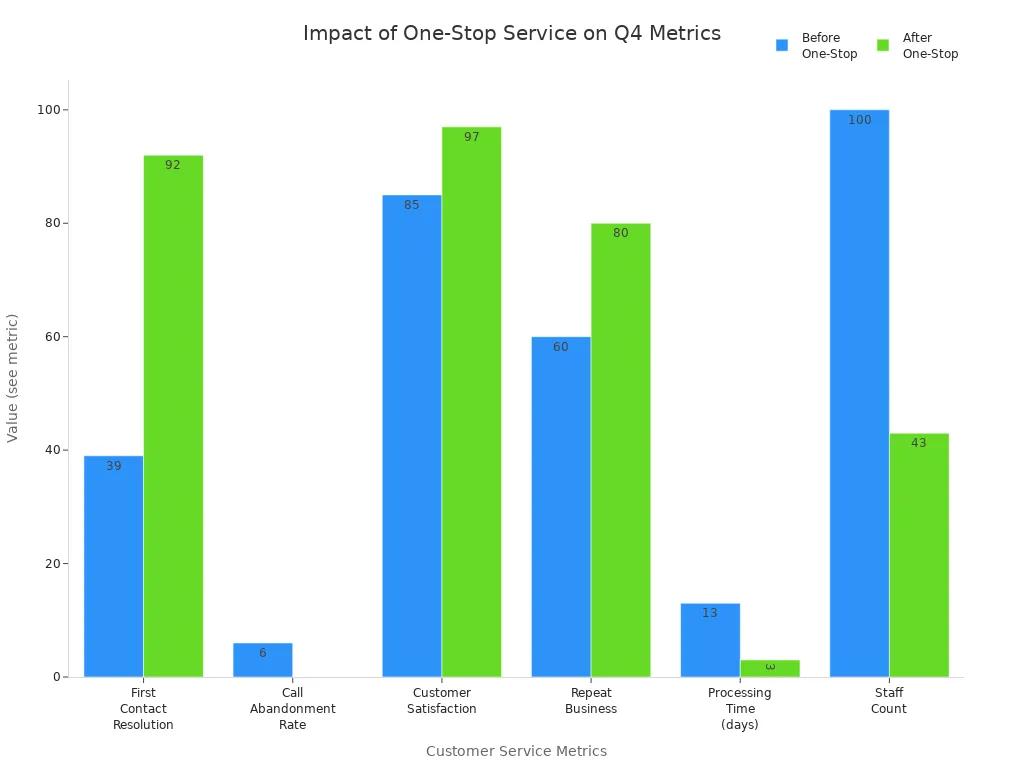

Look at what happens when you use a one-stop service:

Aspect | What Improves | Why It Matters in Q4 |

|---|---|---|

First Contact Resolution | Less waiting, happier customers | |

Call Abandonment Rates | Drop to as low as 0.02% | Customers get help when they need it most |

Customer Satisfaction | Rises to 97% | More loyalty and repeat business |

Repeat Business | Grows to 80% | Keeps your Q4 sales strong |

Processing Times | Cut by up to 67% | Faster service, fewer delays |

Staffing and Cost Savings | Handle more with fewer staff | Save money and scale up for Q4 |

When you make things easy for your customers, they come back again and again. You build trust and stand out from the crowd. In Q4, this can make all the difference.

Remember: A one-stop service is not just about speed. It is about making every step simple and stress-free for your customers.

Implementation Steps

Technology

You need the right technology to keep up with Q4’s fast pace. Start by looking at your current systems. Ask yourself if they help you move products quickly and keep track of every order. Big brands like Amazon and Target use technology and automation to make their fulfilment smoother. You can do the same, even if you run a smaller business.

Use automation tools to speed up picking, packing, and shipping. This cuts down on mistakes and helps you handle more orders.

Try inventory management software. It shows you what’s in stock in real time, so you never run out or over-order.

Add real-time tracking for every parcel. Customers want to know where their orders are at all times.

Look at new tech like AI for smarter forecasting and planning. Generative AI can help you spot trends and plan your stock better.

Connect your systems. Make sure your website, warehouse, and shipping partners all talk to each other.

Tip: Technology is not just for big companies. Even small upgrades can make a big difference in Q4.

Supplier Coordination

You need strong supplier relationships to survive Q4. If you work closely with your suppliers, you can spot problems early and fix them before they hurt your business.

Keep in touch with your suppliers. Regular calls or emails help you hear about delays or shortages before they become big issues.

Share your sales forecasts early. Let your suppliers know what you expect to sell, so they can get ready.

Plan together. Hold joint sessions with your suppliers and logistics partners. This keeps everyone on the same page.

Lock in your production schedules before the busy season. This helps you avoid last-minute surprises.

Always have a backup plan. Find extra suppliers or shipping routes in case your main ones cannot deliver.

Keep a bit more stock than usual. This buffer helps you stay flexible if something goes wrong.

Why It Matters | |

|---|---|

Early communication | Avoids last-minute surprises |

Joint planning | Ensures everyone works together |

Backup suppliers | Reduces risk of running out of stock |

Buffer inventory | Gives you more flexibility |

Note: Good supplier coordination means fewer headaches and more happy customers.

Workforce Planning

Your team is your biggest asset in Q4. You need enough people, with the right skills, ready to work when orders surge. Start by looking at last year’s data. See where you needed more hands and plan ahead.

Forecast your staffing needs based on expected sales. Use data and talk to your department heads.

Start hiring early. Bring in both full-time and temporary staff so you can scale up fast.

Build a pool of trusted workers. Keep in touch with past seasonal staff who did well.

Use automation and AI tools to help your team work smarter, not harder.

Focus on keeping your team happy. Offer incentives and keep communication open.

Make sure you follow all labour laws and get ready for year-end checks.

A happy, well-prepared team will help you deliver every order on time, even when things get busy.

Contingency Plans

You cannot always guess what will happen in Q4. Bad weather might cause trouble. Suppliers could be late. Warehouses might get too full. To keep orders moving, you need strong backup plans. Here is how you can get ready for anything.

Start with these steps:

Diversify your supplier base. Do not use only one supplier. If one has a problem, you can switch fast. Make friends with backup suppliers before Q4.

Strengthen communication. Talk often with suppliers, partners, and customers. If something goes wrong, you can fix it together. Use instant messages and regular check-ins.

Optimise your inventory. Keep some extra stock, but not too much. If demand jumps or a shipment is late, you will have enough. Balance just-in-time and buffer stock.

Embrace technology. Use real-time tracking and automation. You will spot problems as soon as they happen. Tools like inventory software and live updates help you stay ahead.

Develop a risk management plan. List risks like bad weather or late suppliers. Write down what you will do if each one happens. Share your plan with your team.

Tip: Book container space early. Talk to carriers before the rush. This helps you avoid extra costs and delays.

Here’s a table to help you build your Q4 contingency plan:

Action | Why It Matters | How-To Tip |

|---|---|---|

Diversify suppliers | Stops you running out of stock | Find backup suppliers now |

Real-time tracking | Spots delays quickly | Use live shipment updates |

Buffer stock | Handles sudden demand | Store extra stock in key places |

Keeps deliveries on time | Work with flexible delivery fleets | |

Flexible warehousing | Stops warehouse jams | Use extra space during busy times |

Last-mile delivery backup | Fixes city delivery problems | Use local couriers and micro-centres |

Regular planning meetings | Keeps teams working together | Plan cross-team check-ins |

You should send extra stock before Q4 gets busy. This makes things easier when orders rise. Make a holiday shipping guide. After Q4, check what worked and what did not. Use what you learn to do better next year.

Note: No plan is perfect, but a good backup plan keeps you calm when things go wrong. You will deliver on time, keep customers happy, and protect your reputation.

If you follow these steps, you will be ready for anything Q4 brings. You will spot problems early, fix them fast, and keep your business running well.

Continuous Improvement

KPIs

You want to know if your Q4 fulfilment worked well. Tracking key performance indicators (KPIs) helps you spot problems and improve next time. Start by choosing the right KPIs for your business. Here are some you should watch:

On-time delivery rate: Shows how often you deliver orders when promised.

Delivery success rate: Tells you how many orders arrive without needing a second attempt.

Cost per delivery: Helps you see if you are spending too much on each parcel.

Customer satisfaction score: Measures how happy your customers feel after delivery.

Delivery density: Counts how many deliveries you make in one area, which can lower costs.

Failed delivery rate: Points out issues with addresses or missed deliveries.

Average time per stop: Tracks how quickly your team drops off each parcel.

Package condition upon arrival: Checks if parcels arrive undamaged.

Backordered units: Shows if you ran out of stock when customers ordered.

Lead time variability: Tells you if suppliers deliver on time or not.

Service level: Measures how often you fulfil orders without running out of stock.

Stock turnover rate: Shows how quickly you sell and replace inventory.

Inventory aging: Tells you how long products sit in your warehouse.

Perfect order rate: Counts orders that arrive on time, complete, and undamaged.

Tip: Review these KPIs weekly during Q4. You will catch issues early and keep your fulfilment running smoothly.

Customer Feedback

Listening to your customers helps you improve your Q4 fulfilment. You can collect feedback in many ways. Try these steps:

Send short surveys after each purchase. Keep questions simple and quick.

Ask for feedback right after delivery or support calls. This gets honest answers.

Offer small rewards, like discount codes, to encourage replies.

Make sure surveys work well on phones and tablets.

Personalise requests by using your customer’s name and order details.

Give clear instructions so customers know how to share their thoughts.

Test your feedback methods often. Change them if you get few replies.

Always thank customers for their feedback. Tell them what you changed because of their ideas.

You can also use automated tools to collect feedback and spot trends. If you see lots of complaints about late deliveries, you know where to focus. Positive feedback helps you see what works well.

Note: Closing the feedback loop builds trust. Customers feel valued when you listen and act on their suggestions.

Post-Q4 Review

After Q4 ends, you need to look back and learn. A good review helps you get better every year. Here’s how you can do it:

Gather feedback from your team, customers, and partners. Use surveys, meetings, and self-evaluations.

Hold open discussions with your staff. Let everyone share ideas and problems.

Set new goals for next year. Make them SMART: specific, measurable, achievable, relevant, and time-bound.

Involve your whole team in planning. This builds ownership and teamwork.

Write down what worked and what did not. Keep records for future reference.

Use software to track performance and feedback. This makes it easy to spot patterns.

Reflect on your yearly objectives. Did you meet your targets? What stopped you?

Do a SWOT analysis. List your strengths, weaknesses, opportunities, and threats.

Break big goals into small steps. Set deadlines and milestones.

Prioritise tasks using simple tools like the Eisenhower Matrix.

Review Step | Why It Matters | How-To Tip |

|---|---|---|

Team feedback | Finds hidden problems | Hold group meetings |

SMART goals | Keeps you focused | Write clear, simple targets |

SWOT analysis | Spots risks and strengths | List four key areas |

Action steps | Makes goals achievable | Set deadlines for each step |

Prioritisation | Focuses on what matters most | Use a matrix or checklist |

Remember: Continuous improvement means you always look for ways to get better. Your Q4 will run smoother every year if you review, listen, and act.

You want your Q4 fulfilment to work well every year. A one-stop service gives you important benefits. You save money because storage costs are simple. You do not pay extra during busy times. Automated inventory replenishment keeps your stock moving. This stops you from running out of products. You can send orders from all your sales channels using one inventory pool. You have better control and can see what is happening, even if supply chains get tricky. Your business gets stronger and can grow more easily. Start now and keep making things better. You will be ready for every busy season.

Storage is cheap and you only pay for what you use

Stock moves and refills by itself

You can send orders from many places using one stock

Your business can grow and handle problems in the future

Act now. Make your Q4 plan better and build a supply chain that gets stronger every year.

FAQ

What is factory direct supply and how does it help me in Q4?

Factory direct supply means you get products straight from the manufacturer. You skip middlemen. This saves you money and time. You can restock faster and keep up with Q4 demand.

How can I make my shipping faster during peak season?

You can use more than one carrier. Store products in different warehouses. Automate your order process. Real-time tracking helps you spot delays early. Fast shipping keeps your customers happy.

What should I do if my main supplier cannot deliver on time?

Always have backup suppliers ready. Keep extra stock for emergencies. Talk to your suppliers often. If you spot a delay, switch to your backup quickly. Stay flexible and act fast.

How do I keep customers updated about their orders?

Send automatic updates by email or SMS. Use real-time tracking links. Show delivery times at checkout. If there is a delay, let customers know right away. Clear updates build trust.

What is the best way to handle returns in Q4?

Set up an easy return process. Use prepaid labels. Automate return approvals. Restock returned items quickly. Tell customers how to return items. A simple process keeps shoppers coming back.

Can I use one system for all my sales channels?

Yes, you can. Use an integrated order management system. This lets you track stock, process orders, and ship from one place. You save time and avoid mistakes.

How do I prepare my team for the Q4 rush?

Hire extra staff early. Train everyone before the busy season. Cross-train your team so they can help in different areas. Keep everyone updated with daily meetings. Happy teams work faster.

What KPIs should I track to measure Q4 success?

Watch your on-time delivery rate, customer satisfaction, and stock levels. Track how many orders arrive without problems. Use these numbers to spot issues and improve your process.

TangBuy: A Smarter Way to Dropship in 2025

If you're looking to stay competitive with dropshipping in 2025, speed and trend-awareness are key. TangBuy helps you stay ahead with real-time product trends, fast fulfilment, and factory-direct sourcing. With over 1 million ready-to-ship items, 24-hour order processing, and seamless Shopify integration, TangBuy makes it easier to test, scale, and succeed in today's fast-moving eCommerce landscape.

See Also

Five Key Advantages Of Dropshipping Pet Toys Quickly

Best Five Methods To Find Dental Products Online 2025

Guide To Procuring Wholesale Party Supplies From Reliable Sellers